Embed presentation

Downloaded 44 times

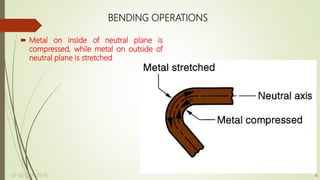

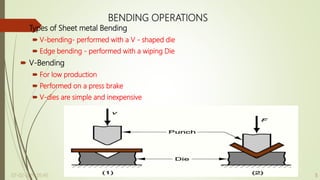

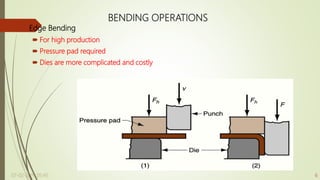

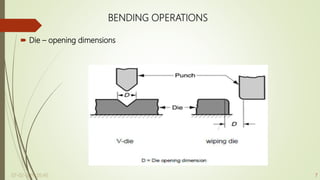

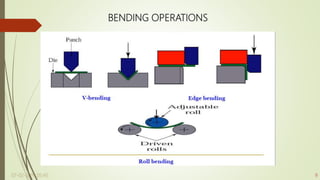

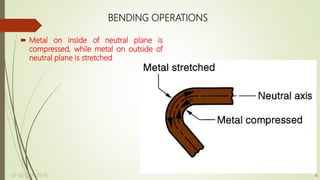

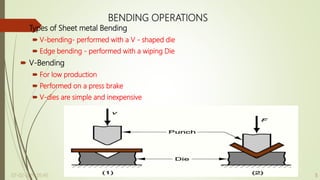

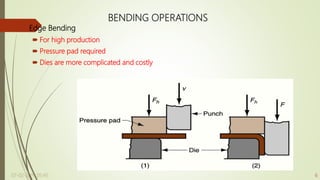

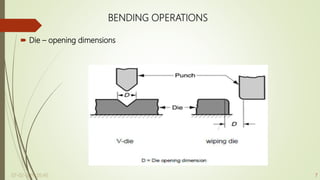

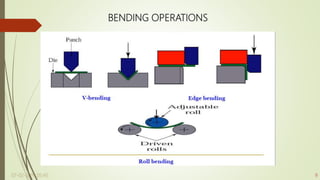

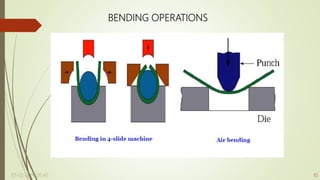

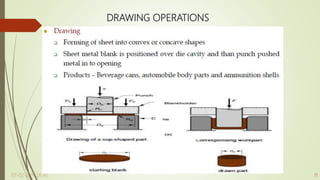

The document discusses bending operations in sheet metal manufacturing. There are two main types of bending: V-bending and edge bending. V-bending is done with a V-shaped die for low production, while edge bending uses a pressure pad and more complex dies for high production. When metal is bent, the inside of the neutral plane is compressed and the outside is stretched. After bending, springback occurs as the bent part partially recovers toward its original shape due to residual elastic energy.