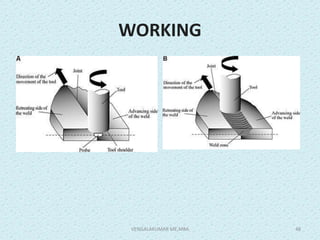

This document discusses various solid-state welding processes including cold welding, diffusion bonding, explosive welding, hot pressure welding, roll welding, ultrasonic welding, and friction stir welding. Each process is characterized by its methods, applications, advantages, and disadvantages, highlighting their use in industries such as aerospace, automotive, and nuclear. The document emphasizes the differing techniques and applications associated with each welding type while outlining the conditions necessary for successful welding.