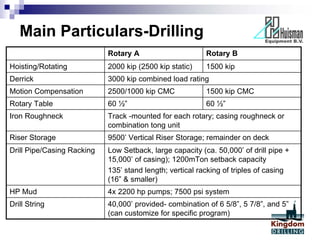

This document discusses opportunities to improve the efficiency and safety of deepwater drilling rigs and operations. It describes the key activities that rigs should be capable of, such as exploratory drilling, well testing, and subsea completions. Areas for improvement include reducing tubular handling times, improving tripping efficiency, and advancing well control systems. The document also discusses reducing failures through standardization, training, and system audits. Concurrent operations and reducing well times can lower costs. Storage capacities, logistics management, and power systems are also addressed.