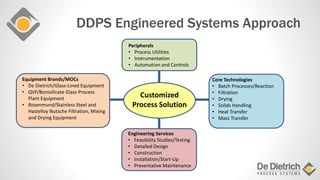

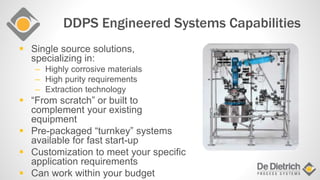

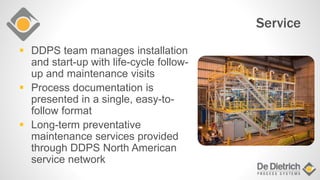

DDPS provides customized engineered systems for processes requiring high purity or handling corrosive materials. They offer a full range of engineering services from feasibility studies to installation and maintenance. Their systems include modular equipment, quality assurance testing, and can be tailored for various applications in industries such as pharmaceuticals, chemicals, and semiconductors. DDPS designs and builds complete turnkey systems or can supplement existing equipment.