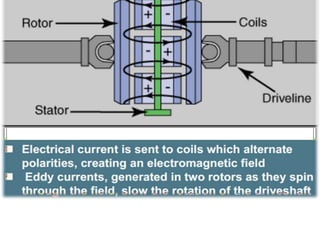

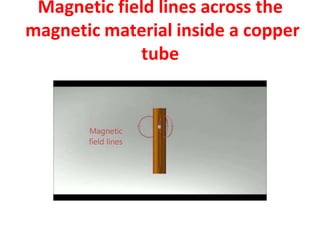

Eddy current brakes work by generating eddy currents in a conductive material using a changing magnetic field from electromagnets. These eddy currents then generate their own magnetic field that opposes the original field due to Lenz's law, creating drag and slowing the object. There are circular and linear eddy current brake configurations. Advantages include being contactless with no wear, adjustable braking force, and effectiveness even at high speeds. Applications include train braking and roller coasters. Future developments could replace ordinary brakes and control high speed trains solely with eddy current brakes.