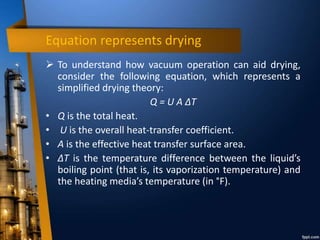

The document discusses vacuum ovens, which are used to dry materials through the application of heat under reduced pressure. Vacuum ovens work by heating shelves inside a vacuum chamber to indirectly apply heat to trays of product. This allows water to evaporate off the product at a lower temperature than normal due to the reduced boiling point under vacuum. Key advantages are lower energy use and avoiding damage to heat-sensitive materials compared to normal drying. Pharmaceutical, plastic, and food industries commonly use vacuum ovens in processing.