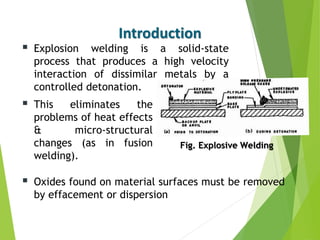

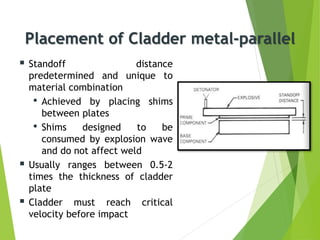

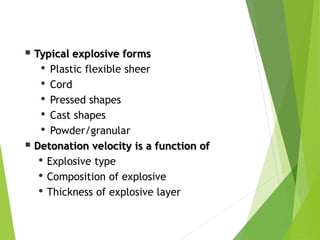

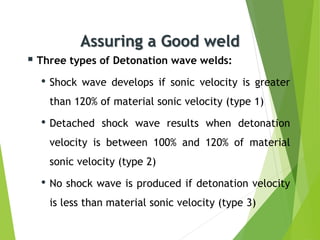

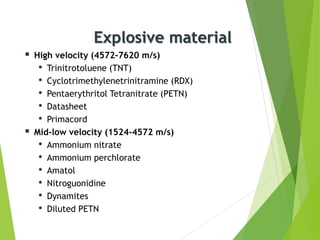

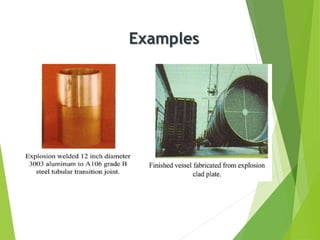

Explosive welding is a solid-state process that joins dissimilar metals through high-velocity impact using controlled explosions. It produces strong welds without heat effects or microstructural changes common in other welding methods. The explosive material is placed between the metals to be joined and detonated, driving one metal into the other at velocities over 4500 m/s to form a metallurgical bond. Explosive welding can join materials like aluminum to steel that are difficult to weld through other methods. It has applications in industries like petroleum refining, shipbuilding, and aerospace for cladding, sealing, and repairing parts.