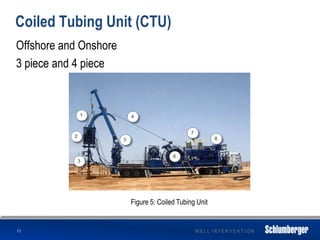

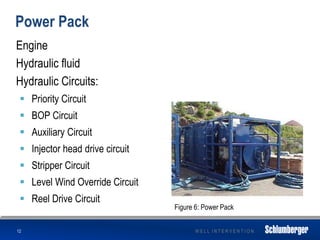

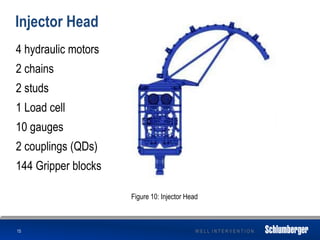

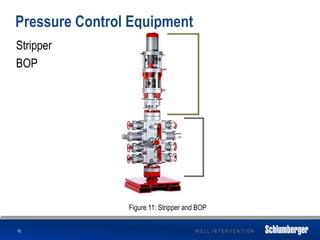

This presentation summarizes Schlumberger's well intervention process using coiled tubing units. It discusses Schlumberger's safety plan and techniques for injury prevention. It then provides an overview of the coiled tubing unit components including the power pack, control cabin, coiled tubing reel, injector head, and pressure control equipment. It also briefly discusses fluid and tool conveyance applications of coiled tubing as well as other learnings around pumping systems and inventory management. The presentation aims to provide a high-level overview of Schlumberger's well intervention process with coiled tubing.