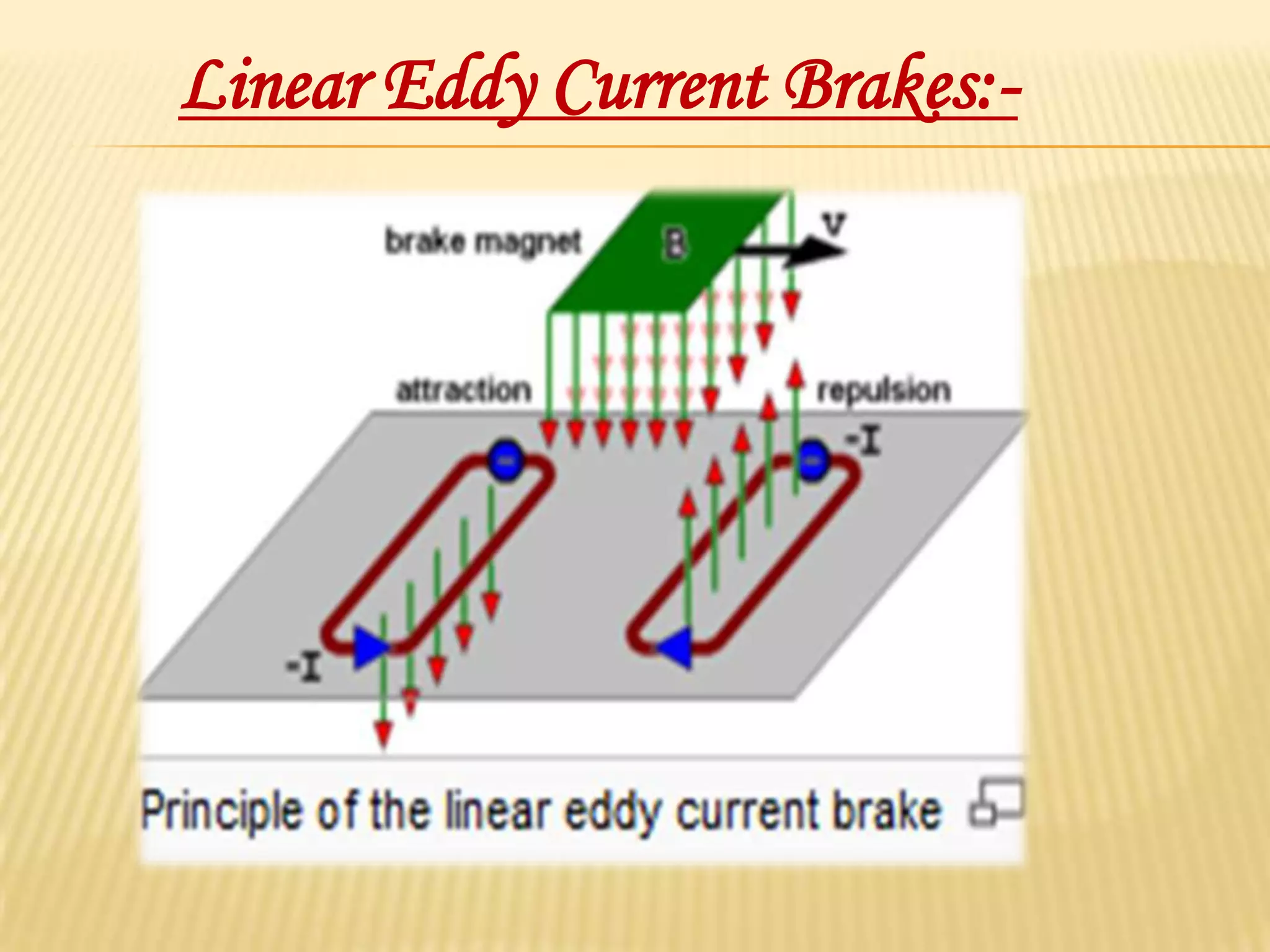

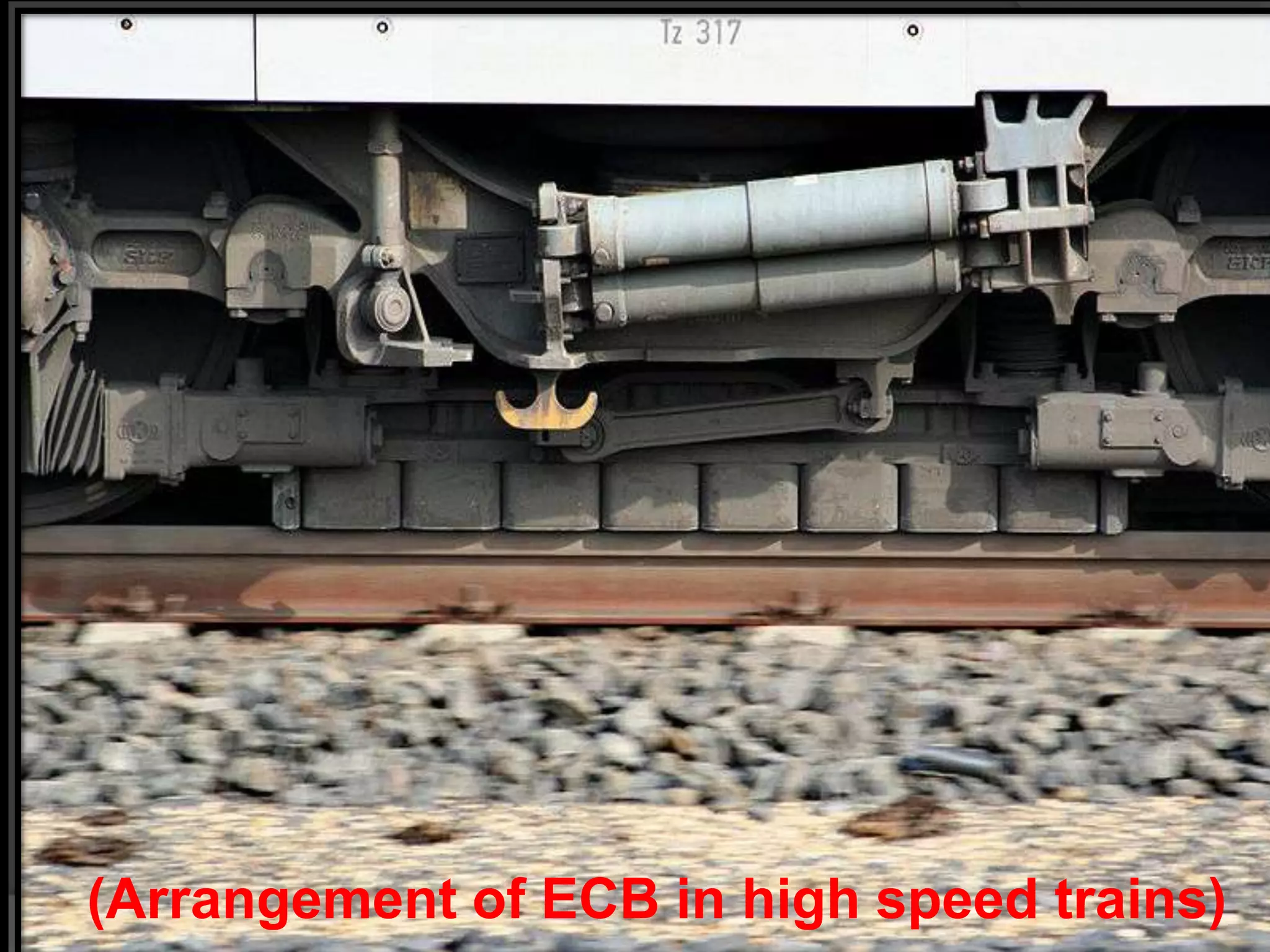

Eddy current brakes use magnetic fields to induce currents in conductors that generate their own magnetic field opposing the original field, slowing rotation or movement. They have electromagnets that create magnetic fields to induce currents in discs or rails, generating braking force without contact. Eddy current brakes are quiet, frictionless, and low maintenance, making them useful for trains and other vehicles.