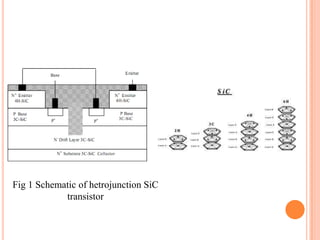

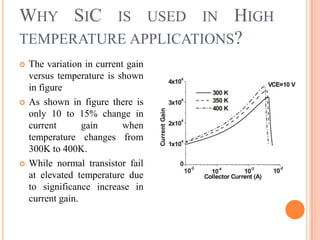

This document discusses the potential for silicon carbide (SiC) in power electronics applications. SiC has a wide bandgap that allows transistors to operate at higher voltages, temperatures, and frequencies than silicon. Its main advantages are higher power density, lower losses, smaller components, and reliability at elevated temperatures. The document outlines SiC applications in renewable energy systems, motor drives, and other industrial uses. However, a lack of suitable substrates currently limits mass production of SiC power devices.