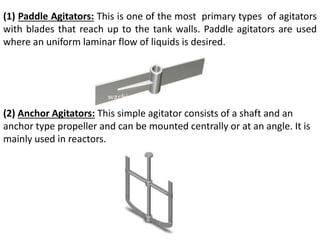

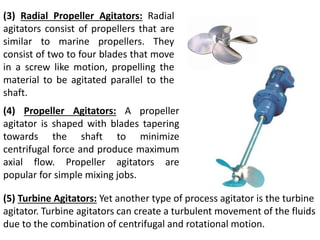

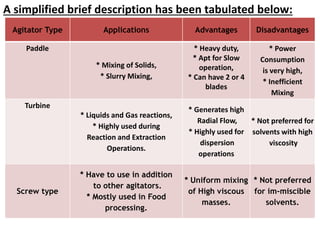

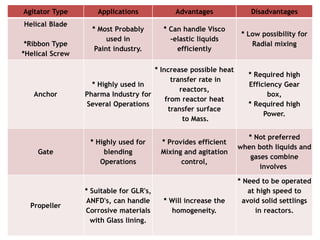

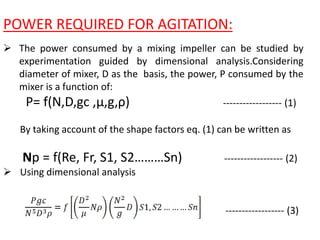

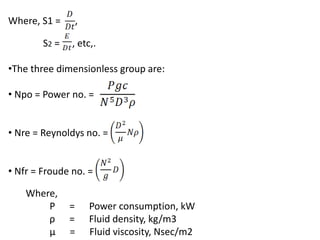

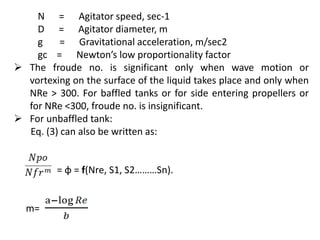

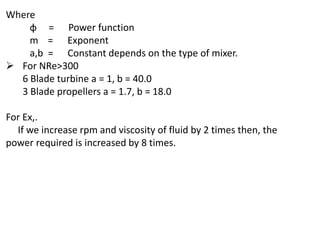

This document discusses different types of agitators used in pharmaceutical industries and the factors considered in their selection. The main types described are paddle, anchor, radial propeller, propeller, turbine, and helical agitators. Selection depends on viscosity of the fluid and whether mixing time or power consumption is more important. Power required for agitation can be estimated using dimensionless numbers accounting for properties like density, viscosity, agitator speed and diameter.