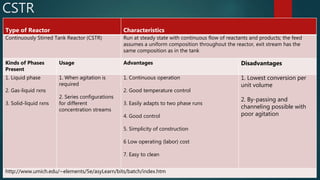

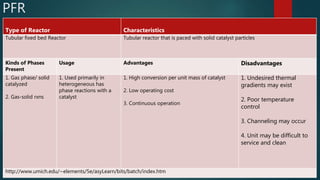

The document describes four types of chemical reactors: batch reactors, continuously stirred tank reactors (CSTR), plug flow reactors (PFR), and tubular fixed bed reactors.

Batch reactors operate by charging reactants, allowing the reaction to proceed without additional input or output until complete. CSTRs operate continuously with steady input and output of reactants and products to maintain a uniform composition. PFRs are arranged as one long reactor or many short reactors where concentration changes along the length. Tubular fixed bed reactors are tubular with a packed solid catalyst.