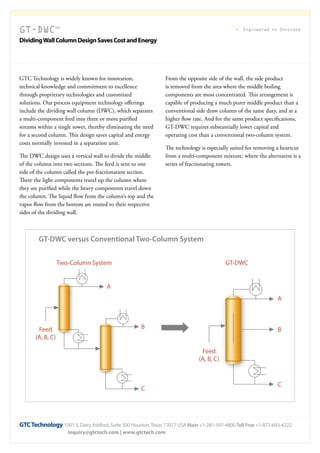

GTC Technology offers a dividing wall column (DWC) design that separates a multi-component feed into three or more purified streams within a single tower, eliminating the need for a second column. This saves both capital and energy costs compared to a conventional two-column system. The DWC uses a vertical wall to divide the column into two sections for pre-fractionation, allowing light components to travel up and heavy components to travel down while separating out a middle product. GTC provides detailed engineering and construction management for DWC applications, with estimated 20-30% lower capital and operating costs than a conventional system.