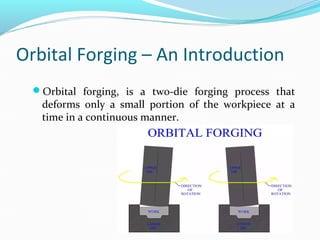

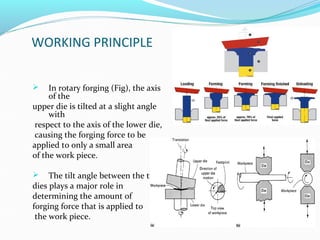

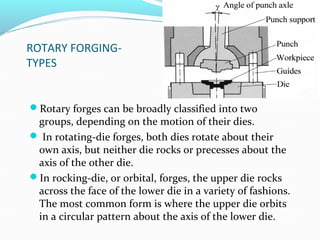

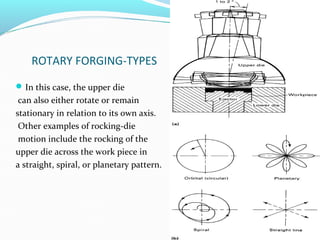

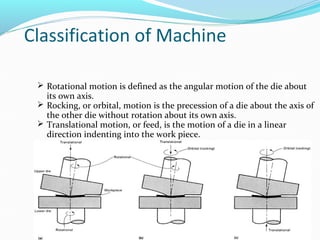

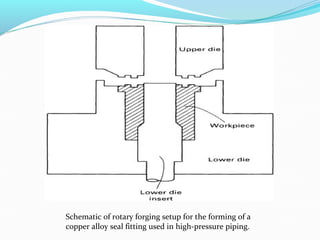

The seminar report discusses rotary or orbital forging, a two-die forging process that deforms a small portion of the workpiece in a continuous manner. It details the working principles, advantages such as reduced material waste and improved material strength, and limitations like the complexity of machine design. The document also covers applications in industries like automotive and aerospace, as well as suitable materials and die specifications.