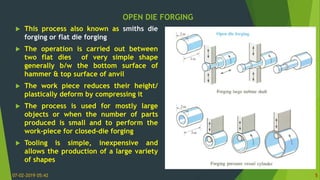

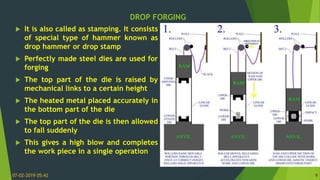

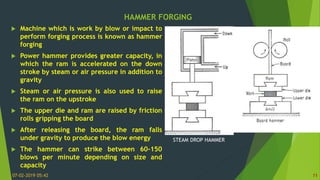

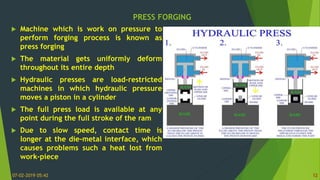

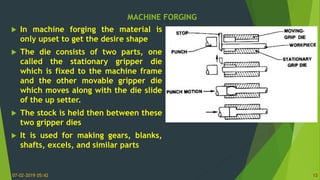

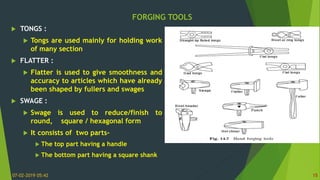

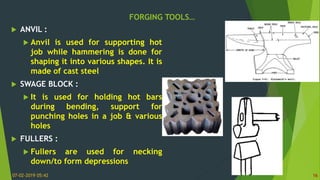

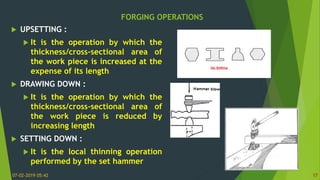

This document discusses various manufacturing technologies related to forging. It describes forging as a metalworking process involving plastic deformation between dies to achieve a desired shape. Forging can be classified based on the process (open die or closed die) or equipment (drop, power hammer/press, hand, or machine forging). The document outlines the key characteristics and applications of these different forging methods. It also describes various forging tools and common forging operations like upsetting, drawing down, setting down, bending, punching, welding, and cutting.