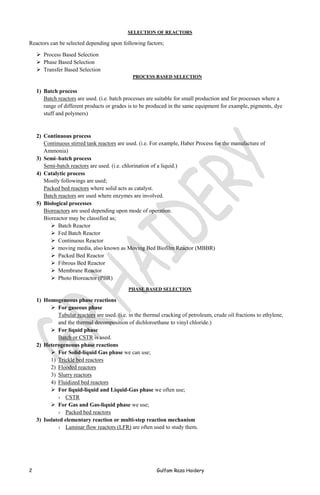

This document discusses the classification and selection of chemical reactors. It outlines the basic types of reactors including batch, continuous stirred-tank (CSTR), and plug flow reactors (PFR). Selection of reactors depends on factors such as the process type (batch, continuous, catalytic), phase (gas, liquid, solid), and required mass and heat transfer rates. For example, batch reactors are used for small batch production while CSTRs are common for liquid reactions requiring mixing. PFRs provide higher efficiency and are used when significant heat transfer is needed. Selection also considers whether the reaction involves single or multiple steps.