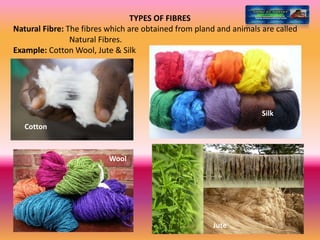

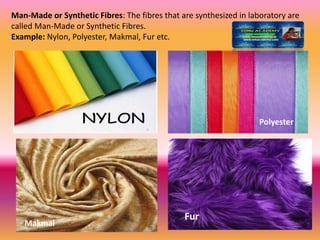

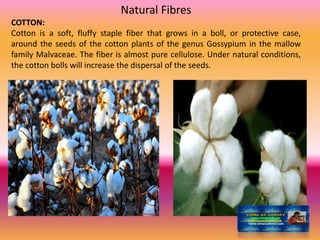

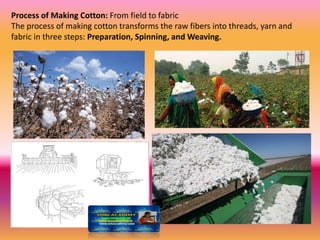

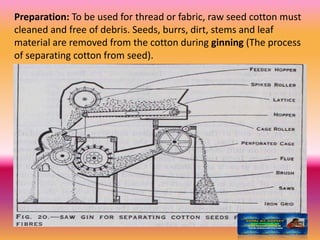

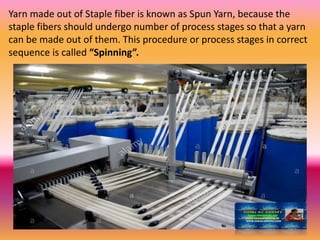

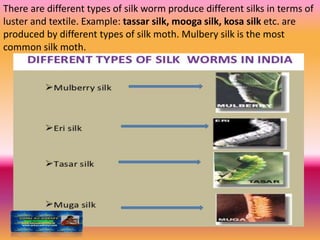

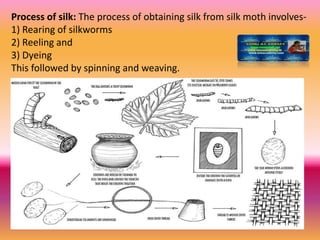

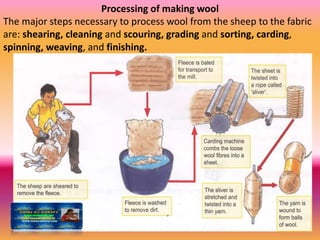

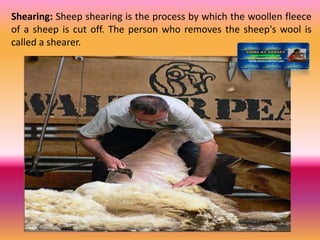

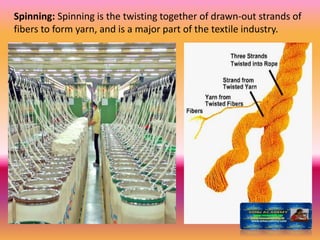

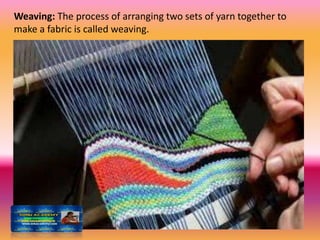

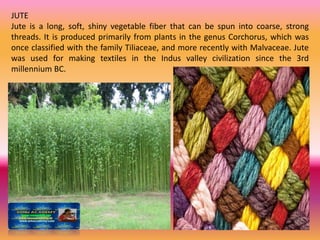

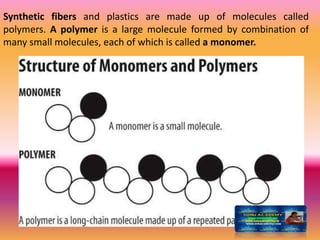

The document outlines the types of fibers used in fabric production, categorizing them into natural fibers (like cotton, wool, and jute) and synthetic fibers (such as nylon and polyester). It explains the processes involved in turning raw materials into clothing, including ginning, spinning, and weaving for natural fibers, and the chemical processing of synthetic fibers. Additionally, it discusses the properties, advantages, and disadvantages of both fiber types.