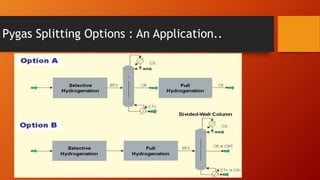

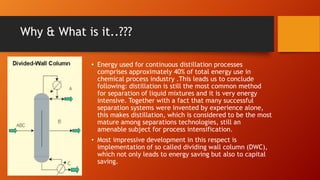

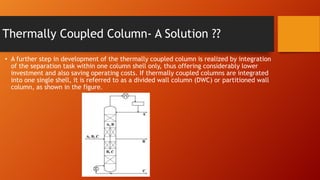

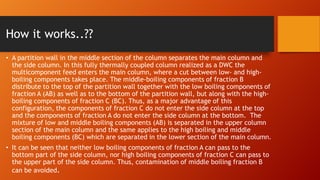

Divided wall distillation columns allow for the separation of liquid mixtures into three fractions using a single distillation column. This technique saves both capital and operating costs compared to conventional arrangements using multiple distillation columns. A divided wall column works by installing a partition wall that separates the single column into two distillation columns that can operate in a thermally coupled manner. Various parameters of divided wall columns like reflux ratio, feed stage location, and dynamic response can be optimized to improve separation efficiency and reduce energy usage.

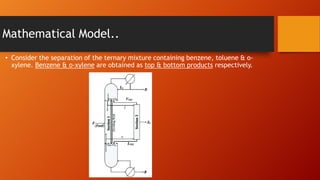

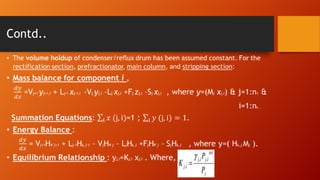

=V1 y1,i(2)+ V1 y1,i(3).

1

1

1

Liquid Splitting: L0(2)=Ln (1) , L0=[(1-)Ln ](1) ,

where =Liquid Splitting factor.

x0,i(2)=xn1,i(1) , x0,i(3)=xn ,i(1).

1

1

1](https://image.slidesharecdn.com/dividedwalldistillationcolumn-completed1-140105081944-phpapp02/85/Divided-Wall-Distillation-Column-13-320.jpg)