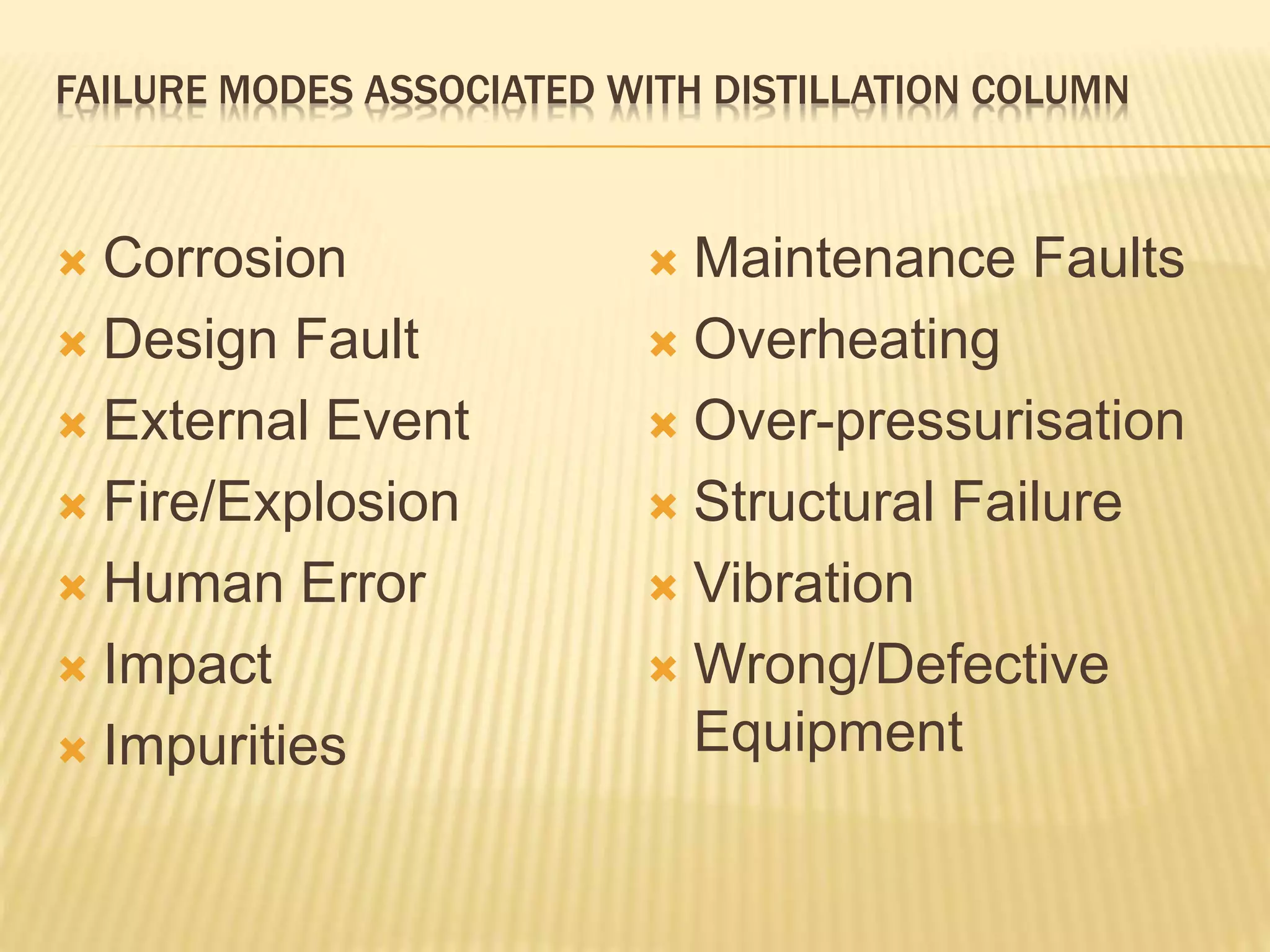

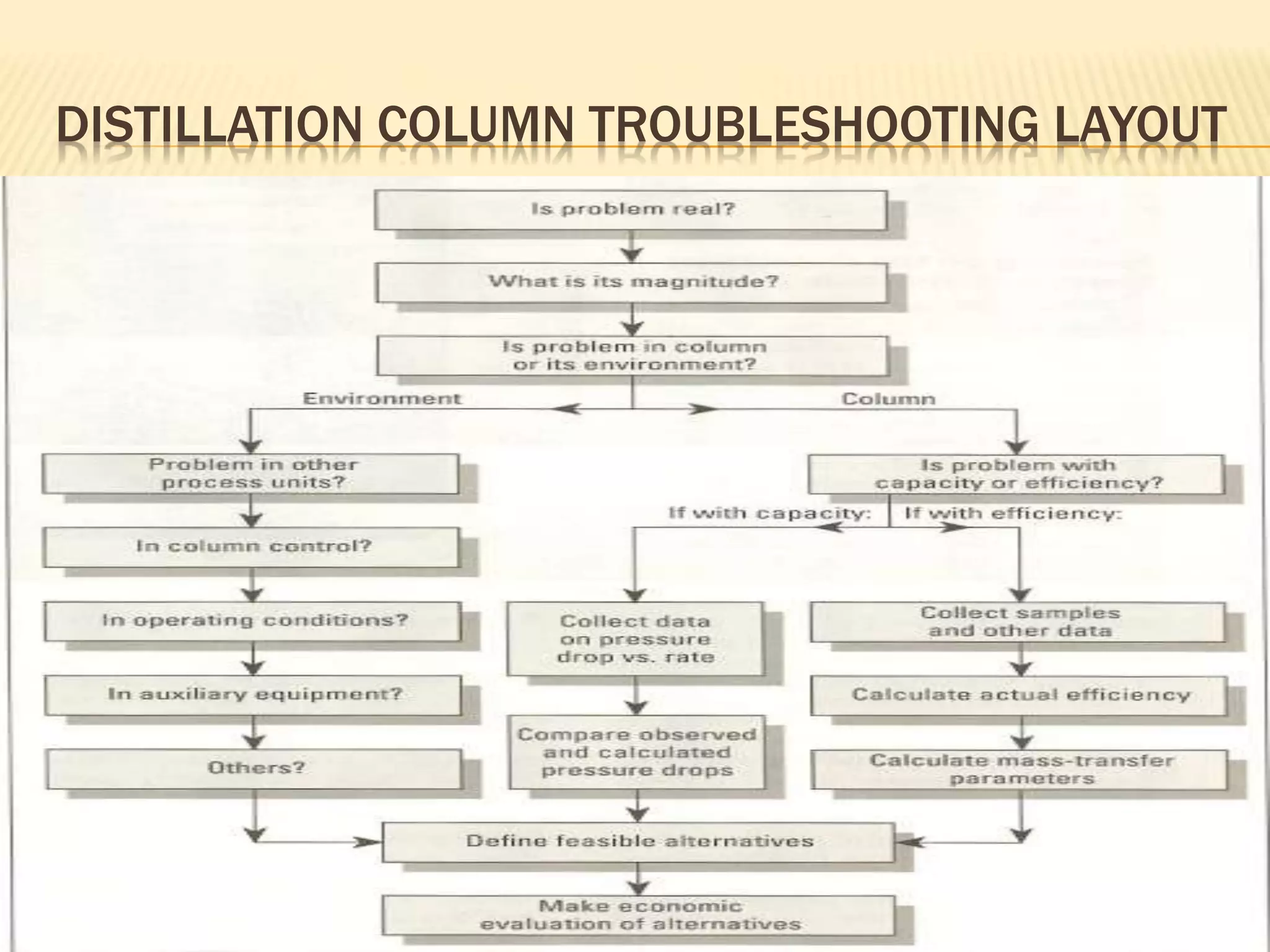

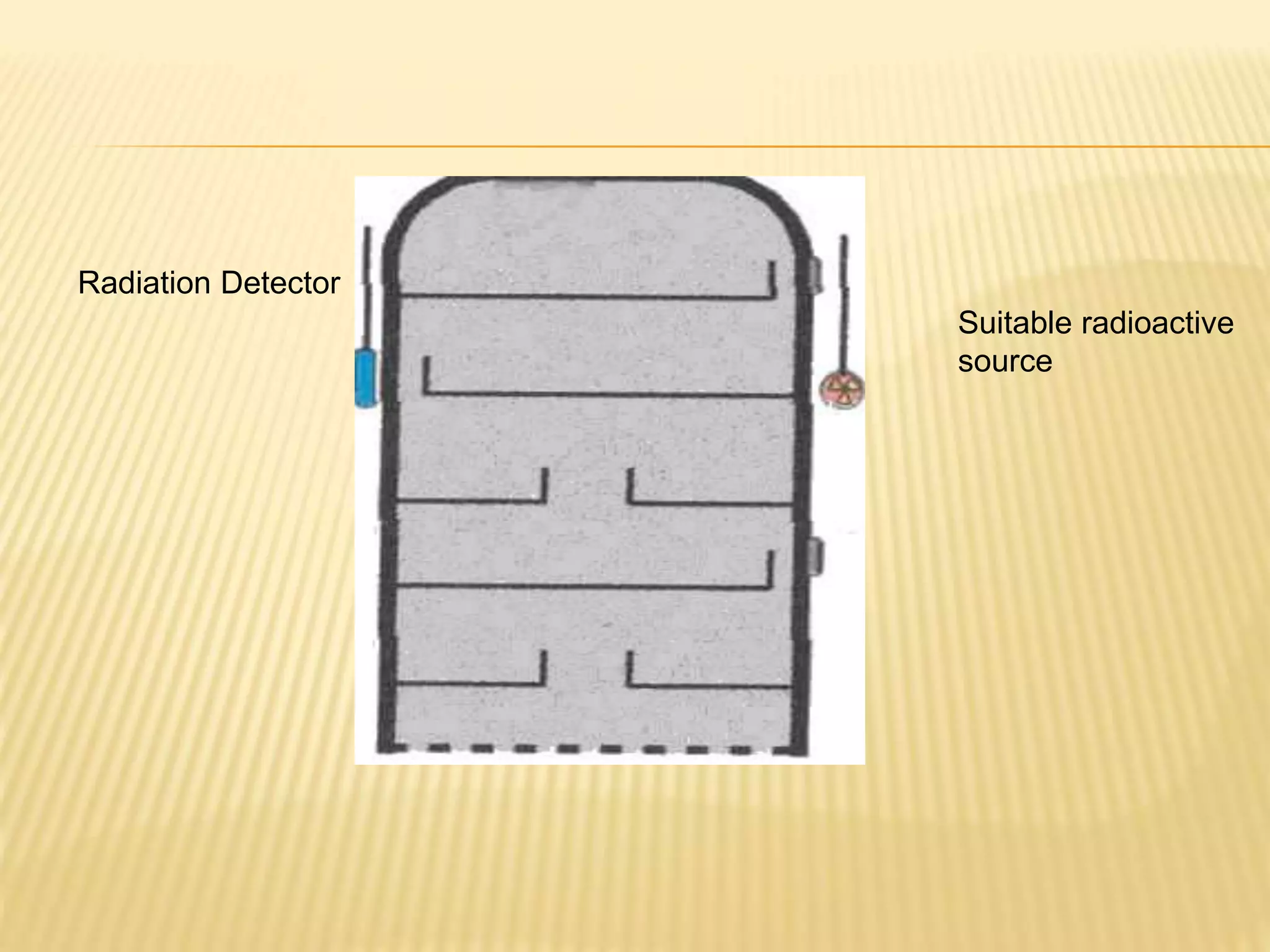

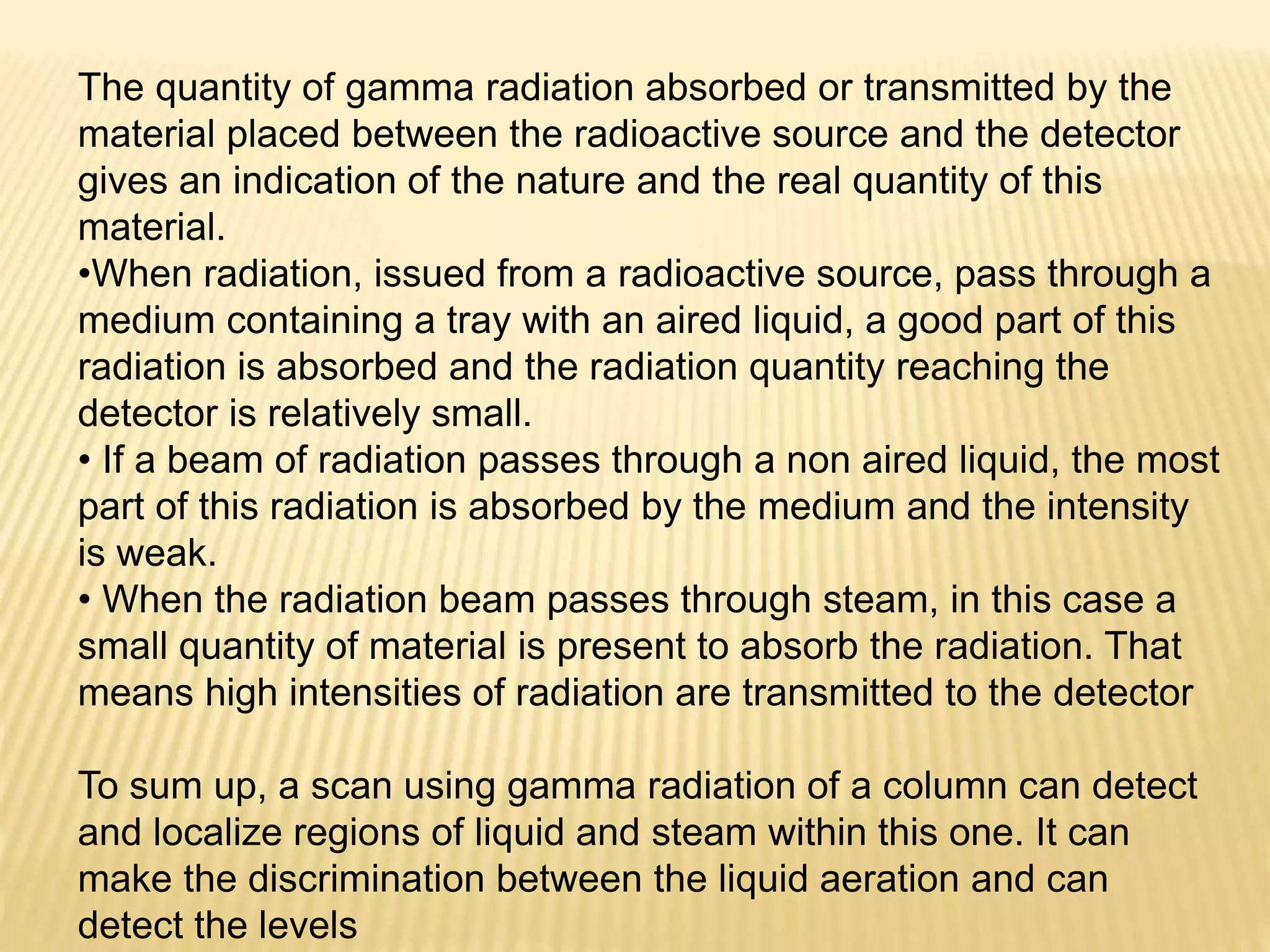

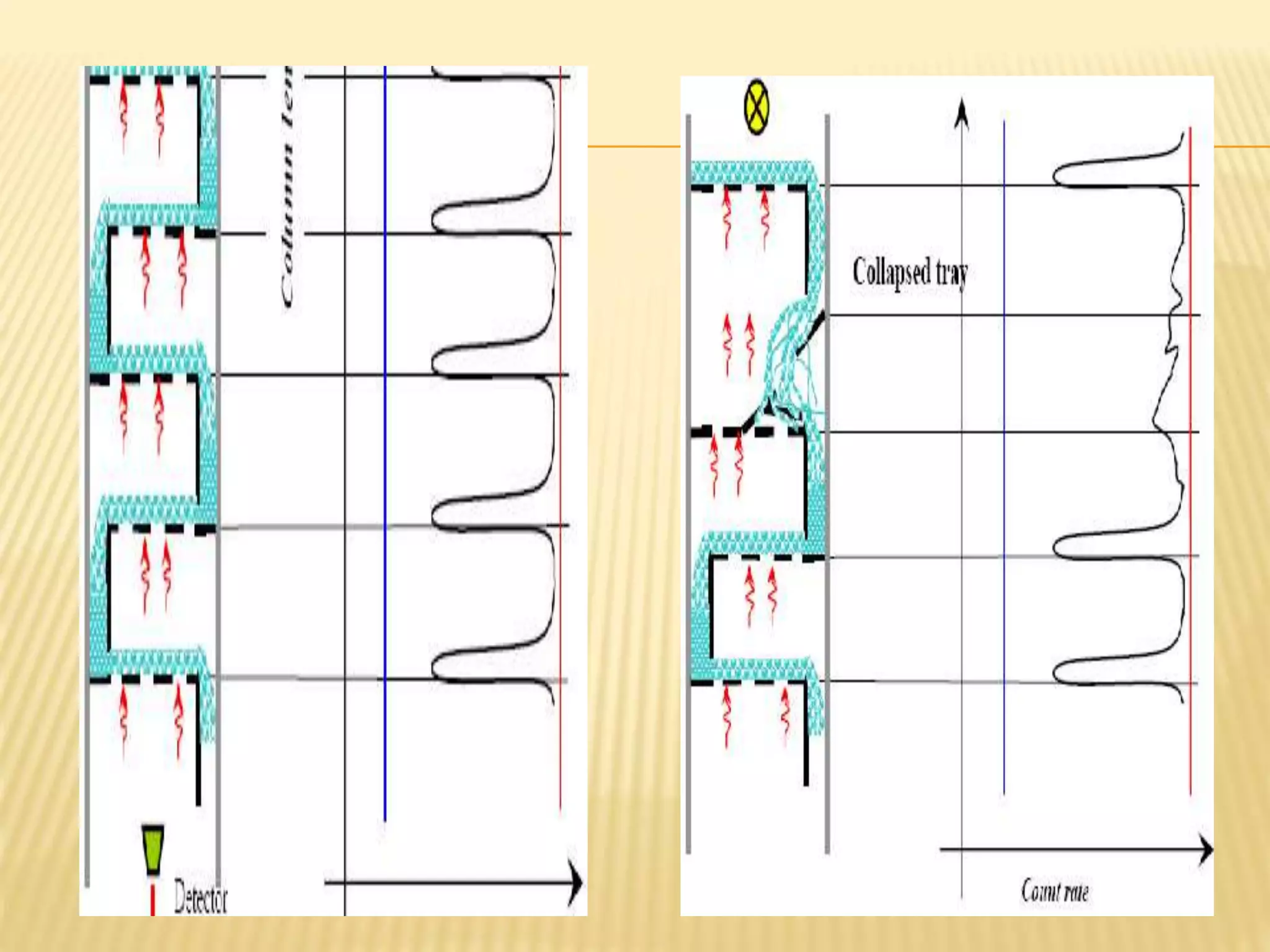

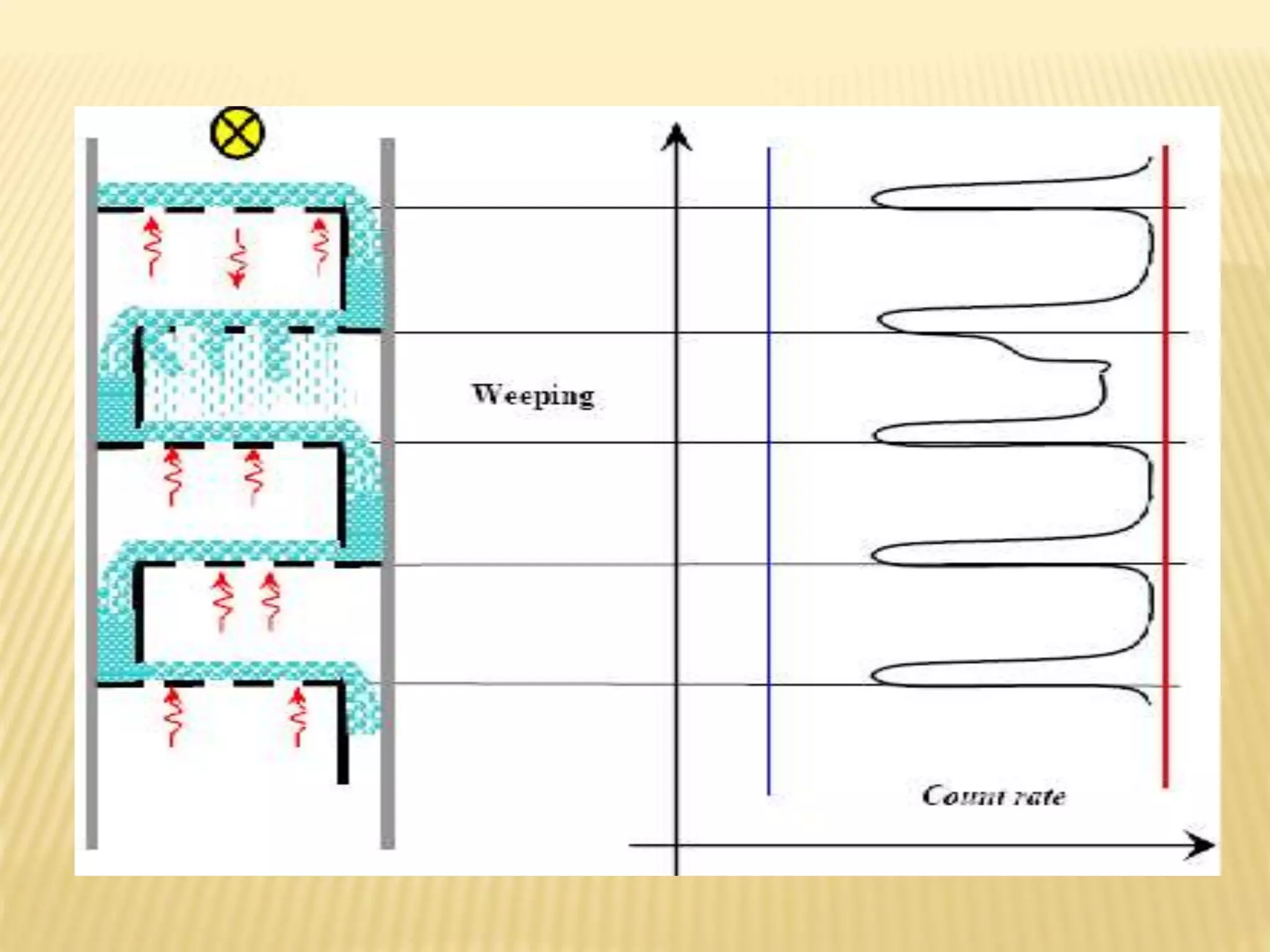

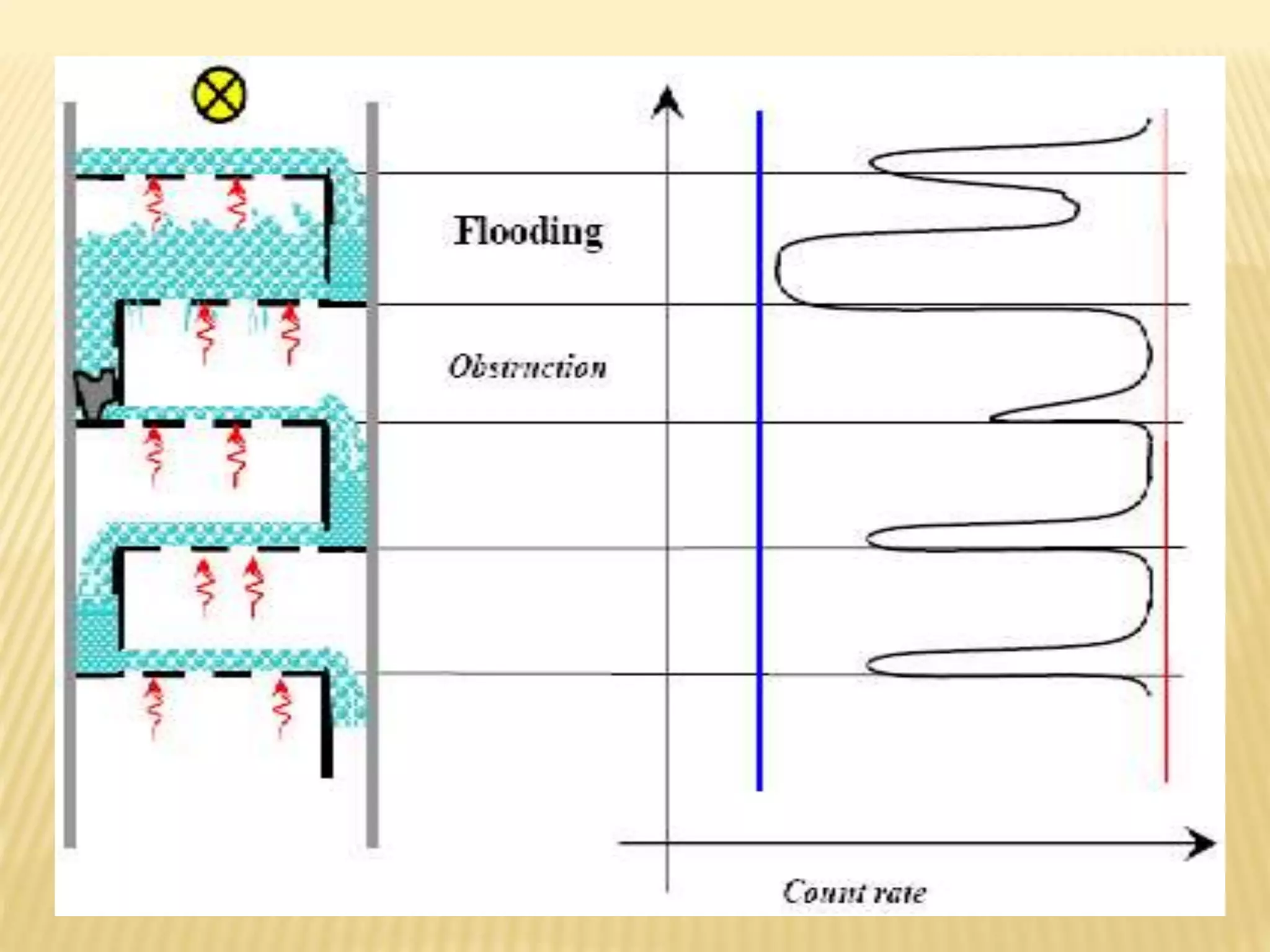

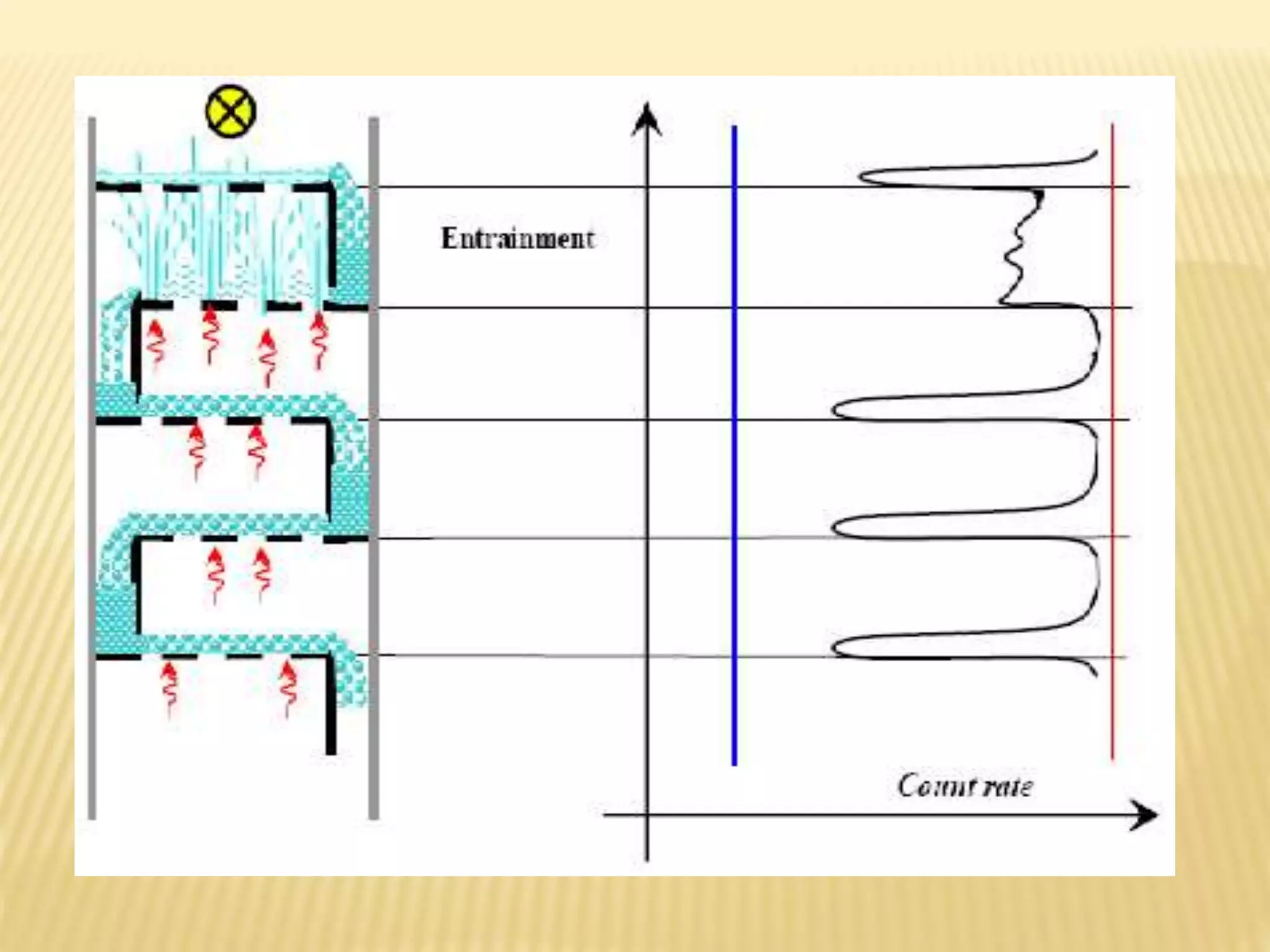

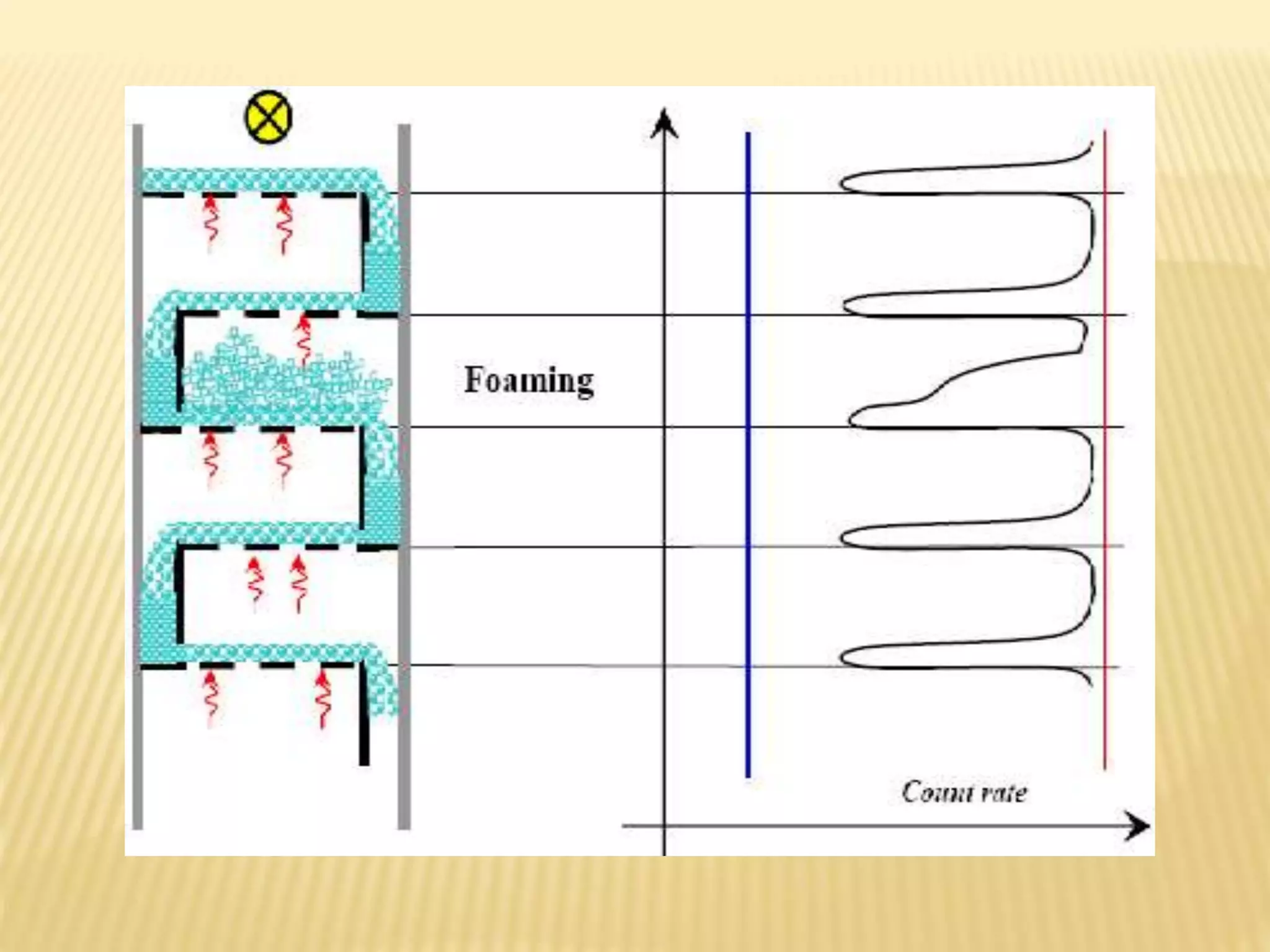

The document discusses the maintenance and troubleshooting of distillation columns in refineries, highlighting the critical nature of these components for plant performance. It identifies main problems like liquid entrainment and flooding, along with associated failure modes such as corrosion and human error. Recommendations for problem identification and prevention techniques are provided, emphasizing the need for advanced methods to resolve issues efficiently and safely.