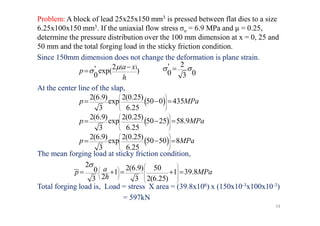

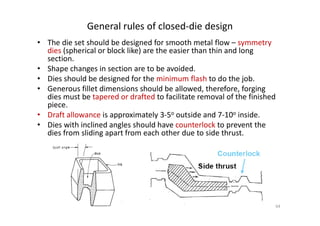

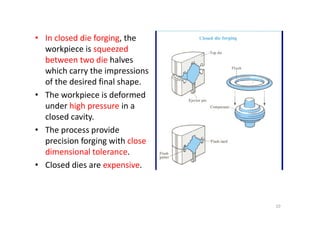

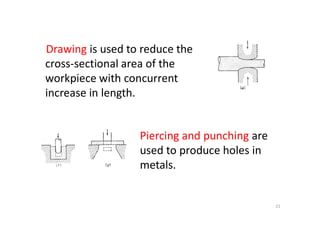

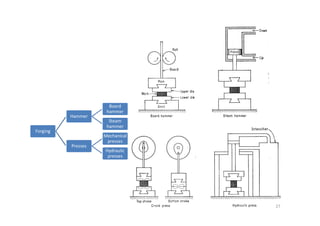

This document provides an overview of forging processes and equipment. It discusses the classification of forging into open die and closed die forging. Open die forging involves compressing metal between flat or simple shaped dies, while closed die forging uses shaped dies to form the final part geometry. The document also describes common forging operations, equipment like hammers, presses, and defects that can occur during forging. It provides examples of industrial forging applications and factors that influence the forging process.

![• The total energy supplied during the stroke of a press

is given by

Where I is moment of inertia of the flywheel

]

2

2

0

[

2

1

f

I

w

Where I is moment of inertia of the flywheel

ω is angular velocity, ωo-original, ωf-after deformation

• Load rating 300 – 12,000 tons

36](https://image.slidesharecdn.com/metal-forming-unit-2-240203215240-2d201401/85/Metal-forming-Unit-2-1-pdf-36-320.jpg)

![Integrate the above equation,

Apply boundary condition, xa σx=0 and

p=σ0’. Therefore,

h

dx

p

dp

2

c

h

x

p ln

2

ln

2

'

2

2

'

0

ln

ln

ln

2

'

0

ln

ln

a

x

h

a

C

C

h

a

p

The mean forging pressure is,

If the ratio a/h increases, the forming

pressure p and forming load rises rapidly .

h

a

p

a

h

x

h

ax

x

a

p

a

dx

h

x

a

a

a

a

pdx

p

1

'

0

0

2

2

'

0

0

]

2

1

[

'

0

0

Usually μ is small number, ey=1+y+y2/2!+…

)

2

exp(

'

0

'

0

ln

2

ln

2

'

0

ln

2

ln

h

x

a

p

h

x

a

p

h

a

h

x

p

]

2

1

[

'

0 h

x

a

p

pressure p and forming load rises rapidly .

Fig.: Distribution of normal stress and

longitudinal stress for compression

between plates.

51](https://image.slidesharecdn.com/metal-forming-unit-2-240203215240-2d201401/85/Metal-forming-Unit-2-1-pdf-51-320.jpg)