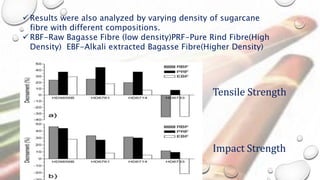

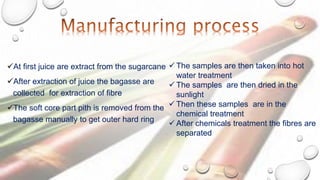

This document discusses sugarcane bagasse fiber, which remains after sugarcane juice extraction. It provides details on bagasse fiber properties like crystallinity, fineness, moisture absorption and elastic recovery. The document also outlines different methods used to extract and process bagasse fiber. It notes that bagasse fiber has various applications including fuel, pulp, plastic, boards and furniture due to its properties like low cost, biodegradability, strength and light weight.