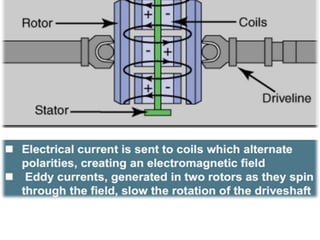

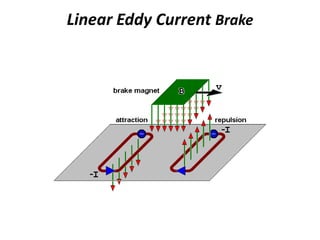

This document provides an overview of eddy current braking. It begins by explaining the principles of induction and Lenz's law. It then describes how eddy current brakes work by creating eddy currents in a conductor through a varying magnetic field, generating resistance and an opposing magnetic field for braking. The document discusses the construction and working of both circular and linear eddy current brakes. It notes advantages like contactless braking and adjustability, and disadvantages like diminished braking at low speeds. Applications mentioned include trains, rollercoasters, and spacecraft vibration elimination. The document concludes by arguing eddy current brakes could replace ordinary brakes by providing contactless, high-force braking.