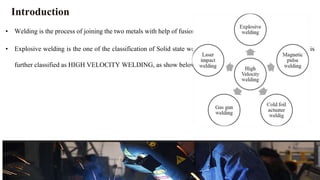

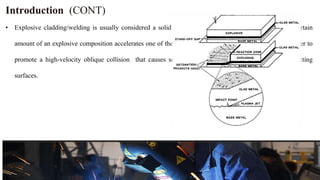

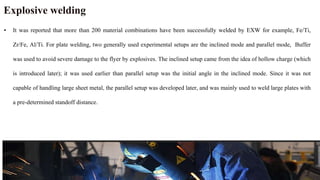

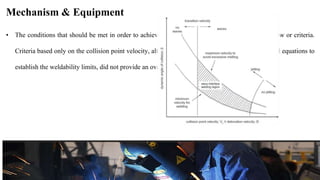

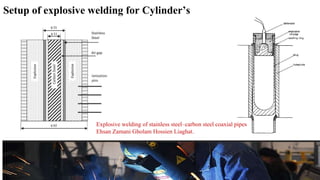

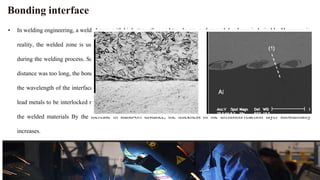

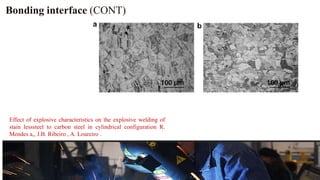

This document provides an overview of explosive welding on concentric cylinders. It discusses the explosive welding process, bonding interface, solidification at the weld zone, and applications. Explosive welding uses detonation of an explosive to accelerate one material into another, causing plastic deformation and bonding without melting. It can join many dissimilar metals and produces a weld joint stronger than the base metals. However, it is limited to simple geometries like flat or cylindrical surfaces. Applications include heat exchangers, pressure vessels, and repair of heat exchanger tubes.