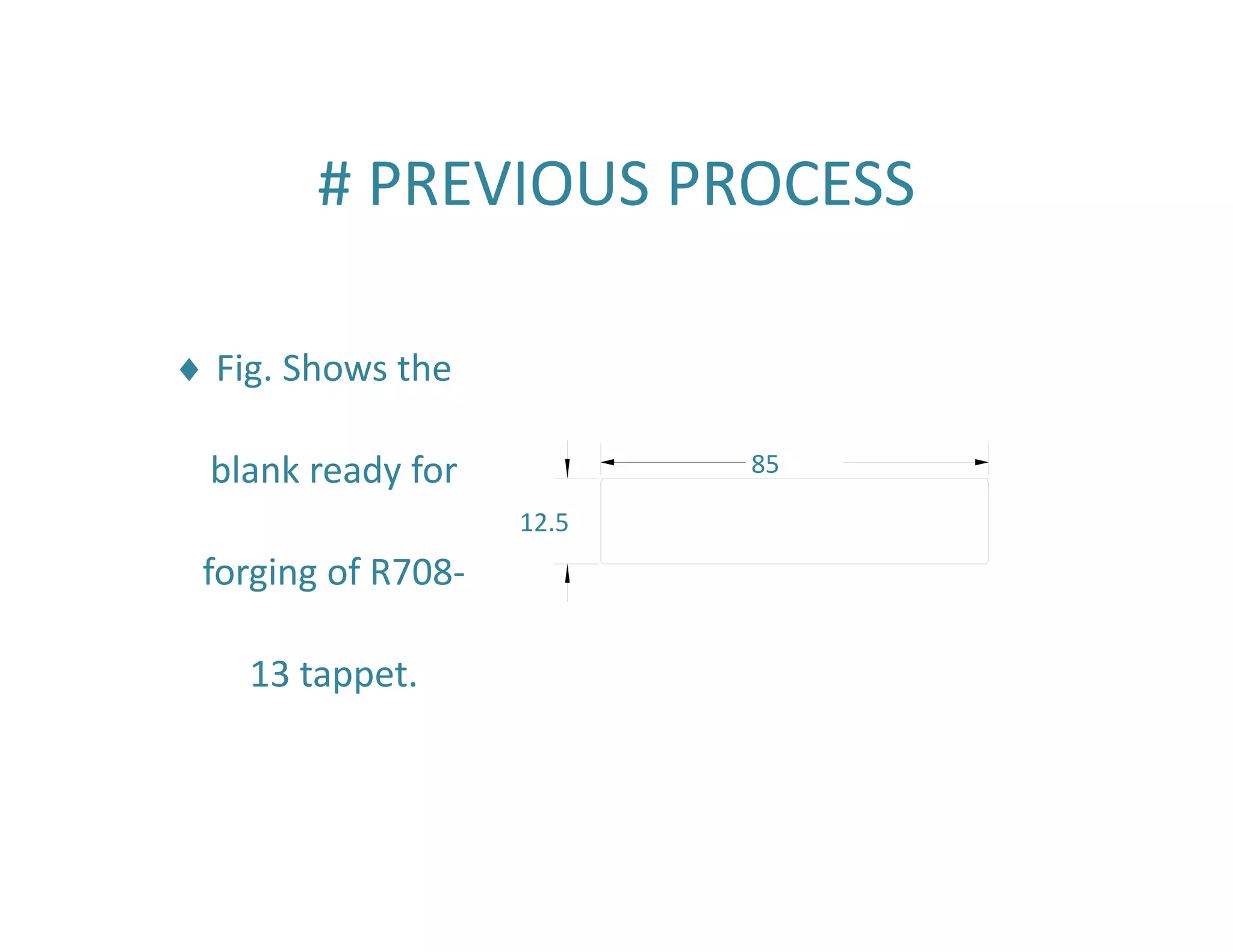

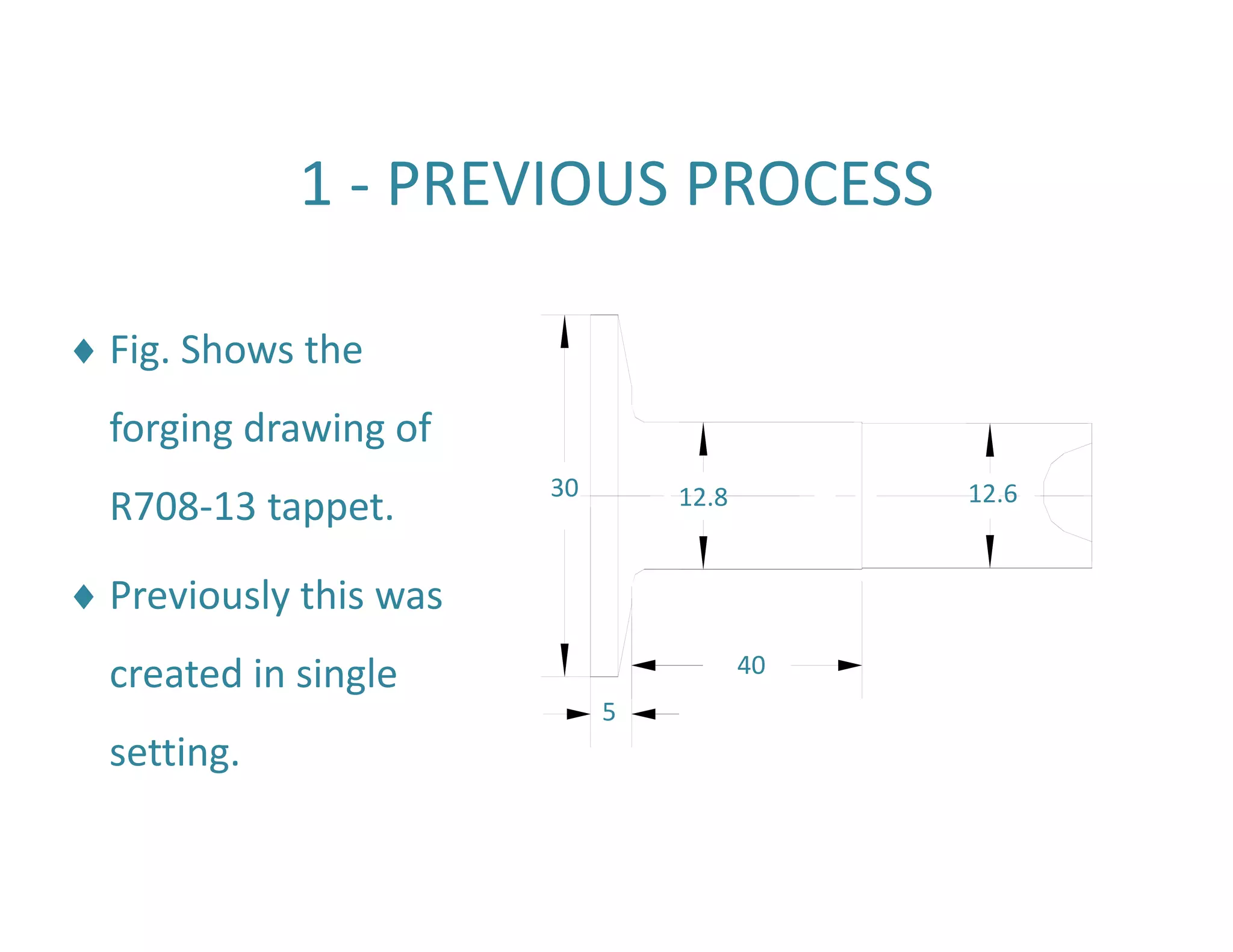

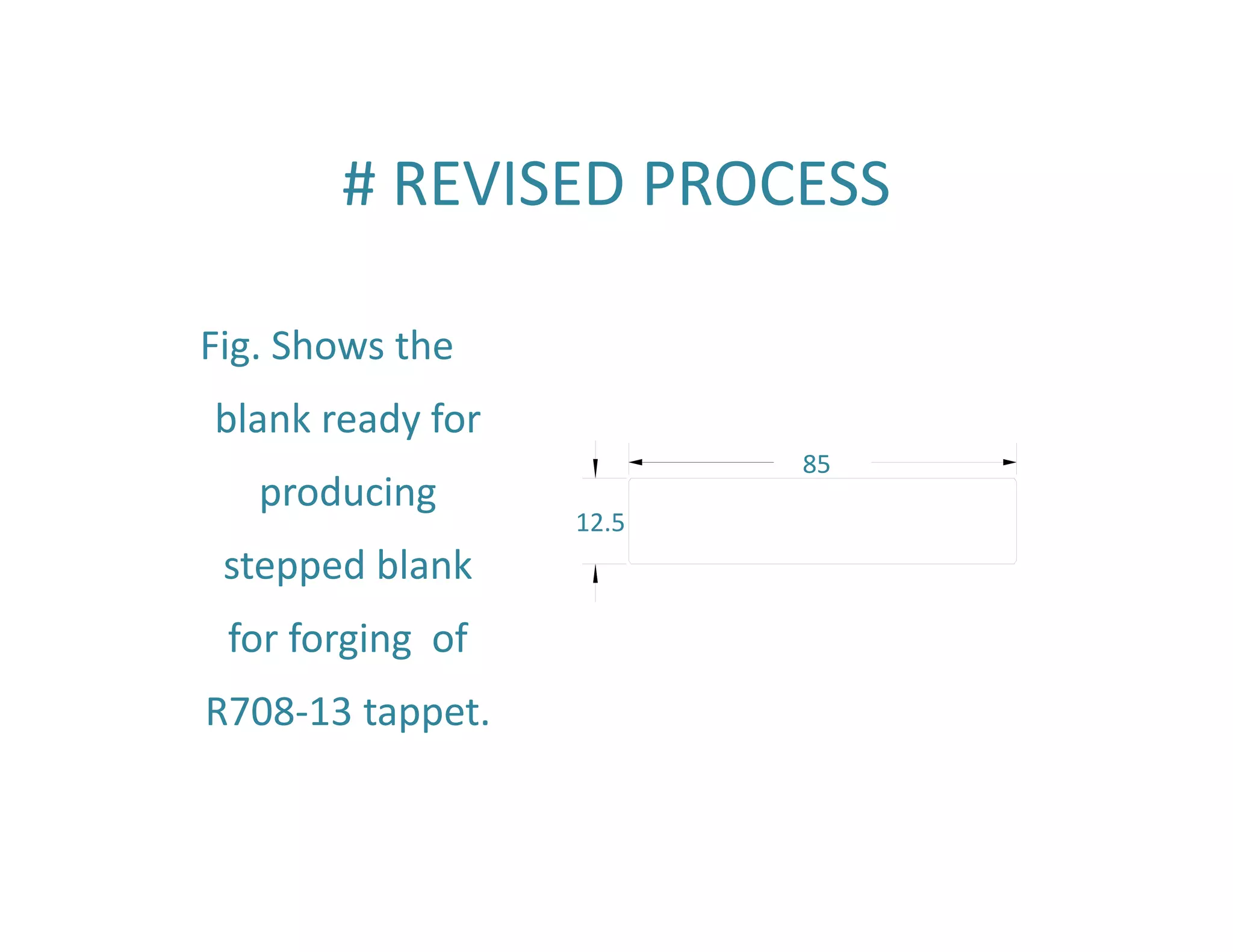

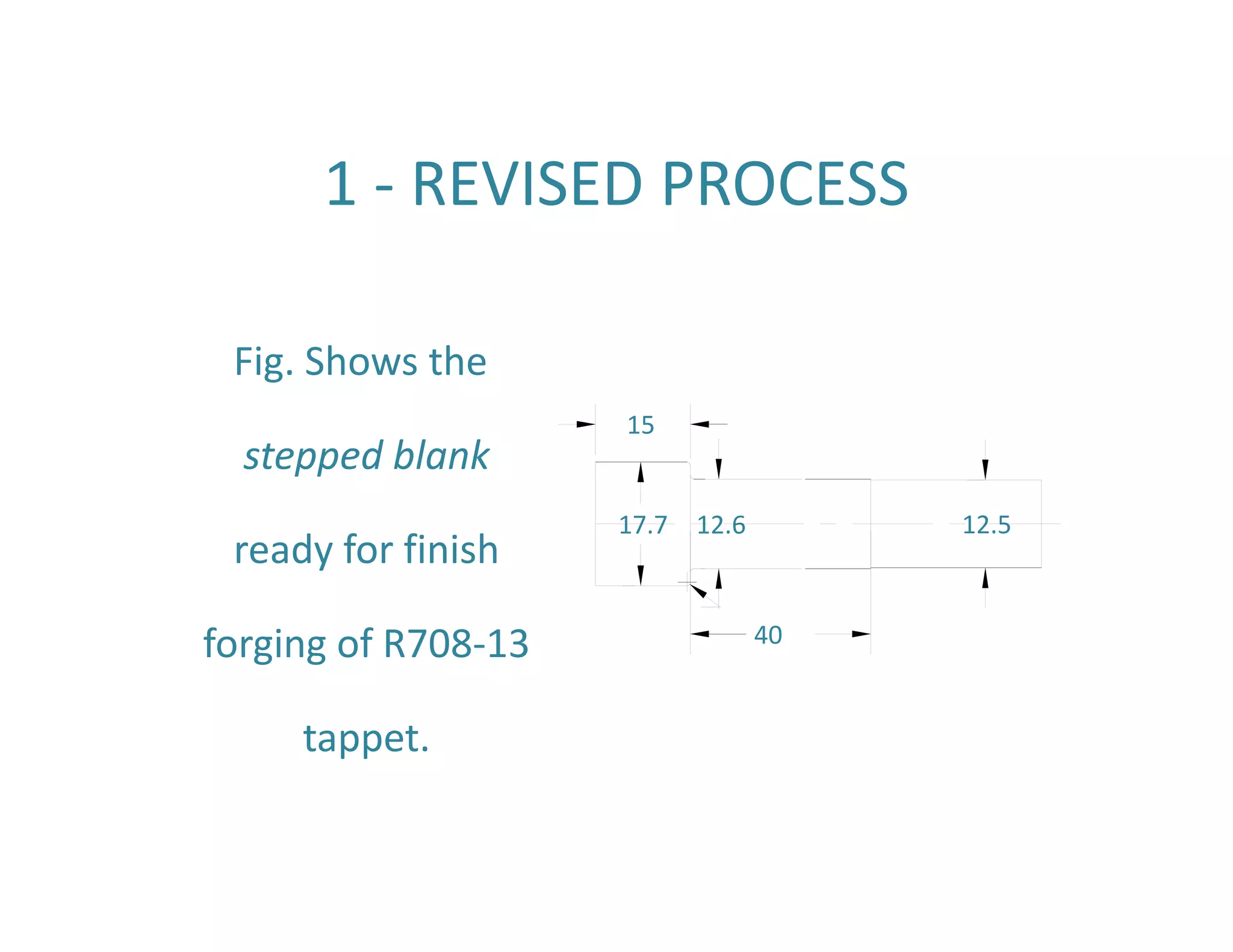

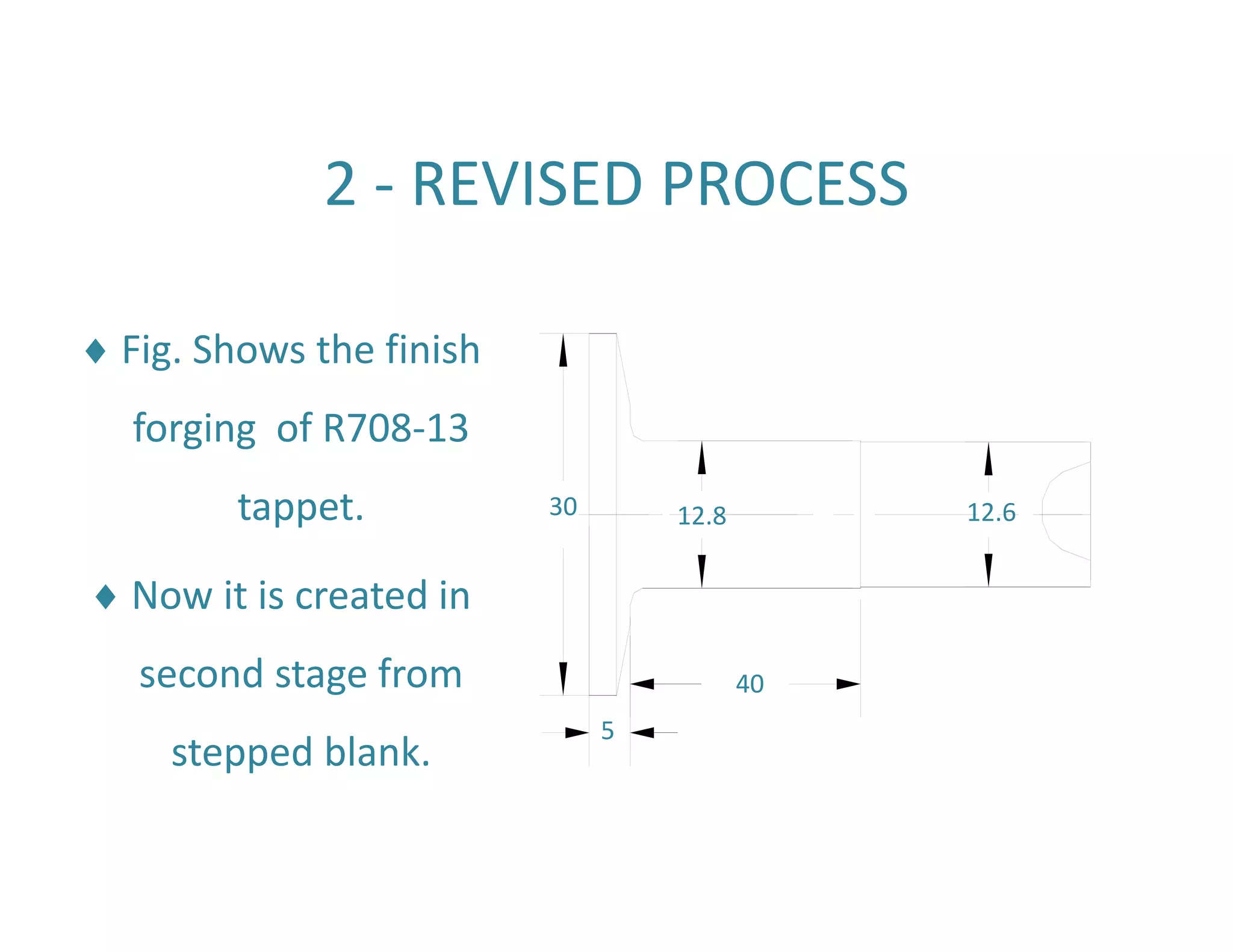

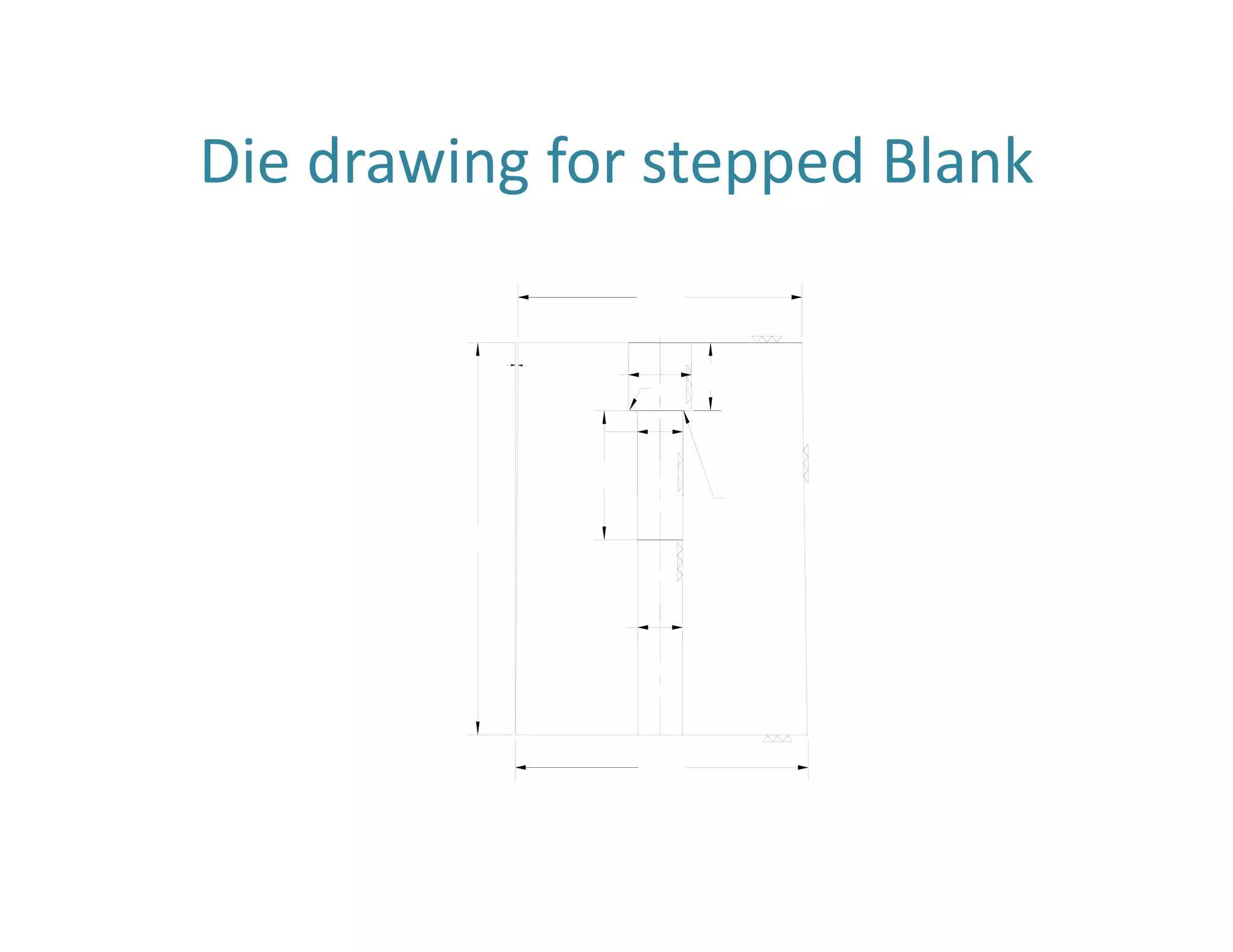

The document discusses redesigning the cold forging process and tooling for producing a valve tappet part. The original single-stage process resulted in inconsistent and excessive head offsetting. Analyzing the process found the D2/d2 and l/d ratios exceeded standards. Recalculations determined a two-stage process with an intermediate stepped blank was needed. Trials with new tooling produced satisfactory results with low, consistent head offsetting. Implementation of the redesigned two-stage process and tooling solved the issues, improved dimensions consistency, reduced setup time and waste.

![INTRODUCTION

The problem of head offsetting while cold forging of item R 708‐13 is observed

in since new product development.

To avoid the same several corrective actions [short method] were initiated such

as using flat ejector etc. but effectiveness of the actions taken was not 100%

satisfactory. The results were not consistent.

After all above it is concluded to analyze and re‐design of cold forging tooling &

process.

While analyzing the same whatever the calculations, observations and the

actions taken by undersigned are recorded here, which will be one guide line to

attend this kind of problems in future.

A. T. ANASRI

Date : 22.08.2000](https://image.slidesharecdn.com/13aacoldforging-141025131617-conversion-gate01/75/Cold-forging-Process-and-Product-Development-Case-study-3-2048.jpg)