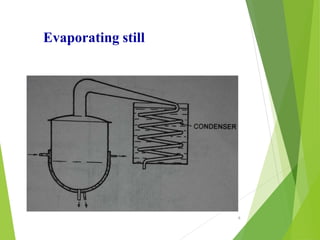

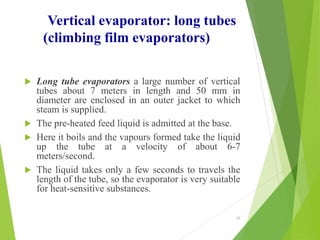

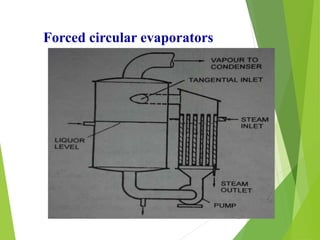

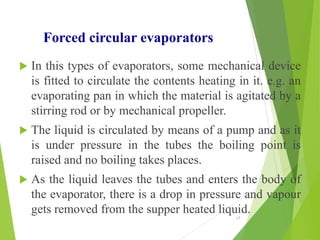

The document discusses the process of evaporation, its applications in manufacturing bulk drugs and biological products, and the factors influencing evaporation. It classifies evaporation equipment into categories such as natural circulation, forced circulation, and film evaporators, detailing their designs and functionalities. Additionally, it addresses challenges encountered with evaporator accessories and highlights the importance of temperature and vapor pressure in the evaporation process.