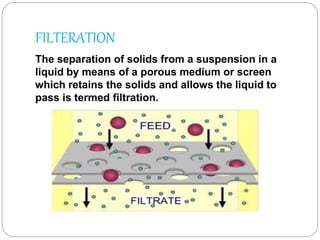

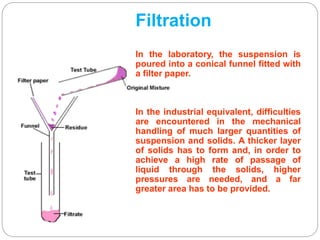

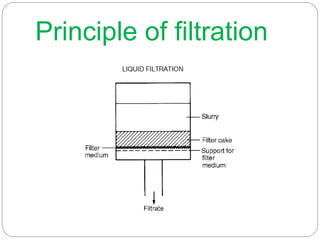

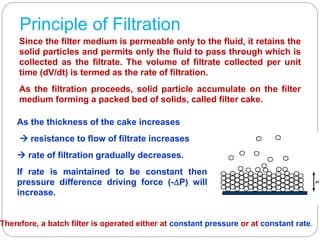

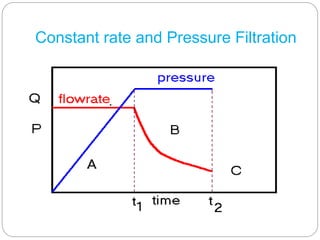

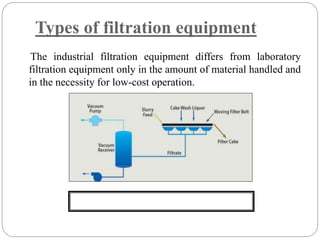

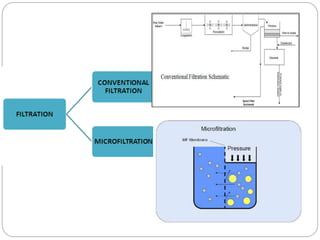

Filtration is a mechanical process used to separate solids from liquids by using a permeable medium, with the liquid that passes through being termed the filtrate. Various types of filtration methods and equipment exist, including batch and continuous filters, which are utilized across industries for liquid clarification and solid removal. Applications of filtration range from household uses, like coffee filters, to industrial processes in water treatment, pharmaceuticals, and environmental pollution control.