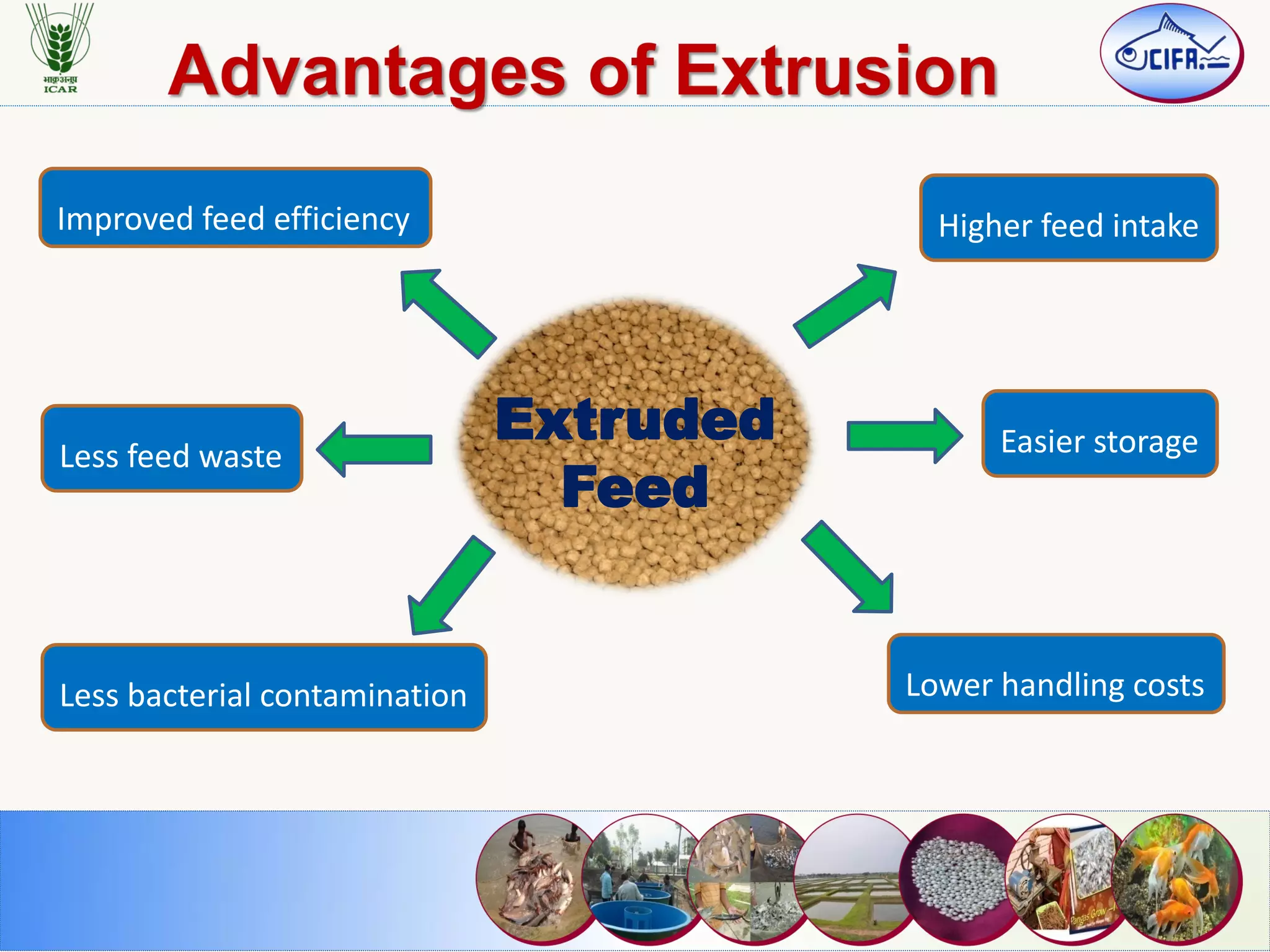

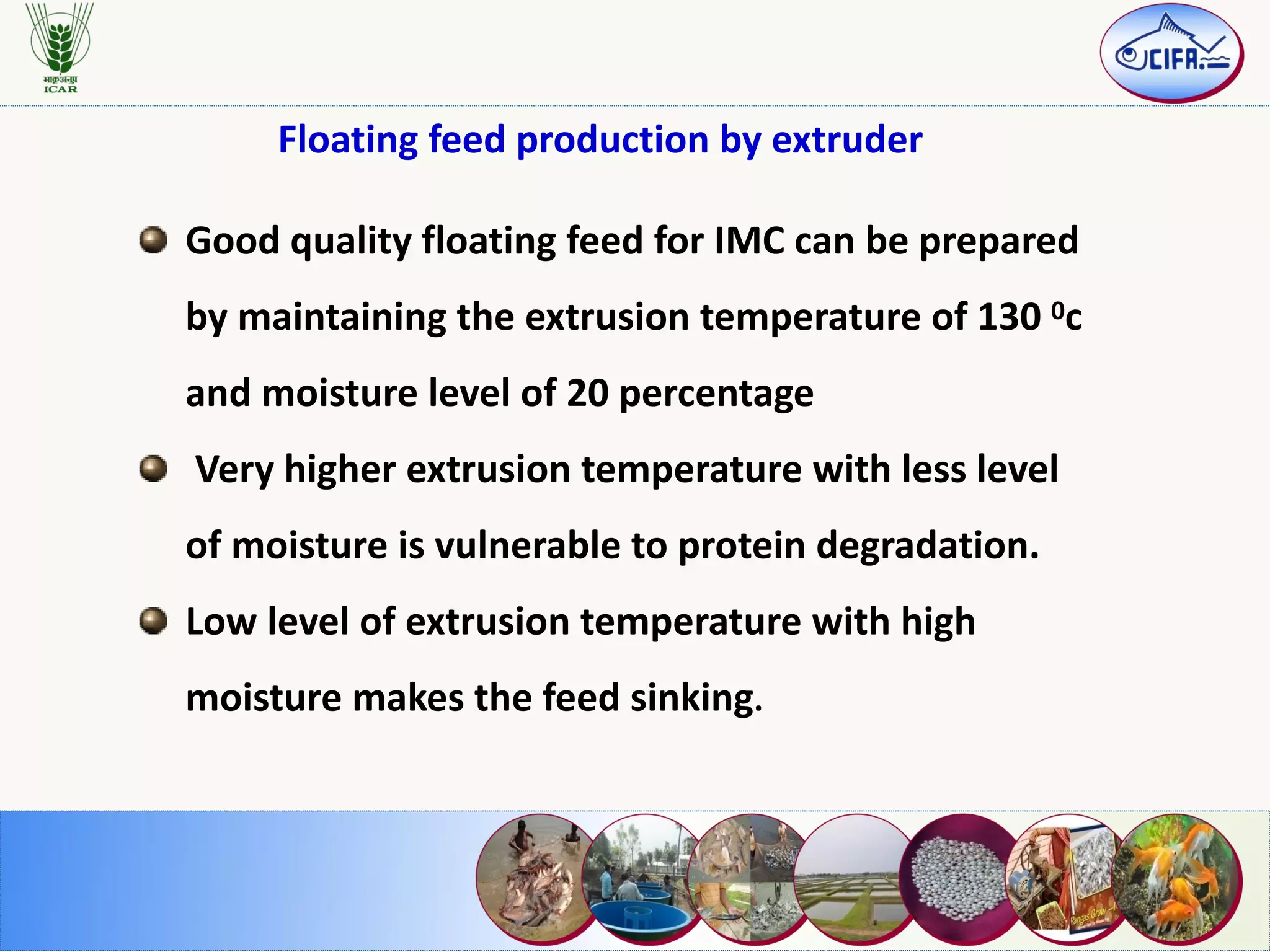

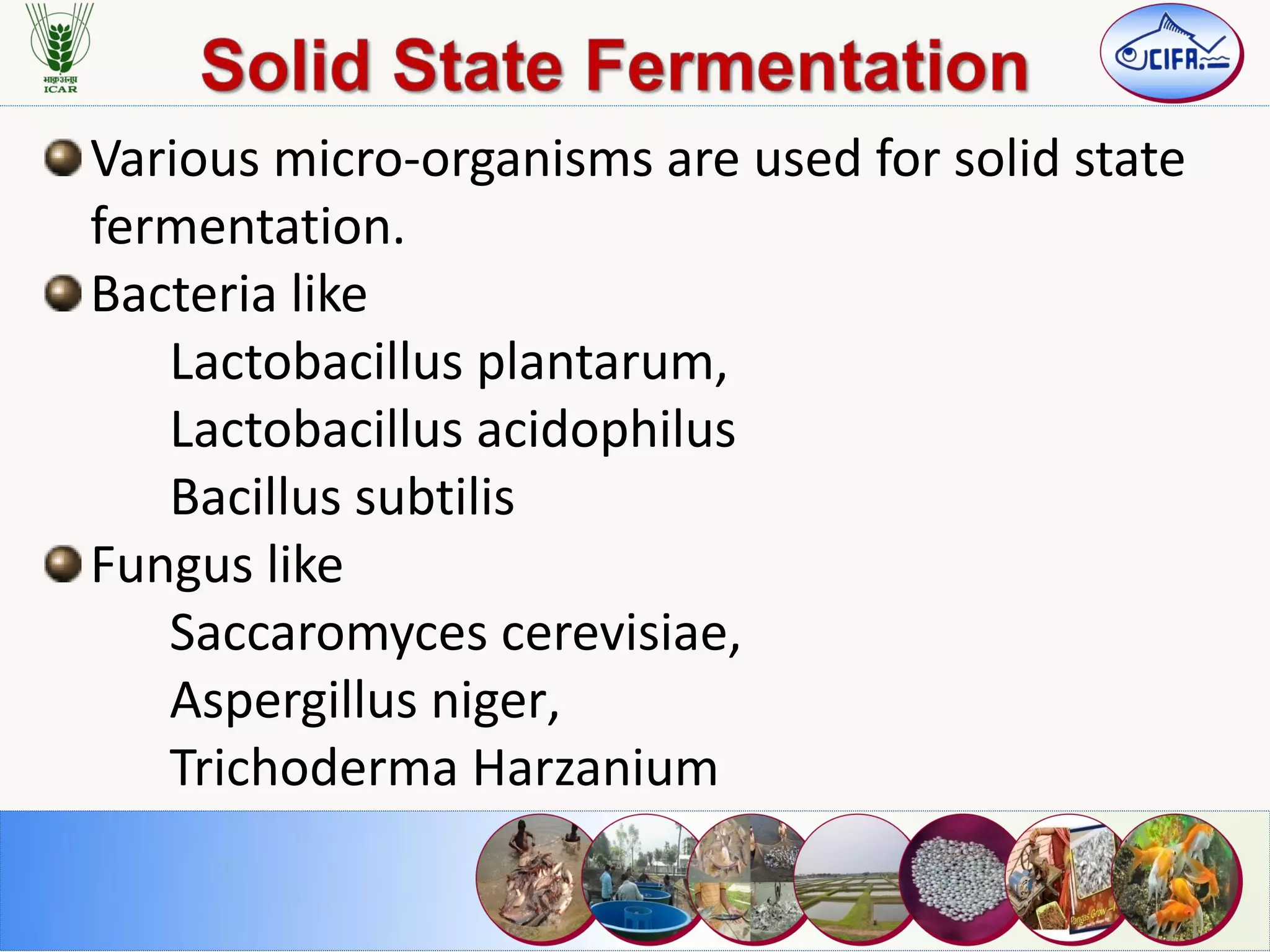

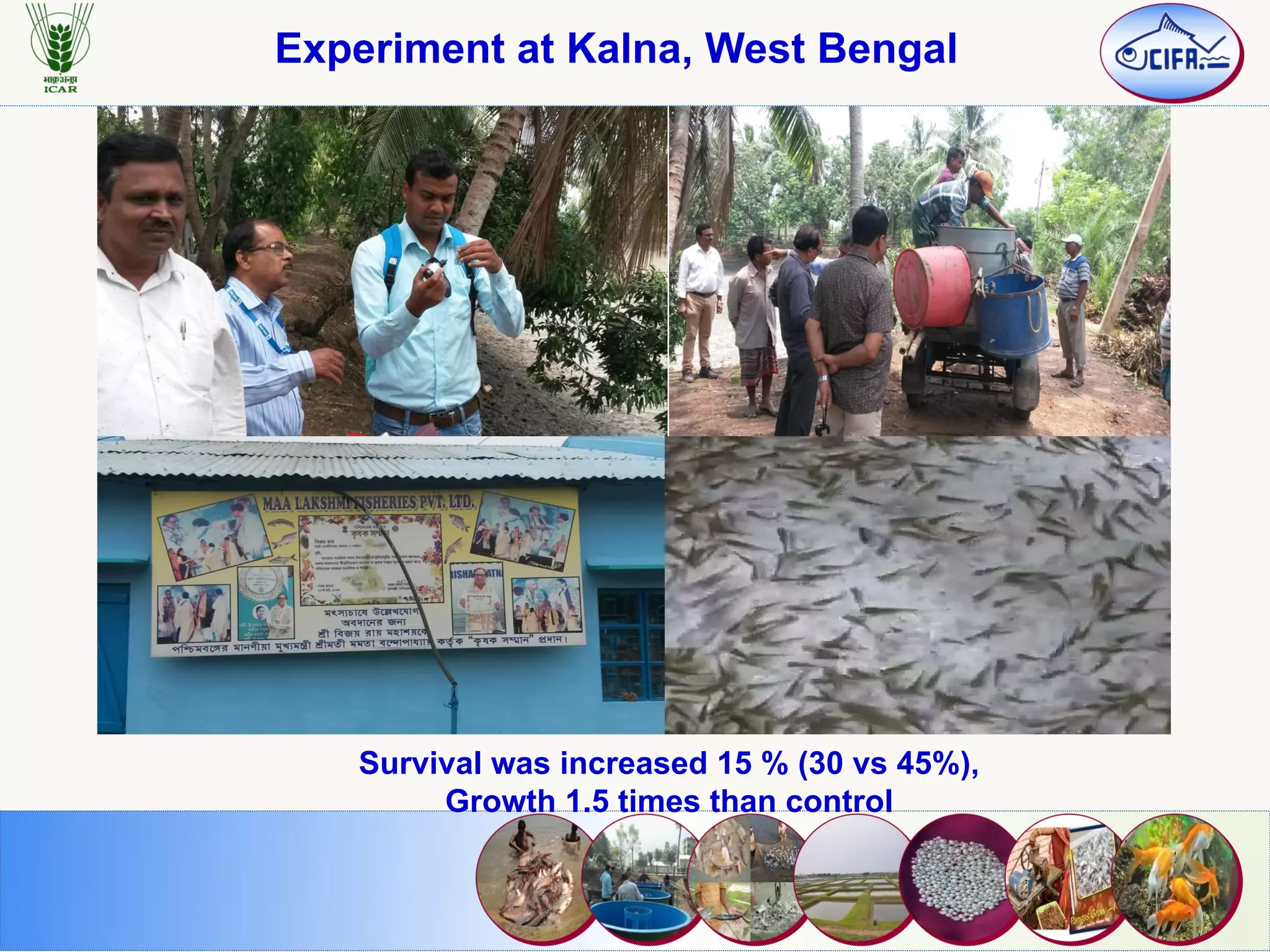

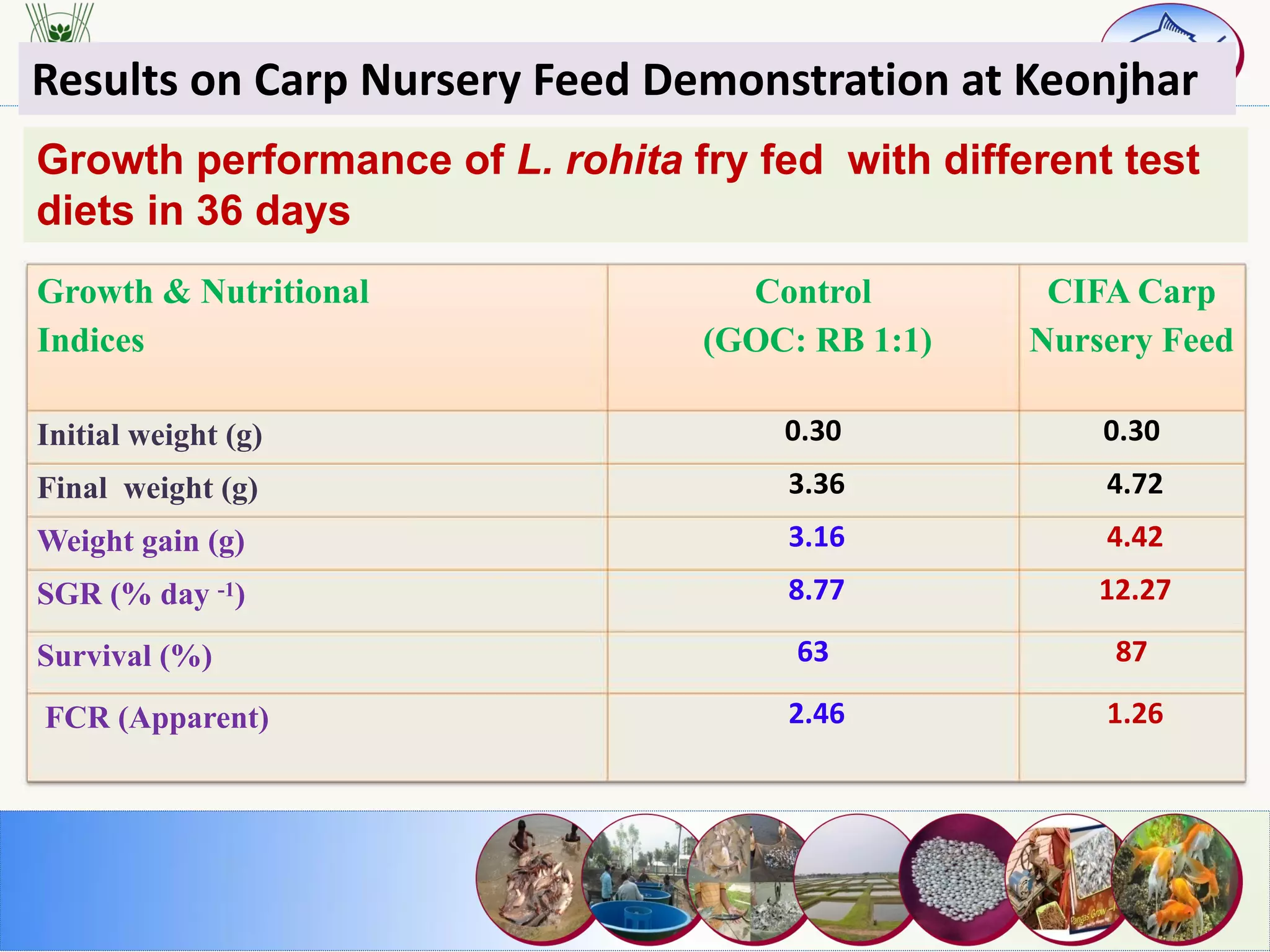

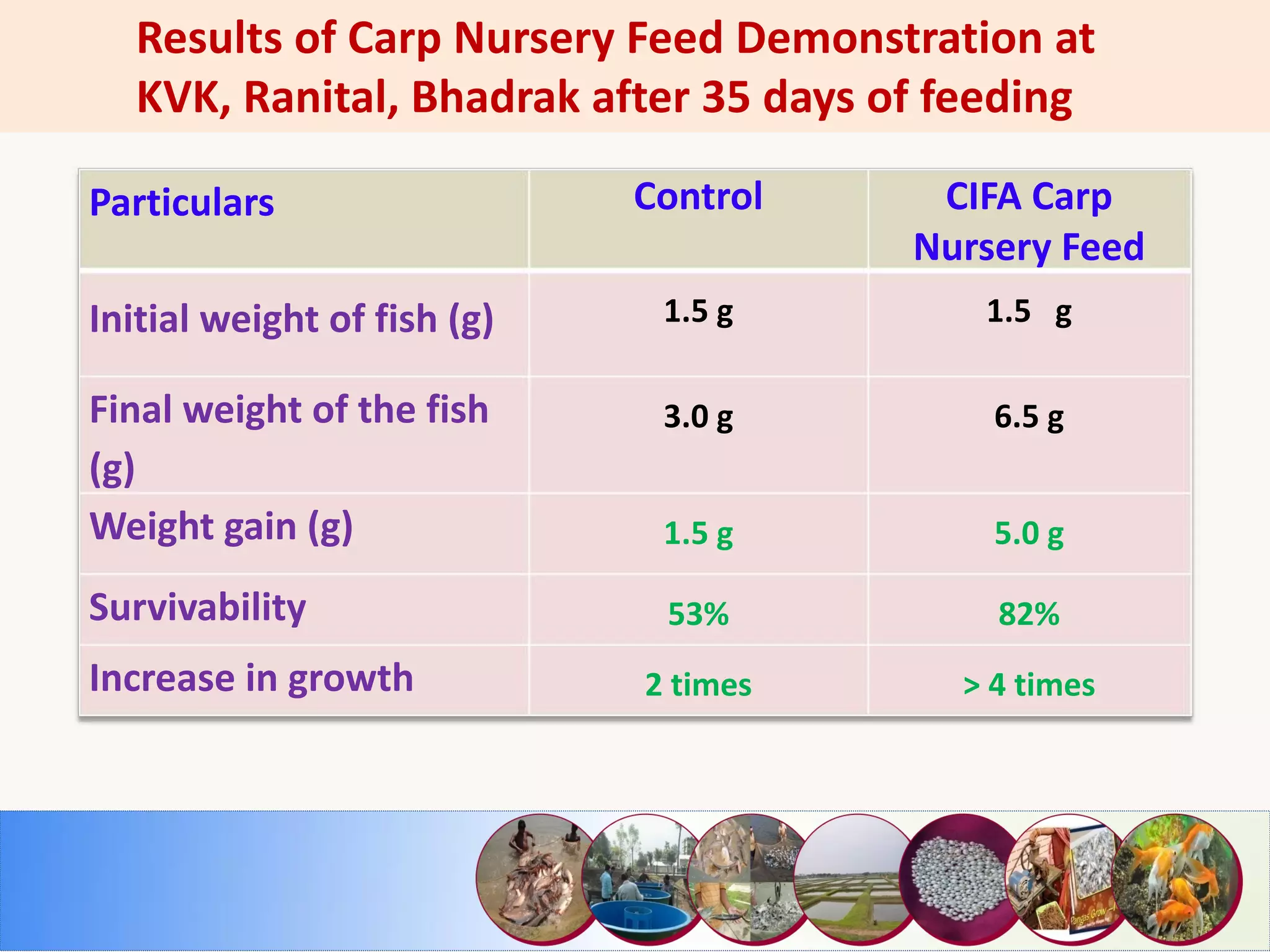

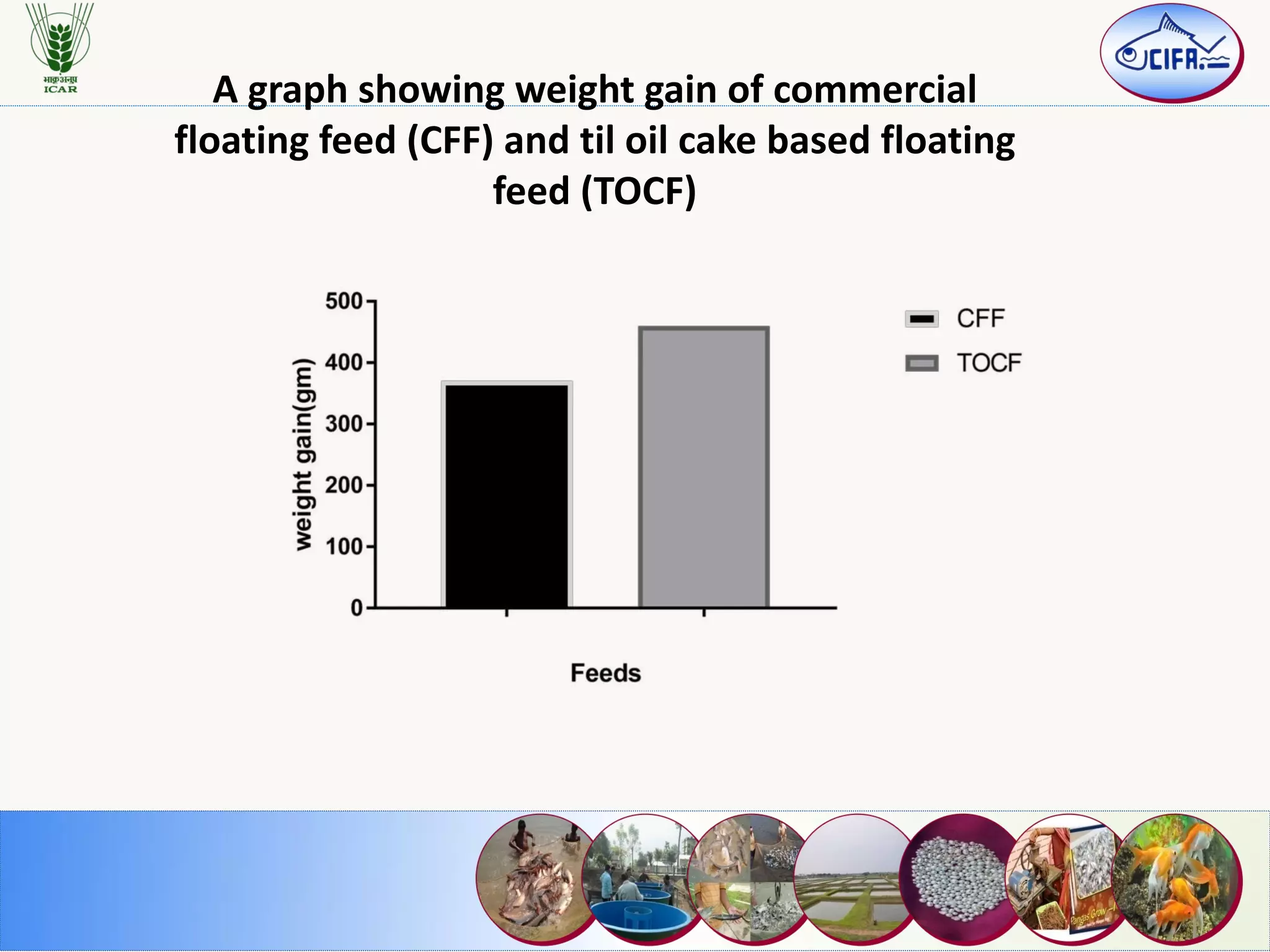

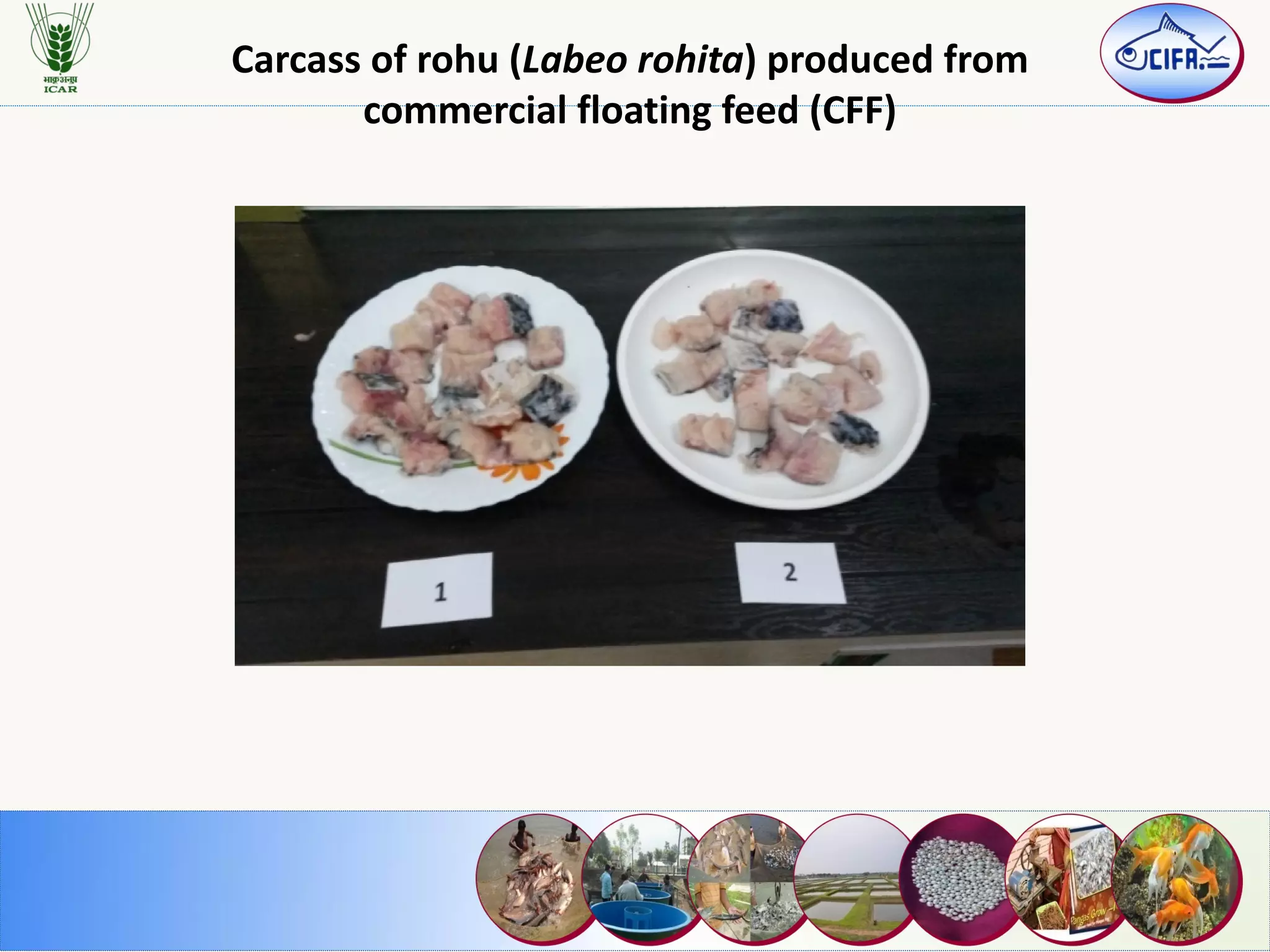

The document summarizes fish feed technology and management for carp nursery ponds. It discusses the growth of aquaculture production in India and the corresponding increase in demand for aqua feeds. Locally available ingredients like rice and wheat bran are commonly used in freshwater aquaculture feeds but have limitations. The ICAR-CIFA has developed extruded floating feeds for carp using local ingredients like til oil cake which have shown improved growth and survival rates in demonstrations and field trials compared to commercial feeds. Extrusion processing, soaking, steaming and fermentation techniques can improve the nutritional quality and digestibility of feeds. The document provides details on the formulation and performance of carp starter and grower feeds developed by ICAR-CI