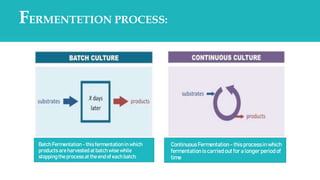

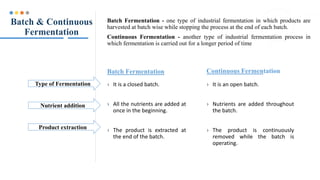

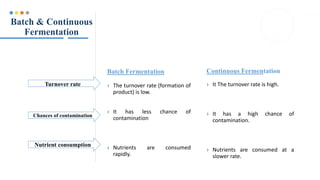

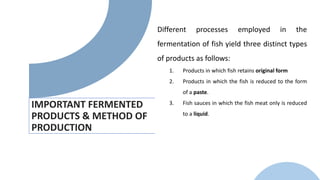

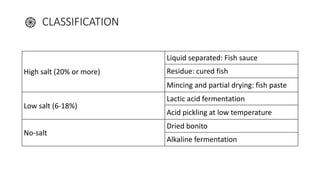

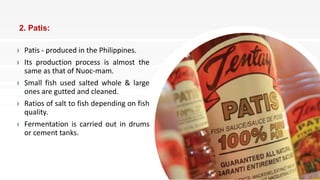

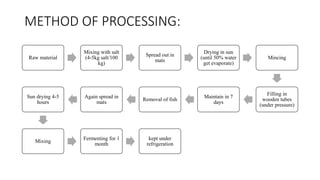

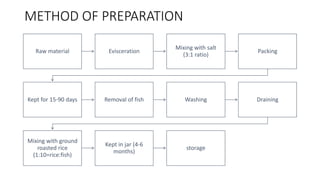

The document provides an overview of fermented fish products, including fermentation processes such as batch and continuous fermentation, and various fermentation methods used in different Asian countries. It discusses important fermented products like fish sauces and fish pastes, along with their production methods and ingredient ratios. Additionally, it covers the importance of microorganism screening, detection assays, fermentation media preparation, and maintenance of stock cultures in the production of these products.