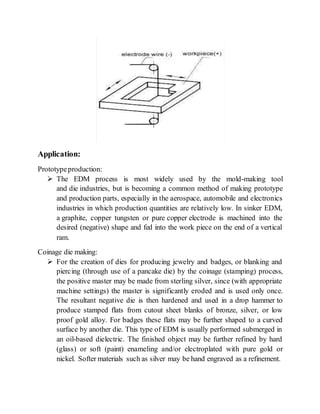

EDM works by using electrical discharges (sparks) to erode away unwanted material from a workpiece to create a desired shape. A CNC wire cut EDM machine controls the gap between an electrode wire and workpiece to cause precise electrical discharges in insulating liquid. These discharges vaporize small amounts of material from the workpiece surface, gradually forming the final shape. EDM is commonly used for mold making, prototype production in industries like aerospace and electronics, and for creating coinage dies due to its ability to accurately machine hard metals and intricate details.