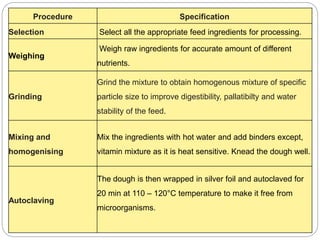

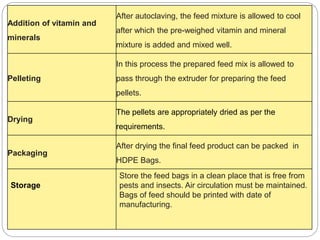

This document discusses feed formulation and processing. Feed formulation involves combining ingredients to meet animal production goals in a balanced, palatable, and stable manner. The formulation process considers available local ingredients, nutrient contents, animal requirements, and physical limitations. Feed processing alters ingredients physically and sometimes chemically to improve utilization, mixing, and stability. Key processing steps include weighing, grinding, mixing, autoclaving, pelletizing, drying, packaging, and storage. The overall goal is to produce a cost-effective feed that meets regional animal nutritional needs.