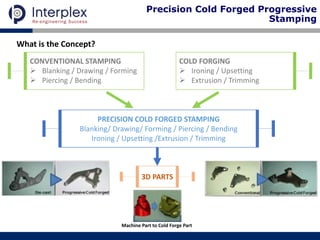

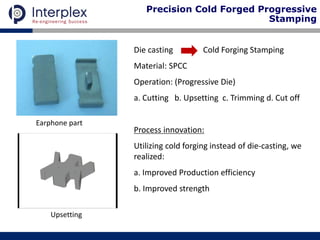

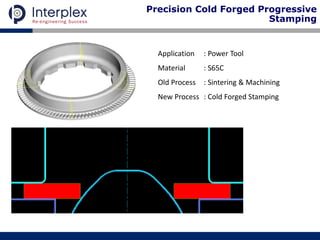

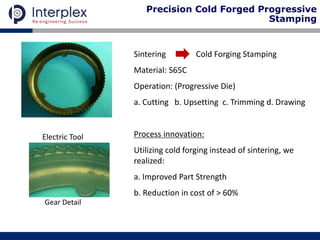

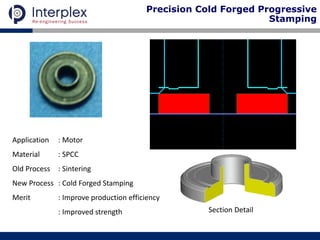

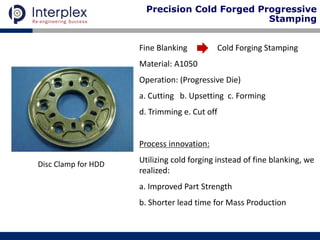

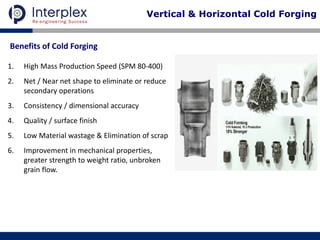

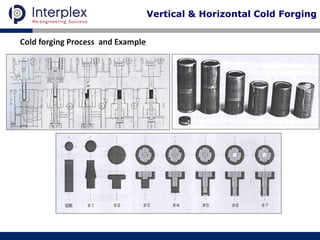

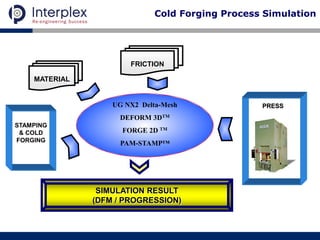

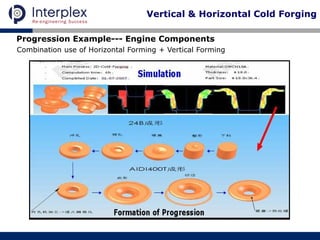

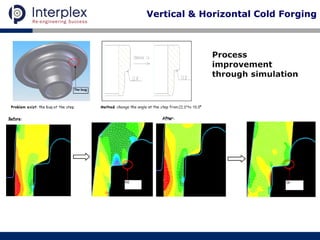

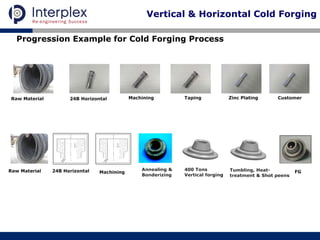

This document discusses cold forging and precision cold forged progressive stamping techniques. It provides examples of using these techniques to produce high-quality 3D metal parts for applications such as electronics components, power tools, hard disk drives, and automotive components. Cold forging allows producing parts with precision flatness, sharp edges, corners, and material thickness control. It provides benefits over conventional techniques like die casting, sintering, and machining, including higher production efficiency, part strength, and dimensional accuracy while reducing costs and waste. Simulation software is used to design cold forging processes and tools.