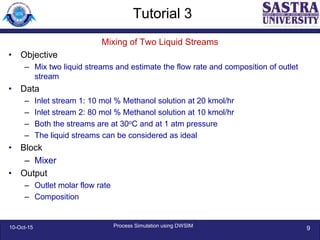

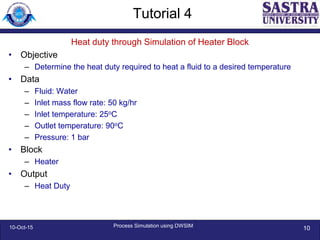

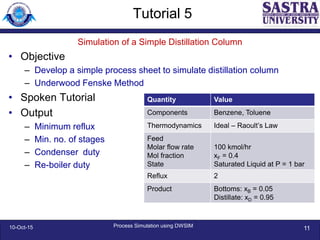

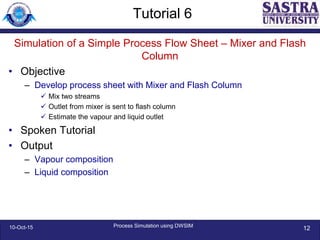

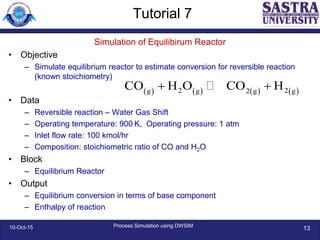

The document discusses using the open source process simulation software DWSIM. It outlines several tutorials that demonstrate how to use DWSIM to simulate common unit operations and develop simple process flowsheets. The tutorials cover creating material streams, generating vapor-liquid equilibrium data, simulating mixers, heaters, distillation columns, and equilibrium reactors. The goal is to complement the learning process through hands-on simulation of different process scenarios using the free and effective DWSIM software.