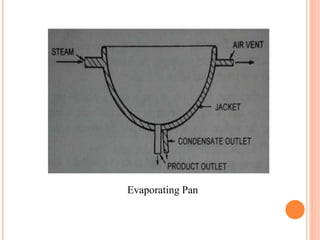

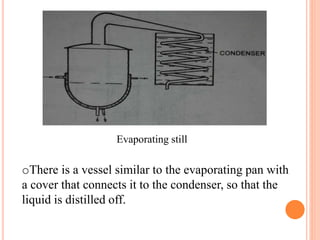

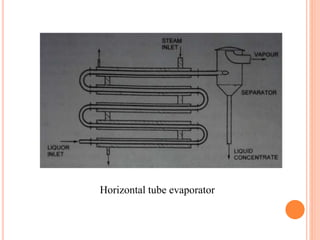

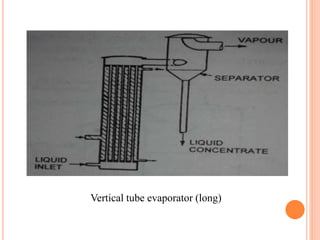

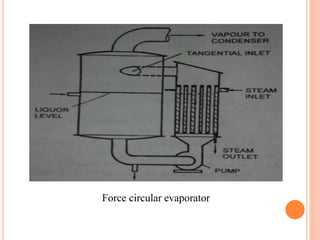

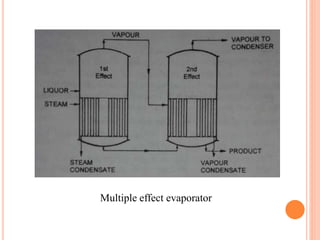

Evaporation is the vaporization of a liquid below its boiling point, caused by exposure to heat or reduction of pressure. Several factors affect the rate of evaporation, including temperature, surface area, agitation, and atmospheric conditions. There are various types of evaporators used in pharmaceutical manufacturing, including evaporating pans, evaporating stills, horizontal tube evaporators, vertical tube evaporators, forced circular evaporators, and multiple effect evaporators. Selection depends on the type of product required and economic considerations.