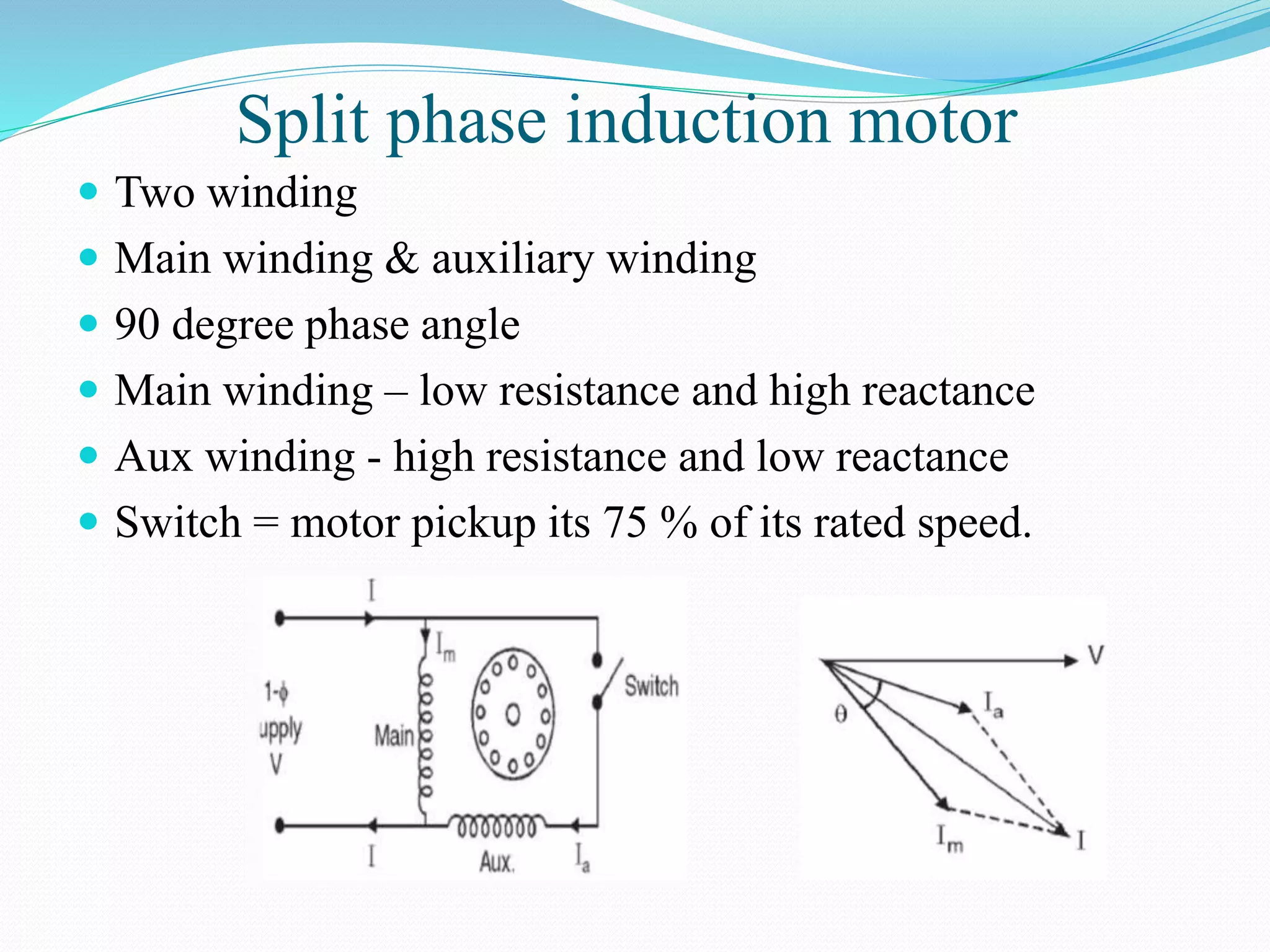

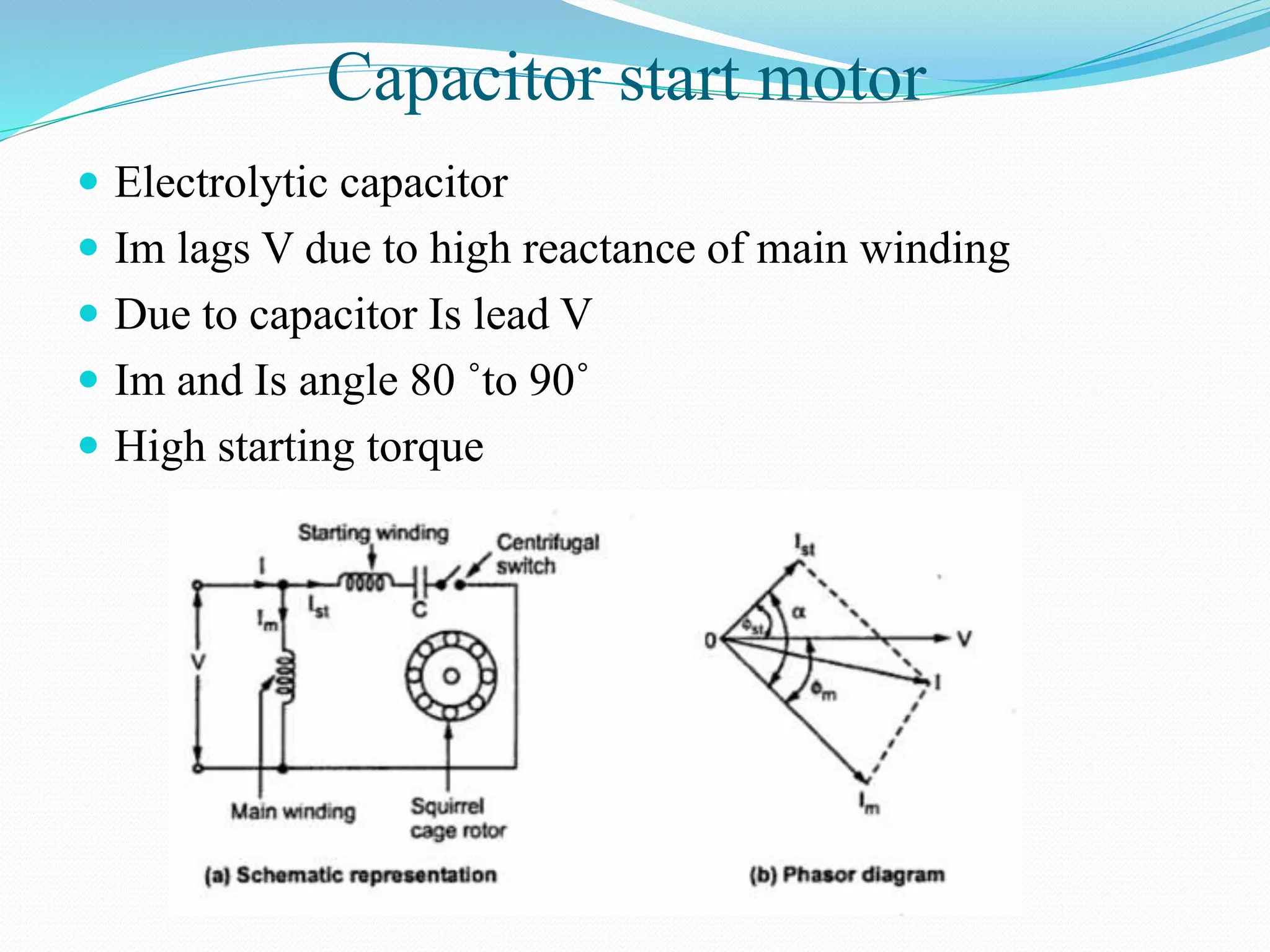

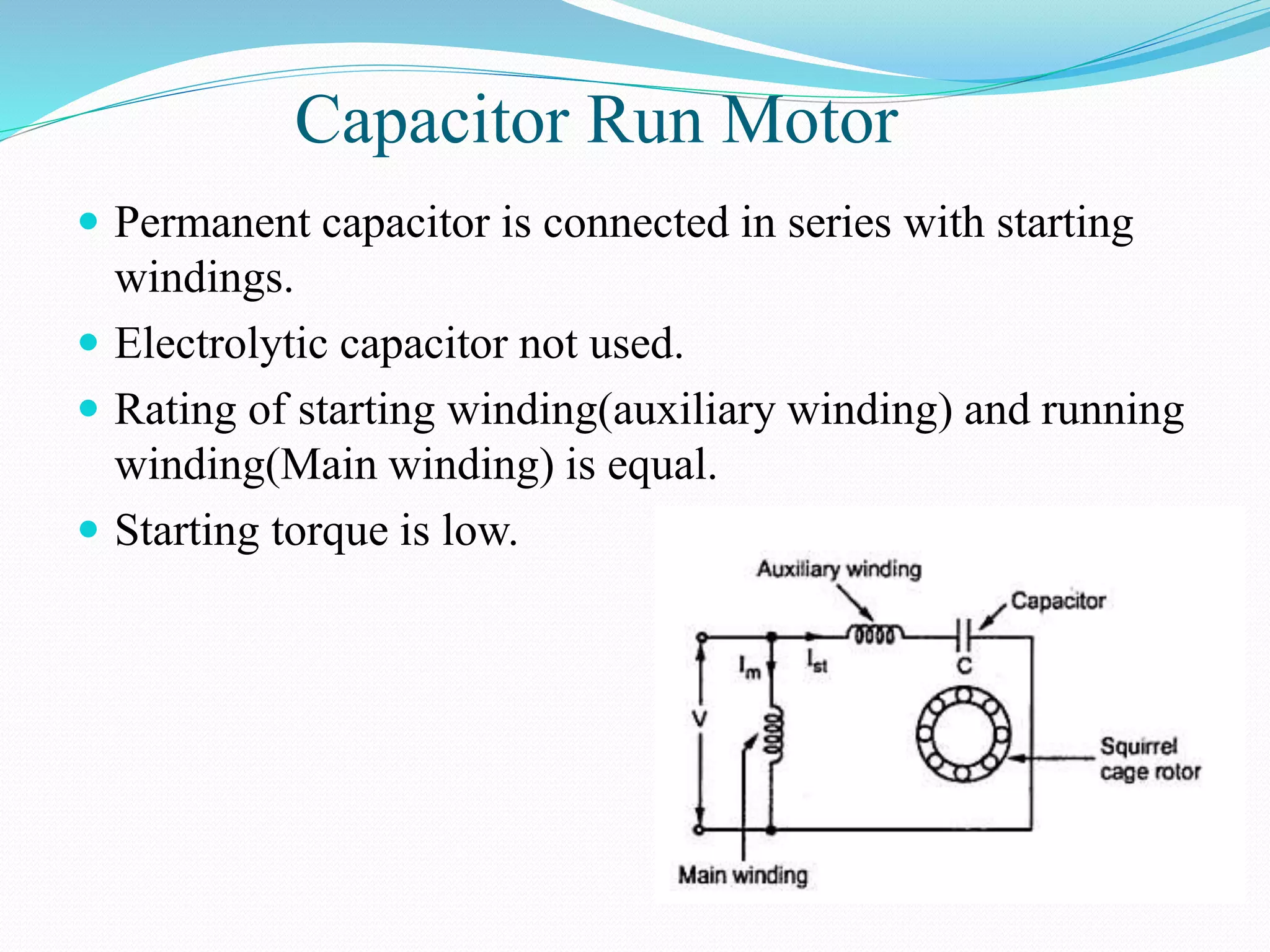

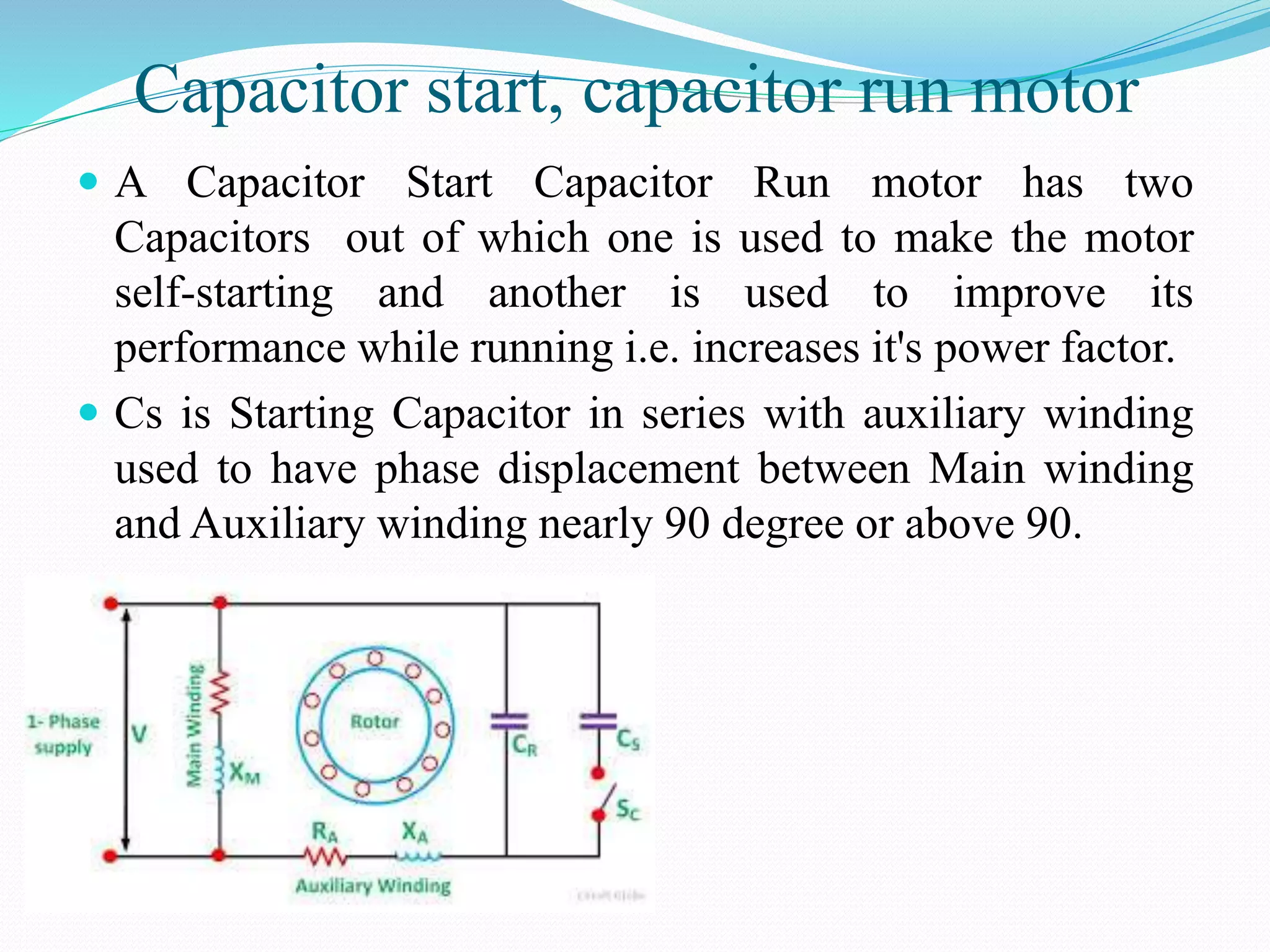

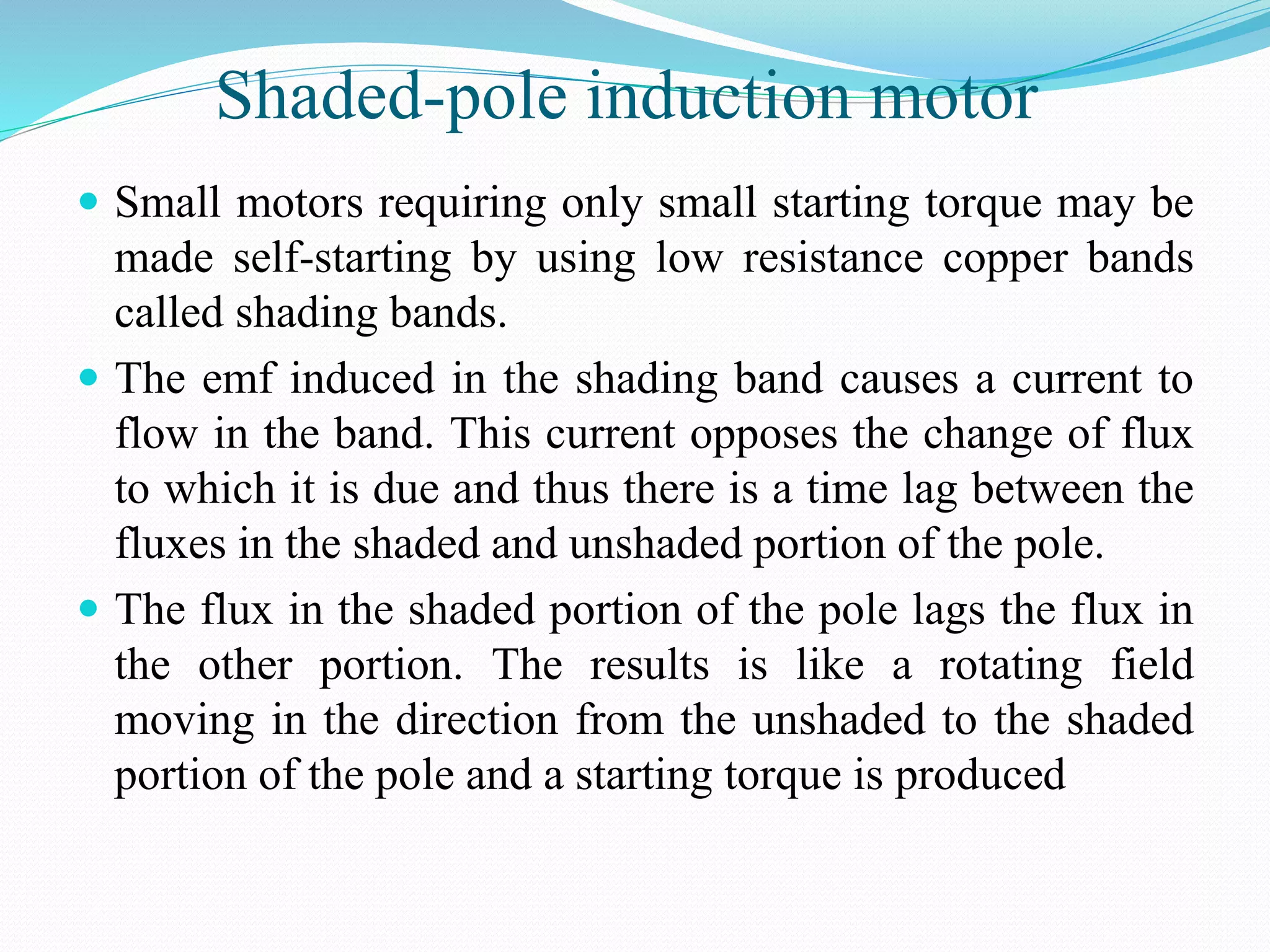

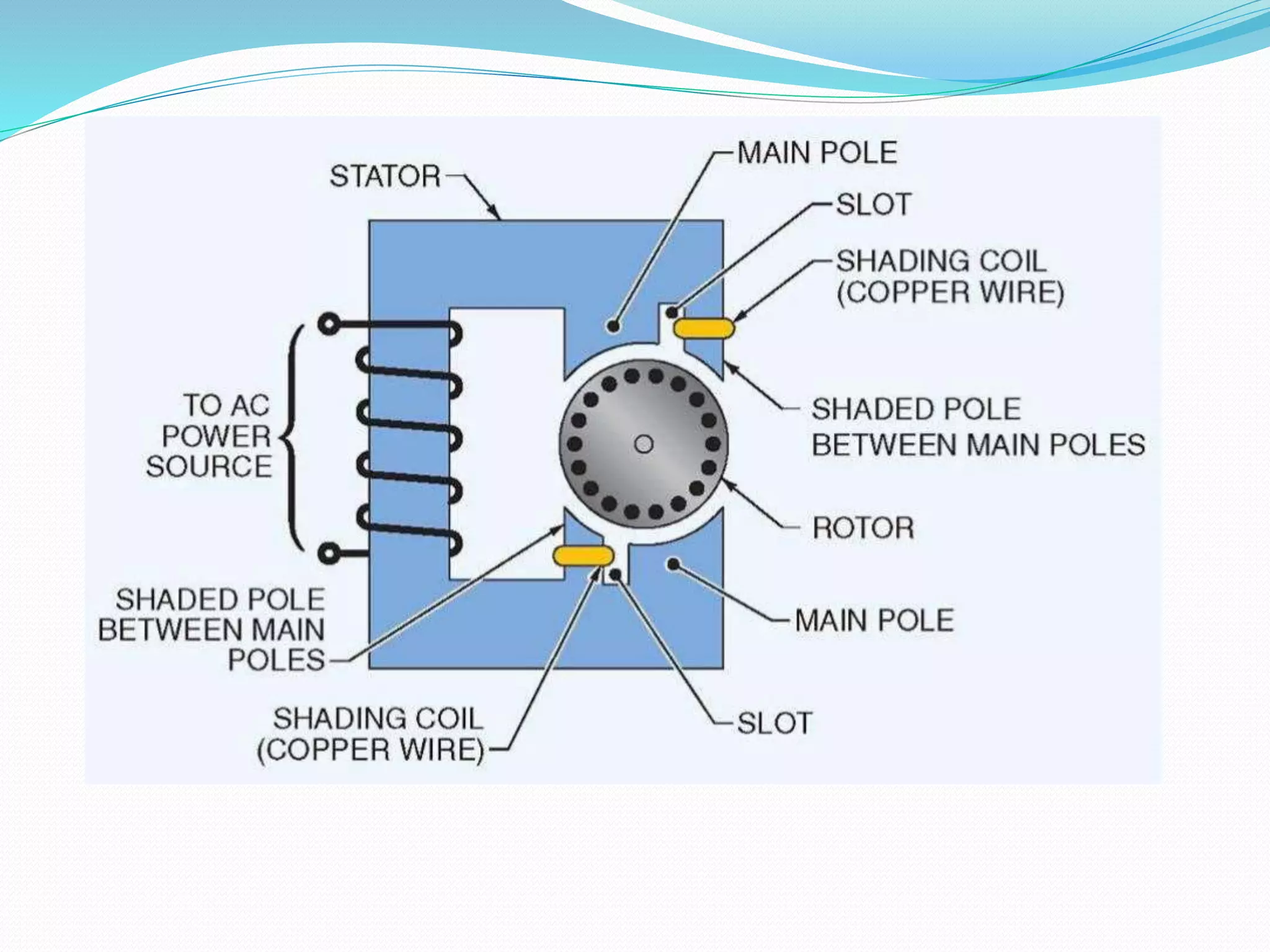

This document discusses different types of single-phase induction motors, including their operating principles, starting methods, and characteristics. It describes split-phase, capacitor-start, capacitor-run, and capacitor-start/capacitor-run induction motors. It also discusses shaded-pole induction motors and their applications in small, low-power devices.