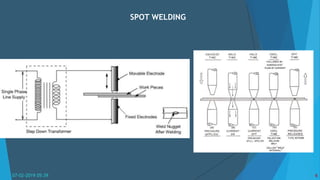

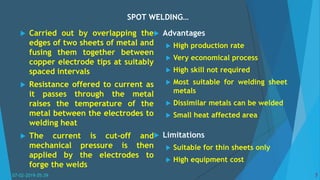

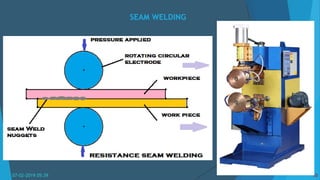

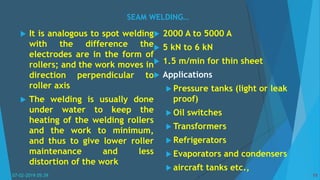

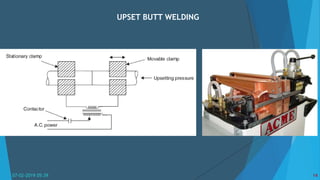

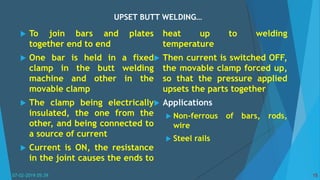

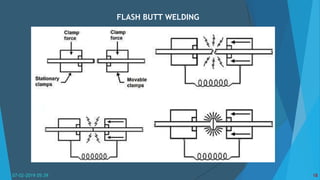

This document discusses various types of resistance welding, including spot welding, seam welding, upset butt welding, and flash butt welding. Spot welding involves overlapping metal sheets and applying a current between electrode tips to generate heat and fuse the metals. Seam welding is similar but uses roller electrodes to continuously weld as the work moves. Upset butt welding joins bars end to end by heating the joint with current and then pressing the parts together. Flash butt welding clamps the parts, applies a current to burn away material, then increases speed and pressure to upset the weld once welding temperature is reached. Resistance welding offers advantages like high production rates and suitability for thin sheets and dissimilar metals.