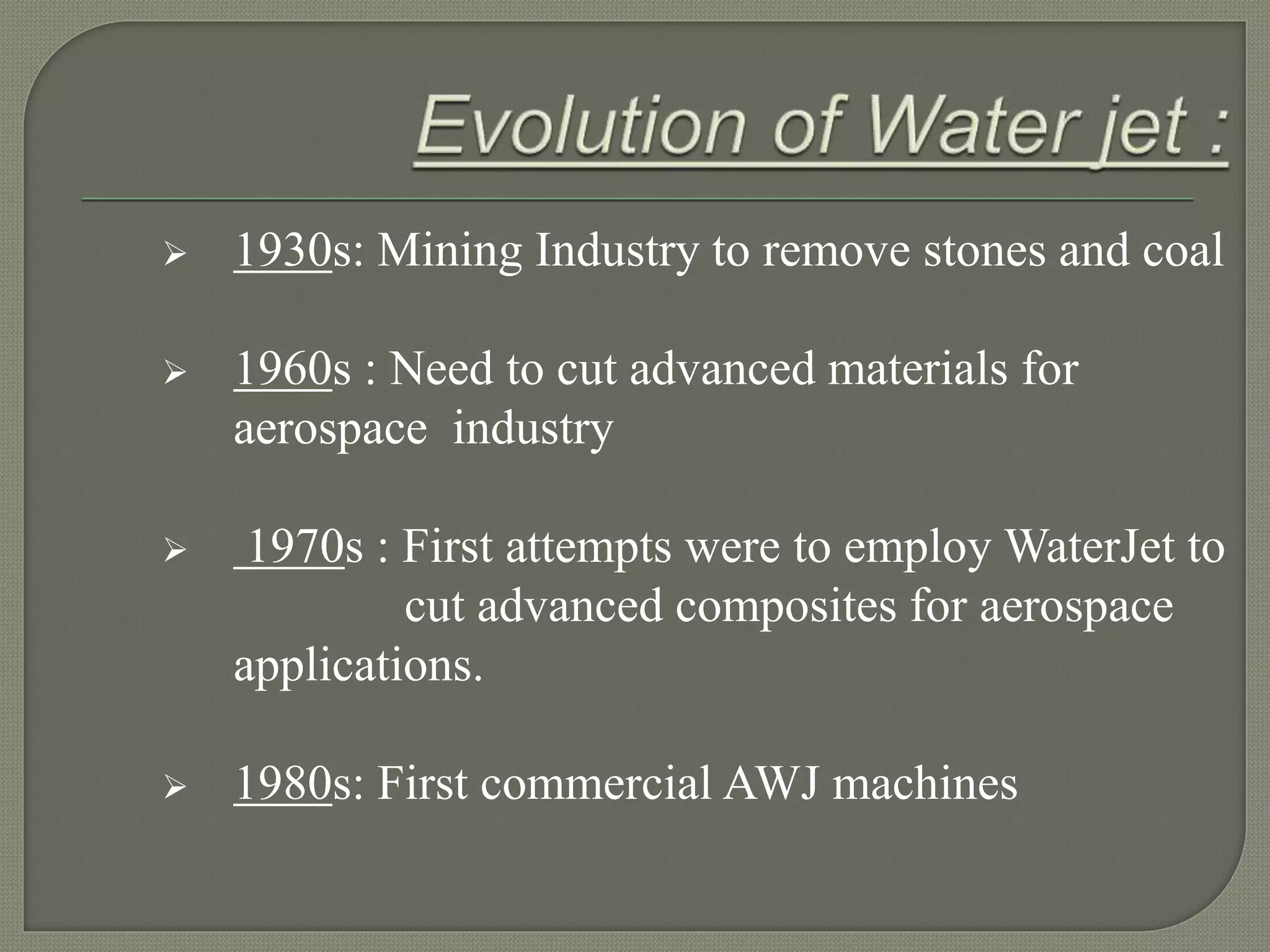

This presentation discusses waterjet machining. It is a versatile machining process that uses high-pressure water or water mixed with abrasives to cut materials. Waterjet machining is useful for both soft materials cut with plain water jets and hard materials cut with abrasive water jets. It has advantages over other cutting techniques in that it produces no heat affected zone, can cut a wide range of materials, and is environmentally friendly. The presentation provides details on the history, mechanisms, applications and capabilities of waterjet machining.