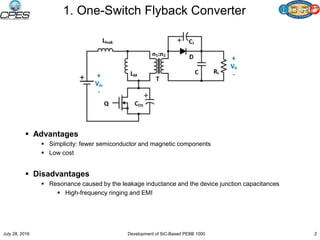

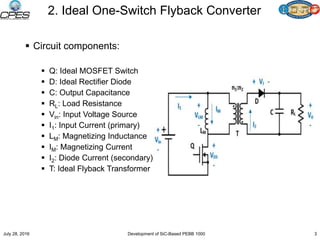

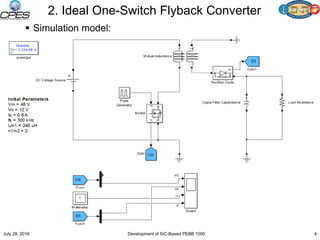

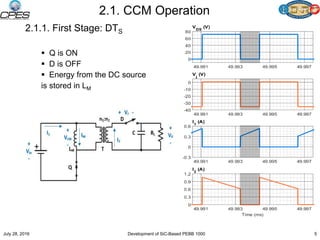

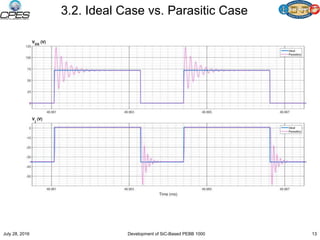

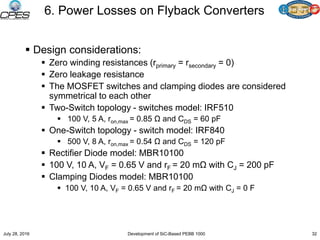

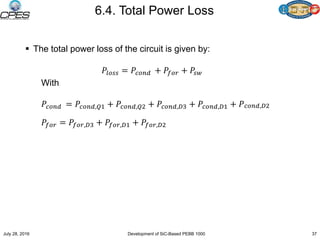

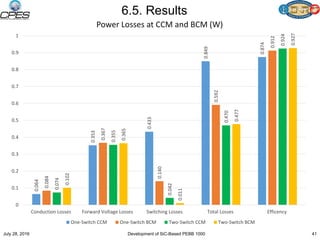

This document describes the operation and modeling of one-switch and two-switch flyback converters. It discusses the ideal and non-ideal cases, comparing the circuits with and without parasitic components. The one-switch converter has issues with resonance from leakage inductance, while the two-switch topology clamps voltages and recycles leakage energy. Simulation models of the circuits are presented, showing the effects of parasitic capacitances and inductances. Component mismatches and their impacts are also analyzed. Finally, losses including conduction, forward voltage, and switching are calculated and compared between the converter designs.

![6.3. Switching Losses

Switching Losses on the MOSFET switches can be obtained by

the simplified formulation presented on [4]:

𝑃𝑠𝑤,𝑄1 =

1

2

𝑓𝑠𝑤 𝐶 𝐷𝑆1 𝑉𝐷𝑆1

2

𝑃𝑠𝑤,𝑄2 =

1

2

𝑓𝑠𝑤 𝐶 𝐷𝑆2 𝑉𝐷𝑆2

2

And

𝑃𝑠𝑤,𝑄1 = 𝑃𝑠𝑤,𝑄2 = 𝑃𝑠𝑤

July 28, 2016 Development of SiC-Based PEBB 1000 36](https://image.slidesharecdn.com/046c3250-bb48-40a6-943a-78521dc87700-160728220545/85/Flyback-Converters-v4-36-320.jpg)

![8. References

[1] “Improving the Performance of Traditional Flyback-Topology With Two-Switch –Approach”, J.

Pesonen; Texas Instruments

[2] “Understand Two-Switch Forward/Flyback Converters”, Y. Xi, R. Bell; National Semiconductor

[3] “Hard-Switching and Soft-Switching Two-Switch Flyback PWM DC-DC Converters and Winding

Loss due to Harmonics in High-Frequency Transformers”, D. M. Bellur, Wright State University

[4] “Two-Switch Flyback PWM DC-DC Converter in Continuous-Conduction Mode”, D. M. Bellur, M.

K. Kazimierczuk, Wright State University

[5] “Fundamentals of Power Electronics”, R. W. Erickson, D. Maksimovic, University of Colorado

Boulder

[6] “Characterization and Modeling of High-Switching-Speed Behavior of SiC Active Devices”,

Zheng Chen; Virginia Polytechnic Institute and State University

[7] “AN-9010 MOSFET Basics”, Fairchild Semiconductor

[8] “Analysis of SiC MOSFETs under Hard and Soft-Switching”, M. R. Ahmed, R. Todd, A. J.

Forsyth, The University of Manchester, UK

[9] “Power Electronics - A First Course”, N. Mohan, University of Minnesota

[10] “Development of an Isolated Flyback Converter Employing Boundary-Mode Operation and

Magnetic Flux Sensing Feedback”, M. V. Kenia, Massachusetts Institute of Technology

July 28, 2016 Development of SiC-Based PEBB 1000 44](https://image.slidesharecdn.com/046c3250-bb48-40a6-943a-78521dc87700-160728220545/85/Flyback-Converters-v4-44-320.jpg)