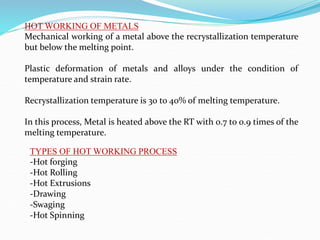

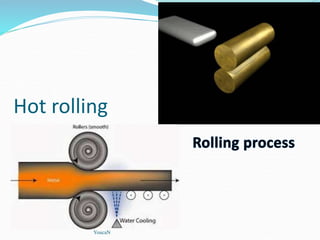

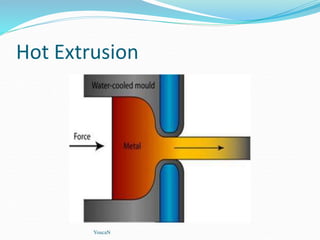

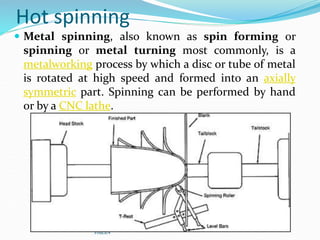

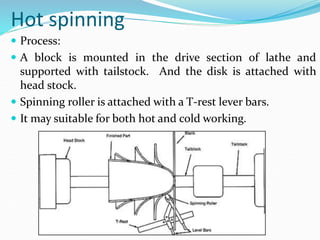

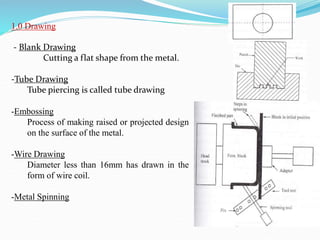

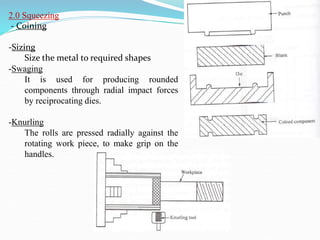

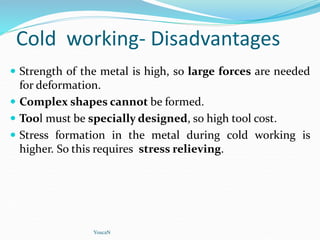

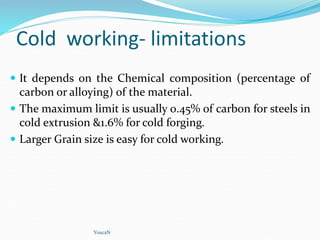

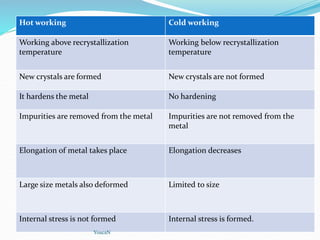

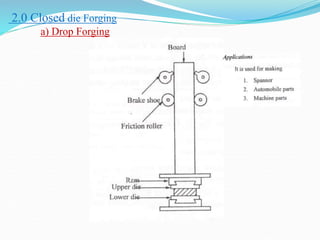

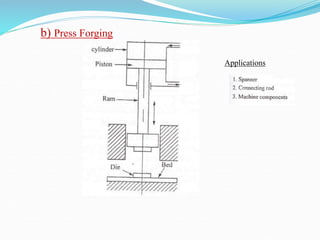

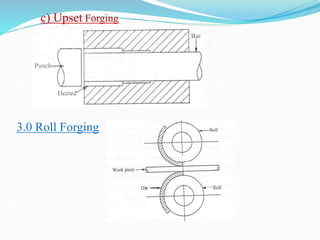

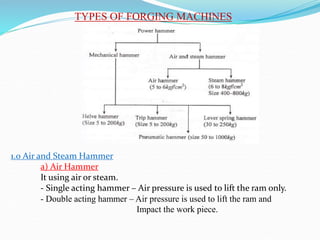

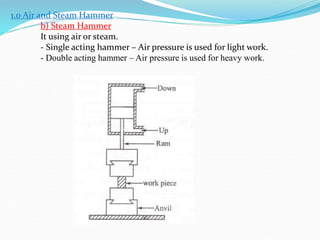

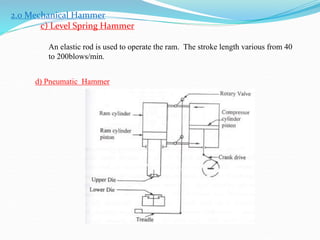

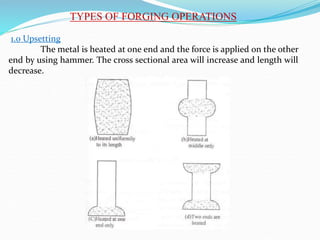

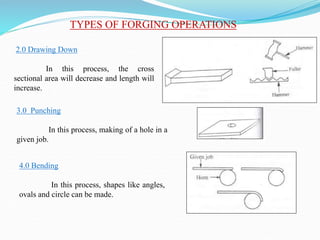

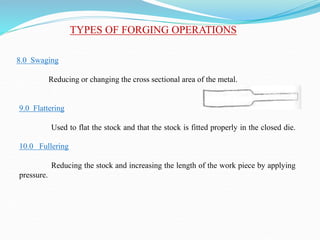

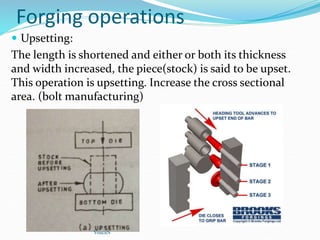

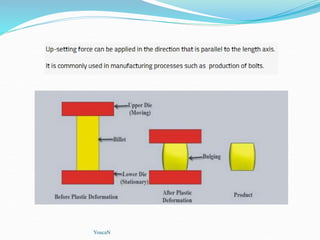

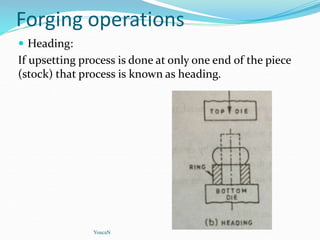

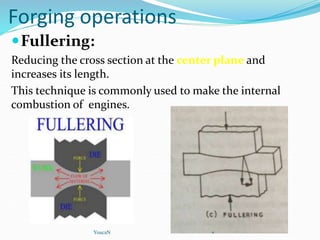

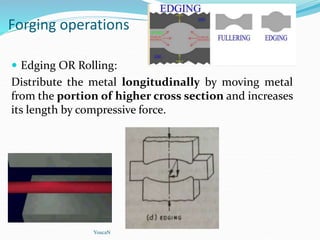

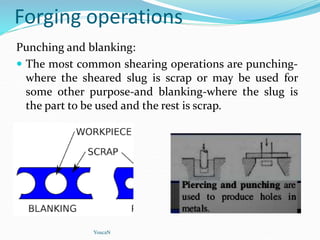

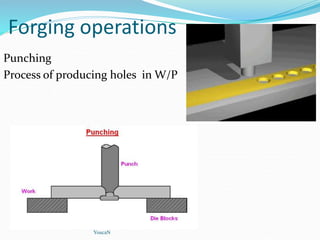

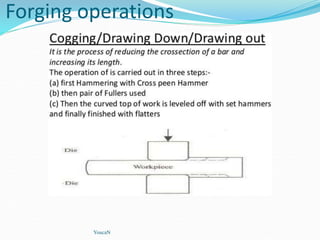

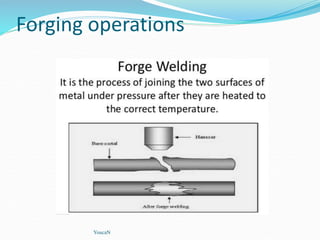

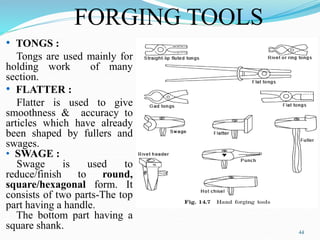

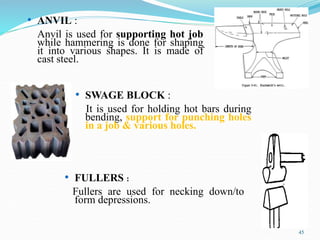

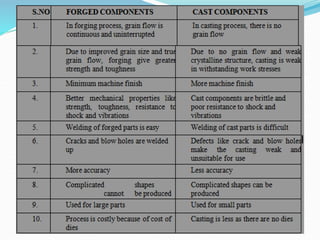

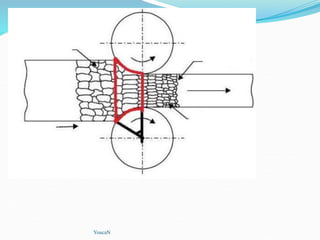

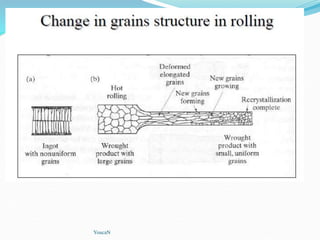

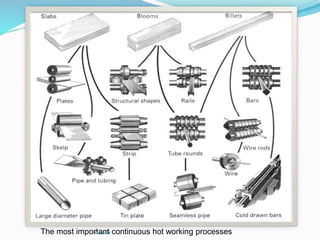

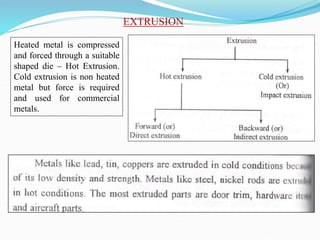

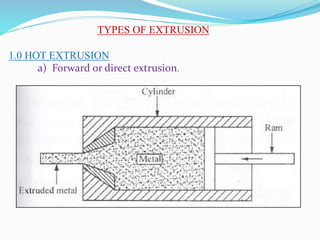

Metal forming processes involve hot working and cold working of metals. Hot working involves mechanically working metals above their recrystallization temperature through processes like forging, rolling, extrusion, drawing, and spinning. Forging is done using open die forging or closed die forging. Common forging operations include upsetting, drawing down, blocking, fullering, and cutting. Cold working is done below the recrystallization temperature through processes like drawing, squeezing, and bending. Defects in forged metal parts can include cracking, laps, cold shuts, warping, and improperly formed sections.