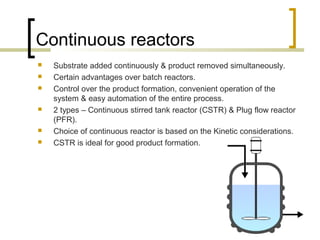

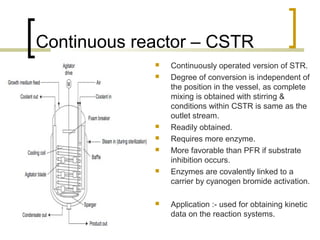

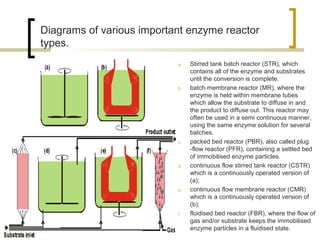

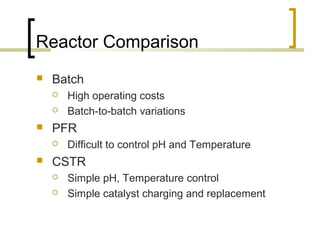

The document discusses immobilized enzyme reactors, categorizing them into batch and continuous types, highlighting their construction, advantages, disadvantages, and applications. It details different types of reactors, such as stirred tank batch reactors and fluidized bed reactors, along with operational considerations for effective enzyme action. Additionally, specific examples of enzyme applications in industries such as food and pharmaceuticals are provided, emphasizing the importance of reactor selection based on characteristics like reactant viscosity and conversion efficiency.

![Batch reactor – Stirred tank [STR]

Simplest form..

Good mixing, ease of temperature & pH

control.

Loss of some enzyme activity may occur.

Modified form – Basket Reactor.

Basket reactor – enzymes are retained

over the impeller blades or baffles of the

tank reactor.

Both have a well mixed flow pattern.

High shear forces may damage cells.

Requires high energy input.

Application :- free & immobilized enzyme

reactions..

Recovery of products produced by

enzymes like lipase, glucose isomerase &

B-galactosidase.](https://image.slidesharecdn.com/enzymereactor-161107064832/85/immobilized-Enzyme-reactors-batch-and-continuous-types-7-320.jpg)

![Batch reactor – Plug flow [PFR]

Alternative to flow pattern type of

reactors.

Flow rate controlled by a plug system.

Plug flow – Packed bed or Fluidized

bed

Used when inadequate product

formation in flow type reactors.

Advantage – external mass transfer

effects can be reduced by the

operational high fluid velocities.

Application :- used for obtaining

kinetic data on the reaction systems.](https://image.slidesharecdn.com/enzymereactor-161107064832/85/immobilized-Enzyme-reactors-batch-and-continuous-types-8-320.jpg)

![Batch reactor – Packed-bed [PBR]

Modified form, Widely used.

When equipped with external

heating & cooling coils is also

called as PFR

Substrate stream flows at same

velocity, parallel to reactor with

no back-mixing.

3 substrate flow possibilities –

downward flow method, upward,

& recycling method.

Packed-bed reactors are used

with immobilized or particulate

biocatalysts.

Medium can be fed either at the

top or bottom & forms a

continuous liquid phase.](https://image.slidesharecdn.com/enzymereactor-161107064832/85/immobilized-Enzyme-reactors-batch-and-continuous-types-9-320.jpg)

![Batch reactor – Fluidised-bed [FBR]

Intermediate between CSTRs & PBRs.

Consist of a bed of immobilized

enzymes which is fluidized by rapid

upwards flow of the substrate or in

combination with a gas or Secondary

liquid stream.

Fluidization requires large power input.

Heating & cooling coils are located

outwards.

Baffles are used to decrease stirring

efficiency.

Useful if the reaction involves the

utilization or release of gaseous

material.

Disadvantage – difficulty in scaling-up

these reactors.](https://image.slidesharecdn.com/enzymereactor-161107064832/85/immobilized-Enzyme-reactors-batch-and-continuous-types-10-320.jpg)