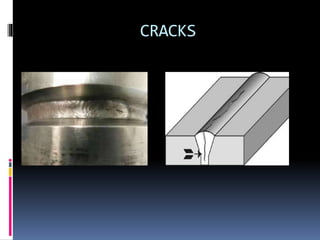

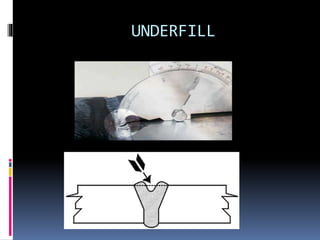

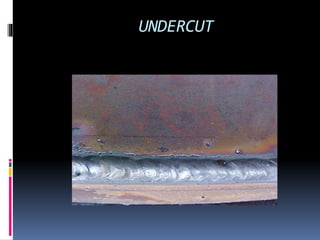

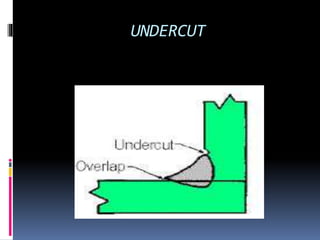

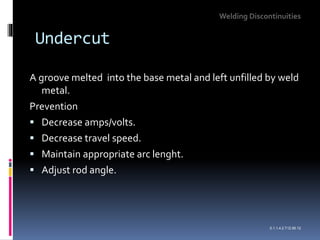

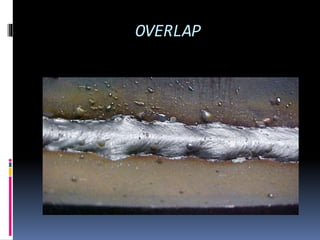

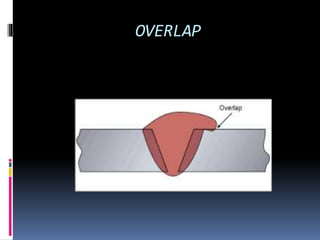

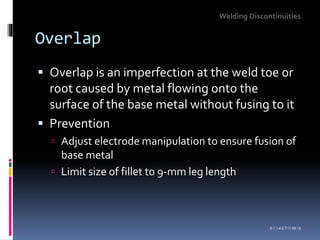

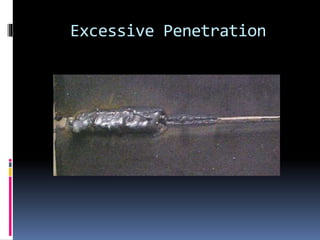

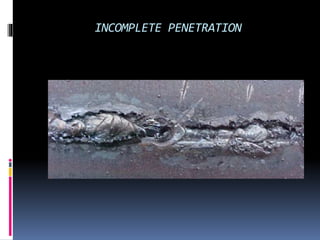

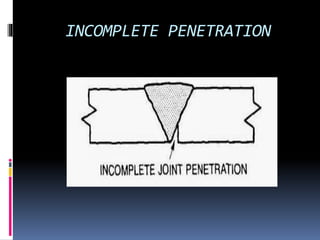

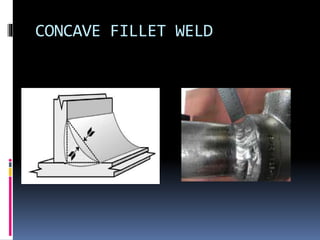

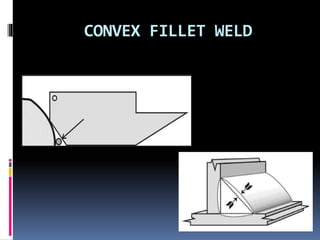

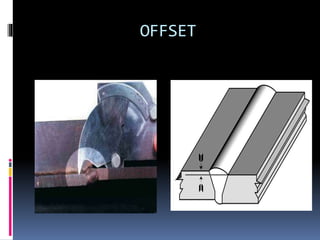

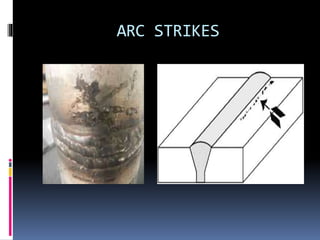

This document discusses various welding defects and how to prevent them. It identifies the most common defects such as cracks, underfill, porosity, undercut, overlap, incomplete fusion, spatter, excessive penetration, incomplete root penetration, concave/convex fillet welds, offset, slag inclusions, and arc strikes. For each defect, it provides a definition and recommendations on how to avoid the defect through proper joint preparation, parameter adjustment, technique, cleaning, and equipment maintenance. The overall objective is to avoid defects through correct design, tools, procedures and operator training in order to improve productivity and reduce costs.