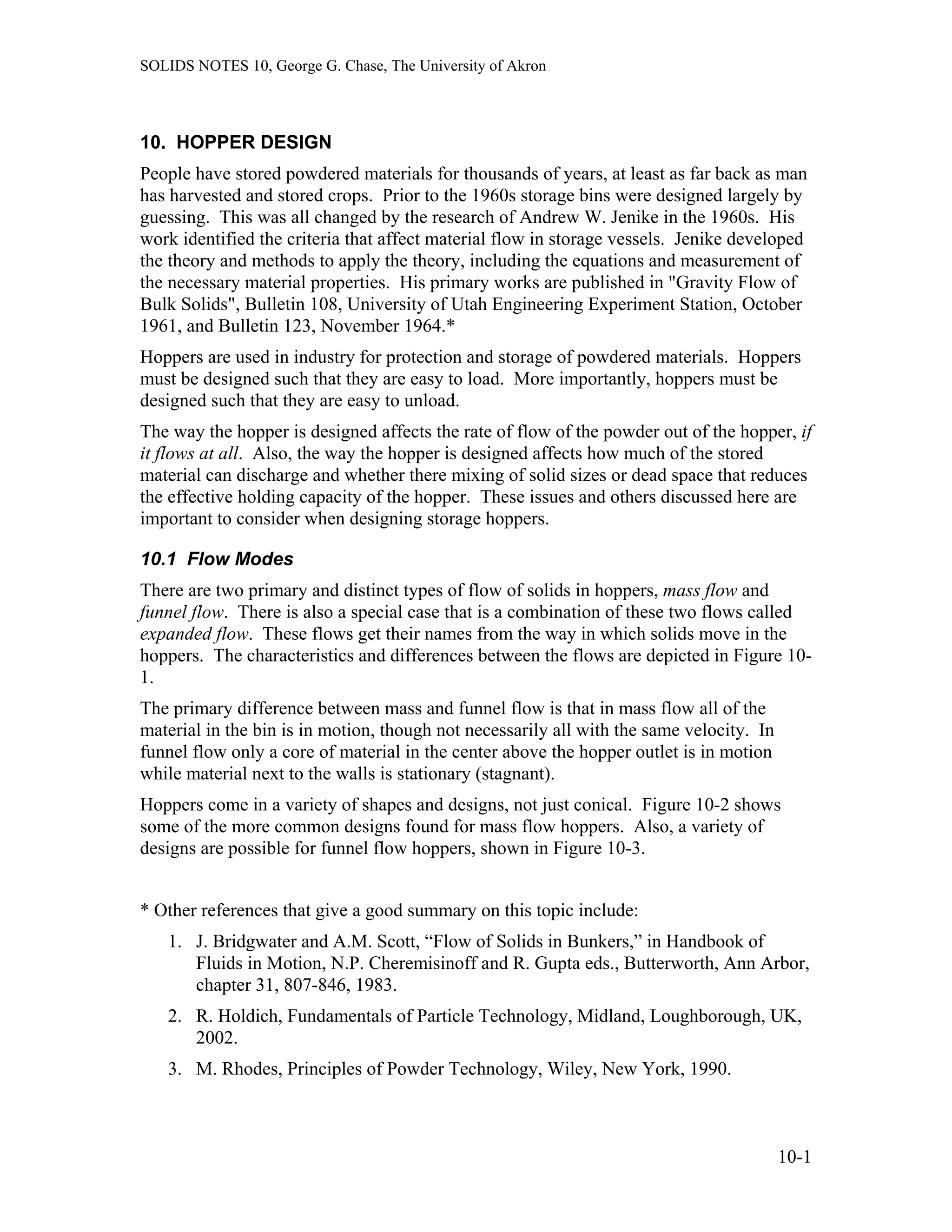

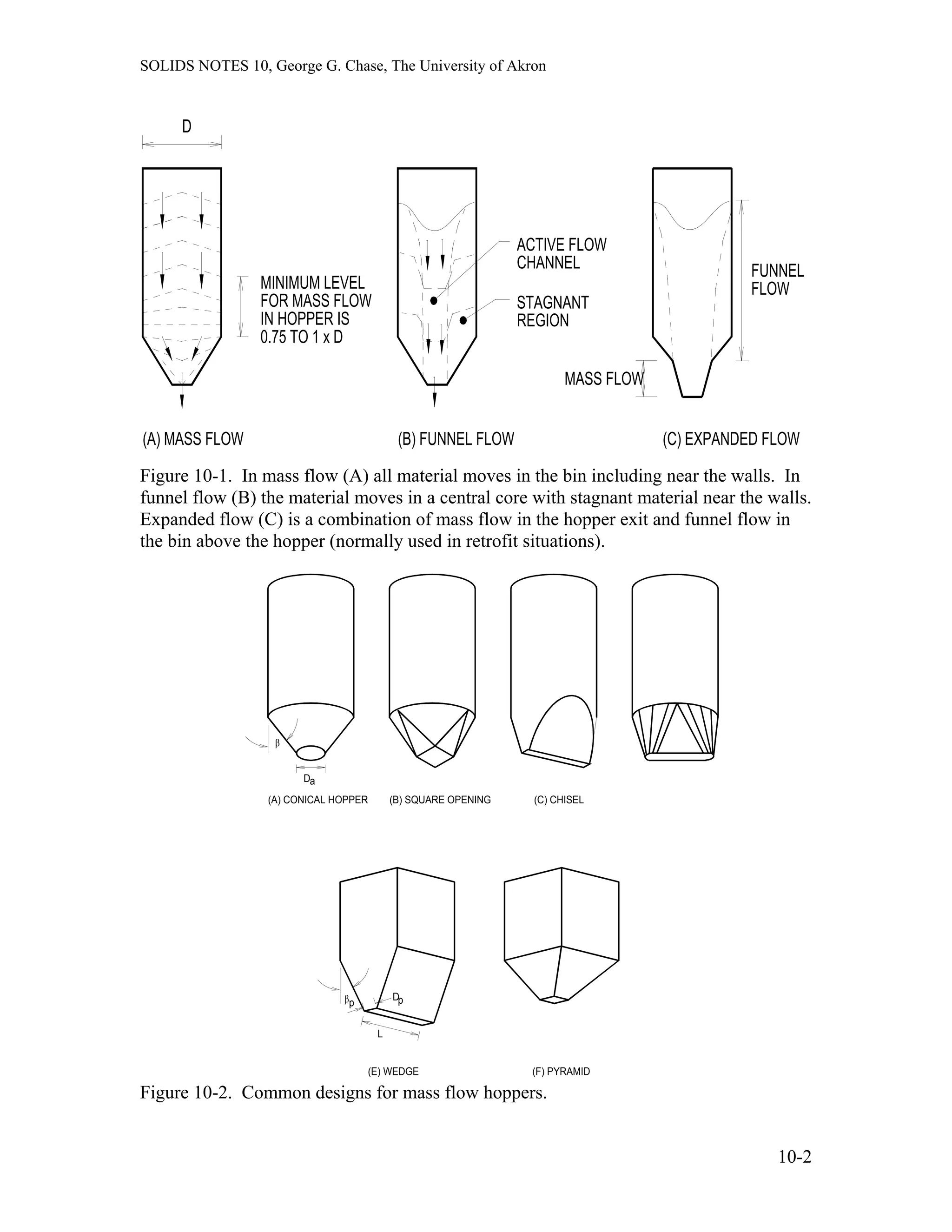

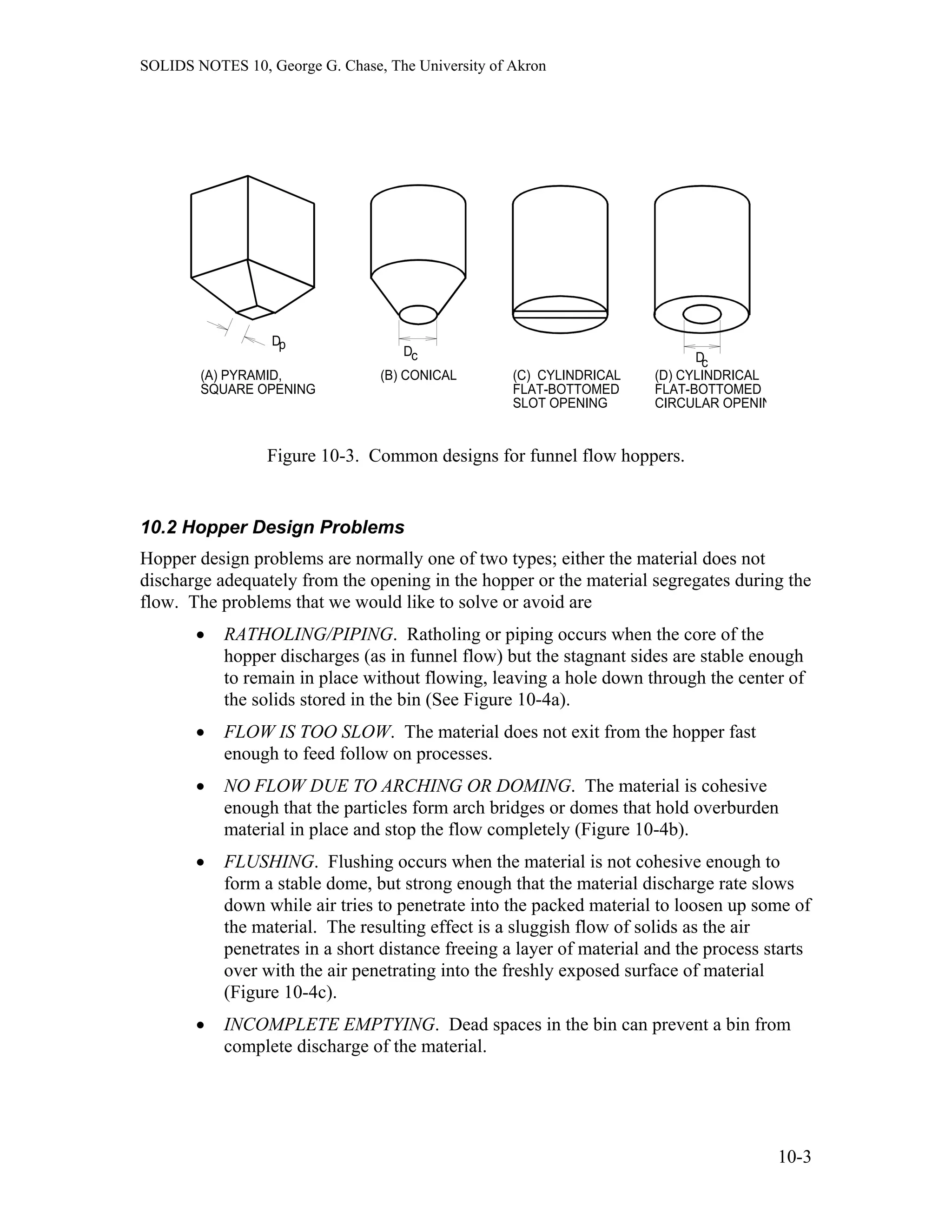

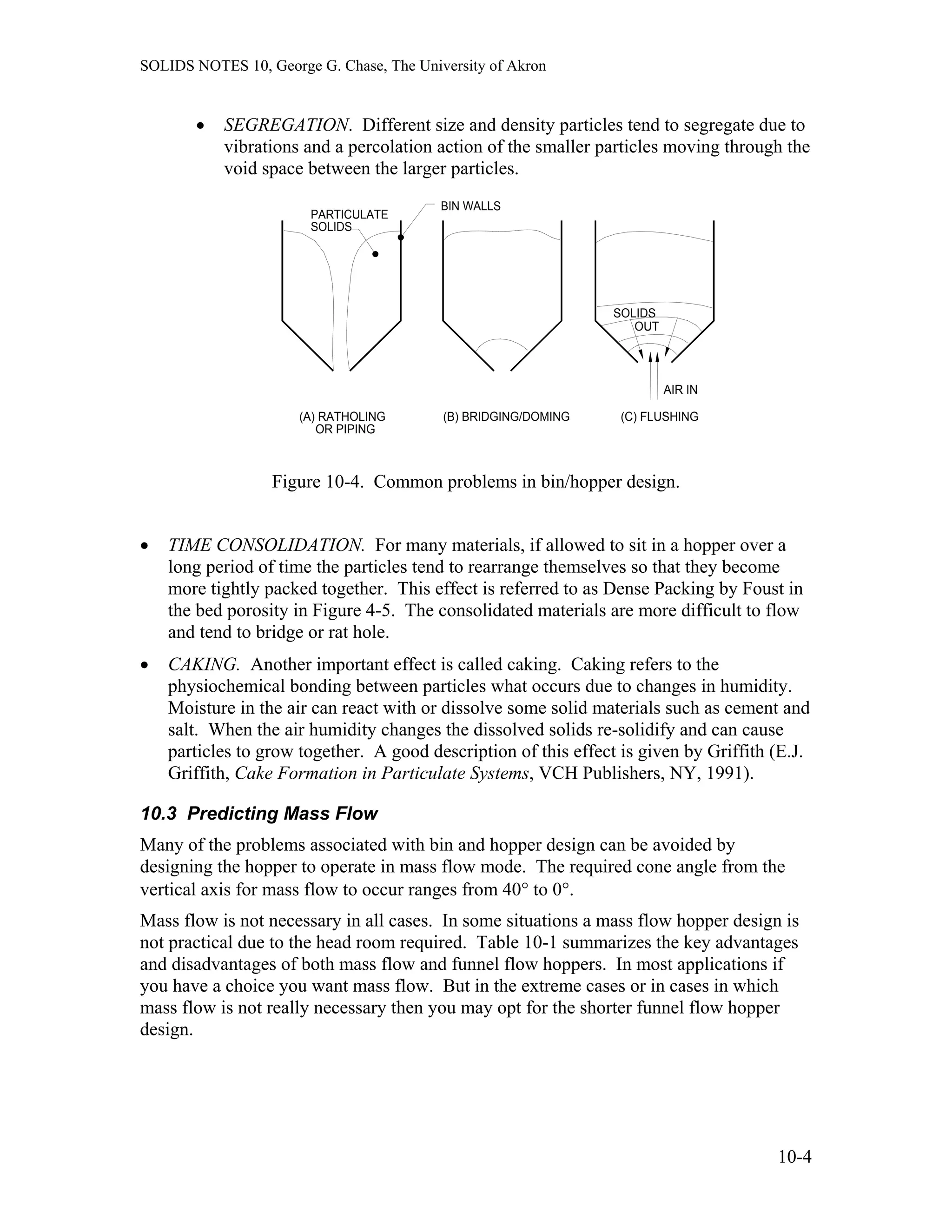

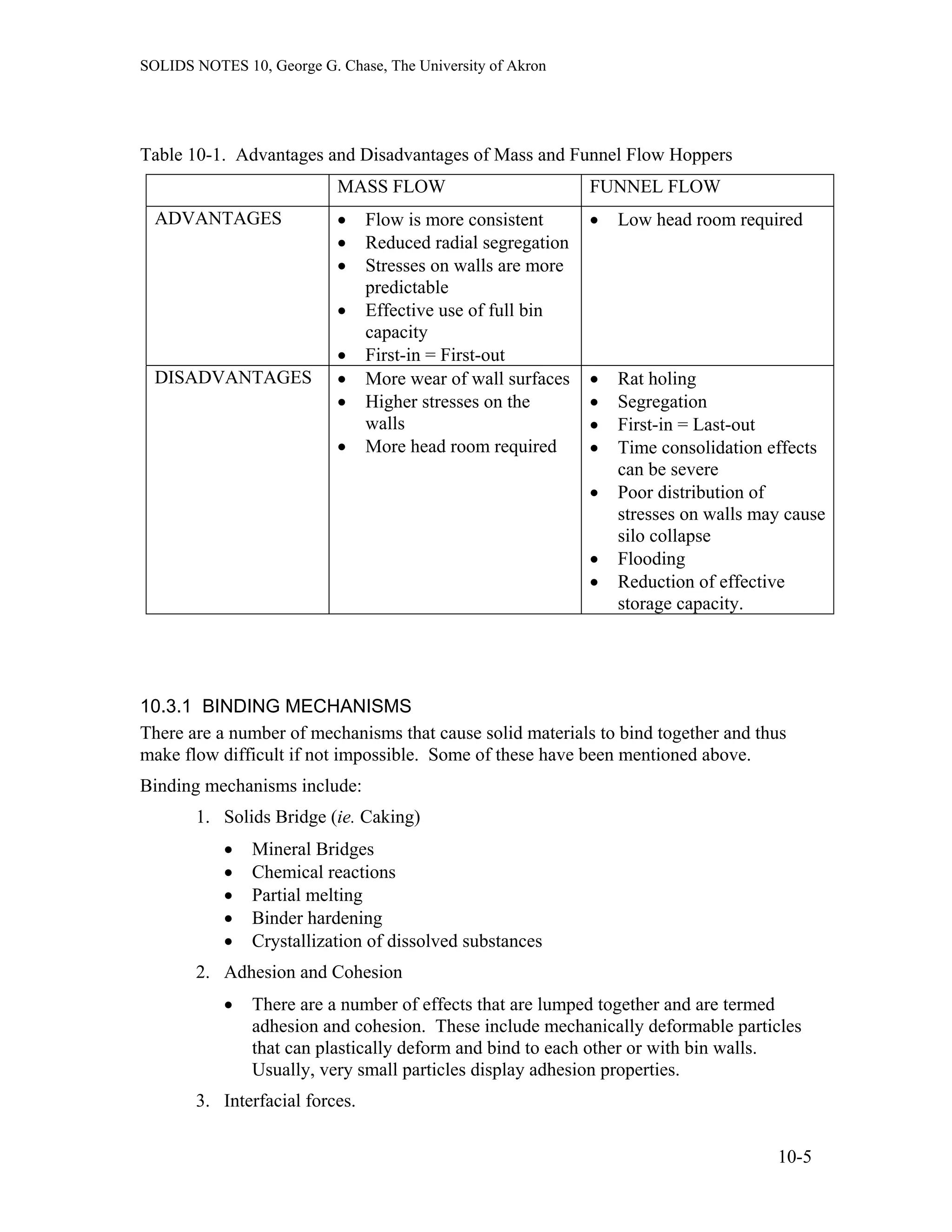

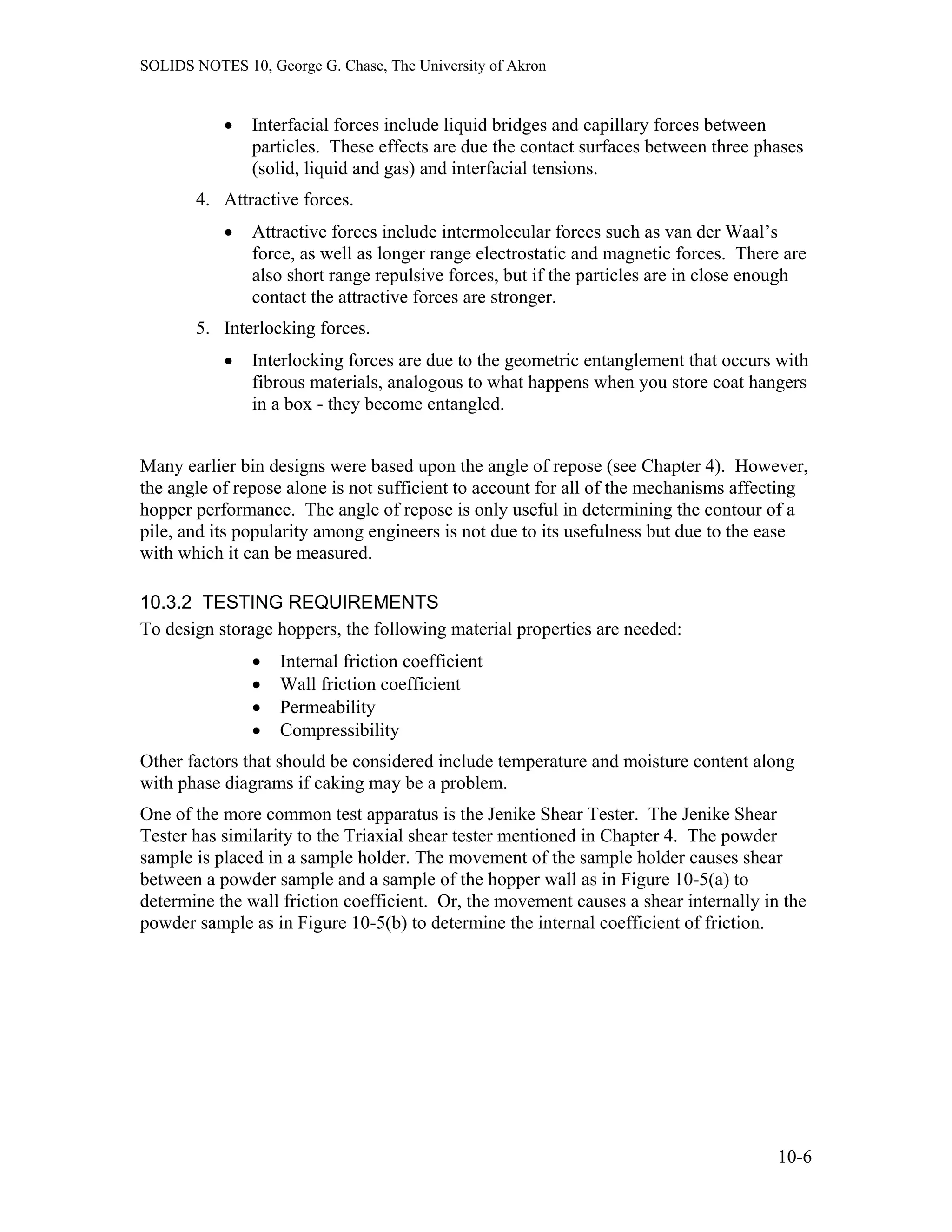

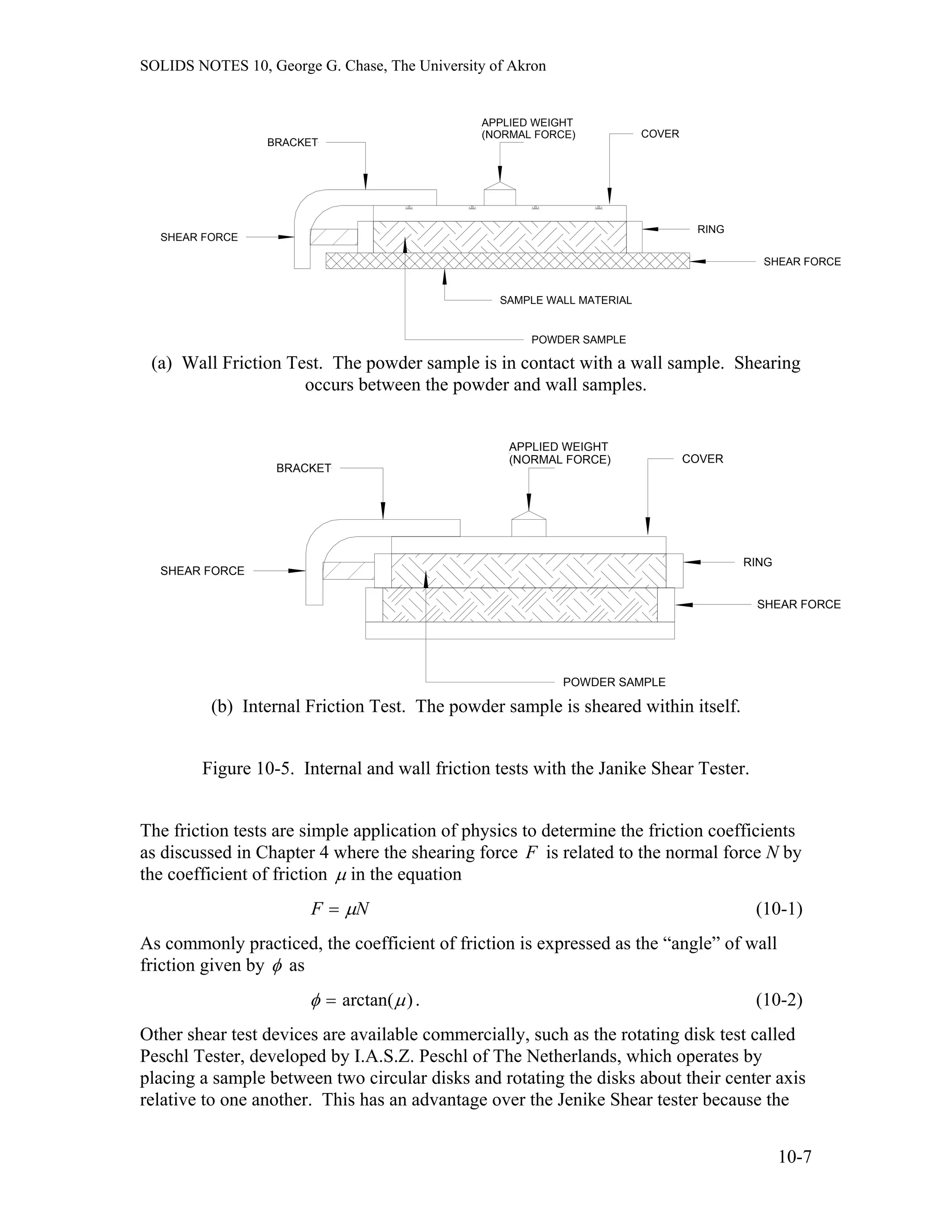

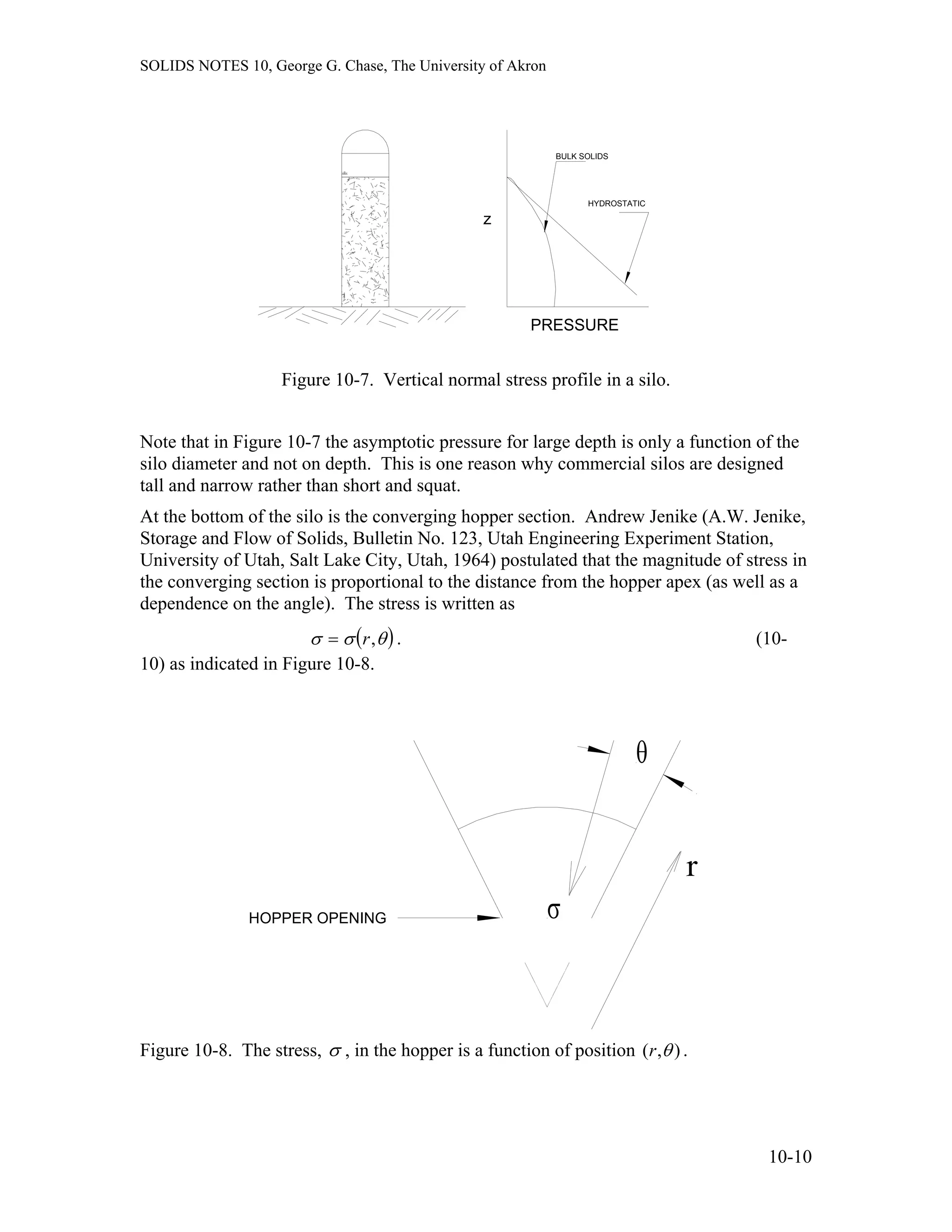

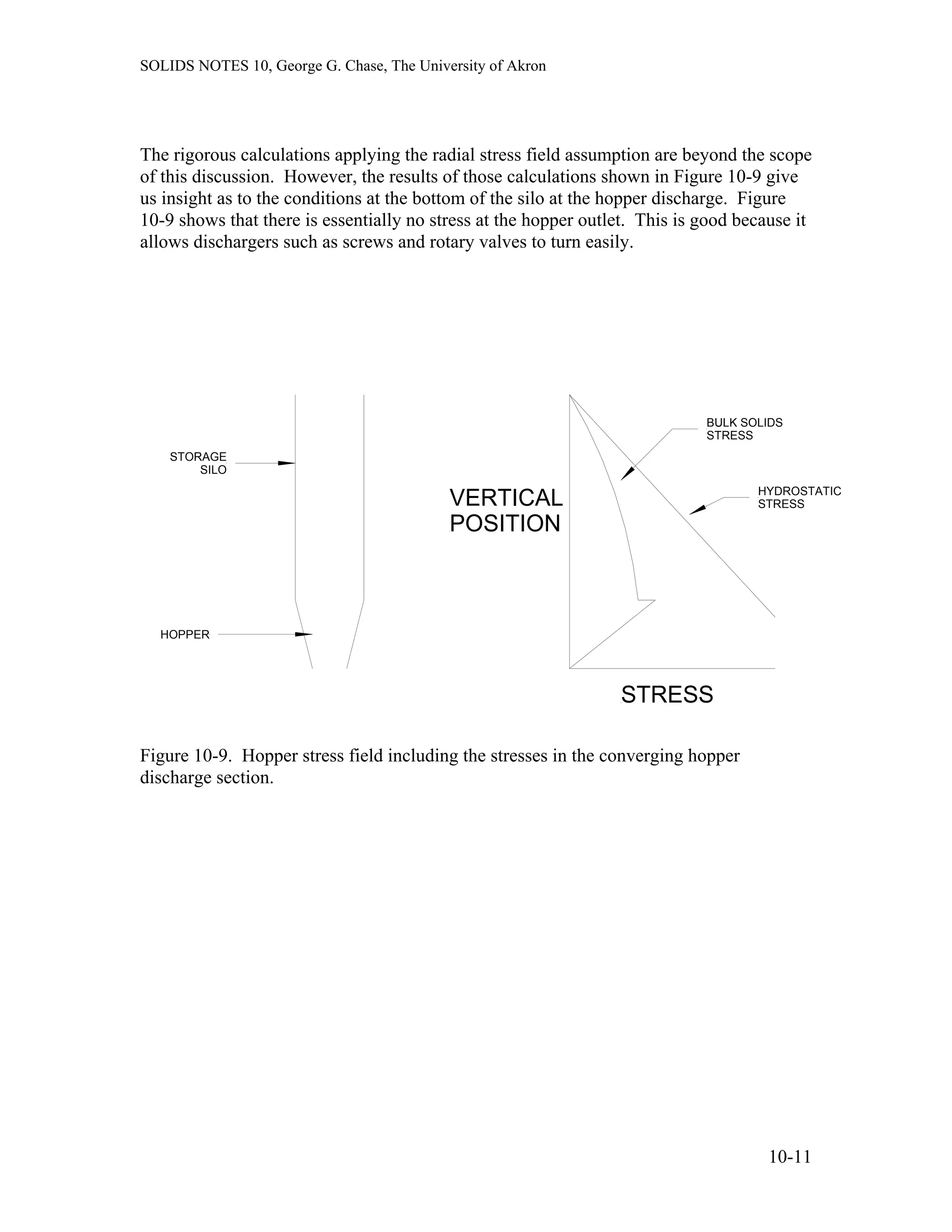

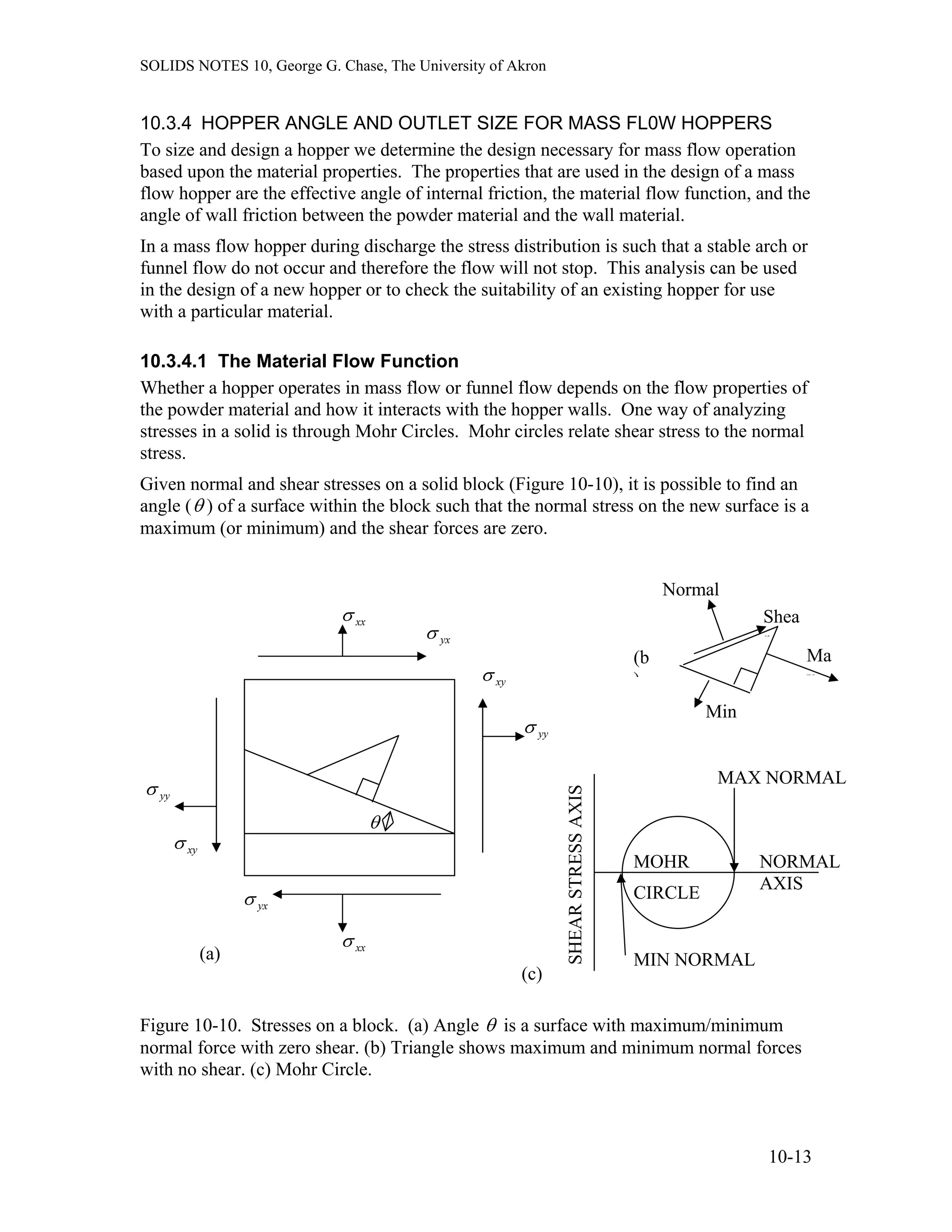

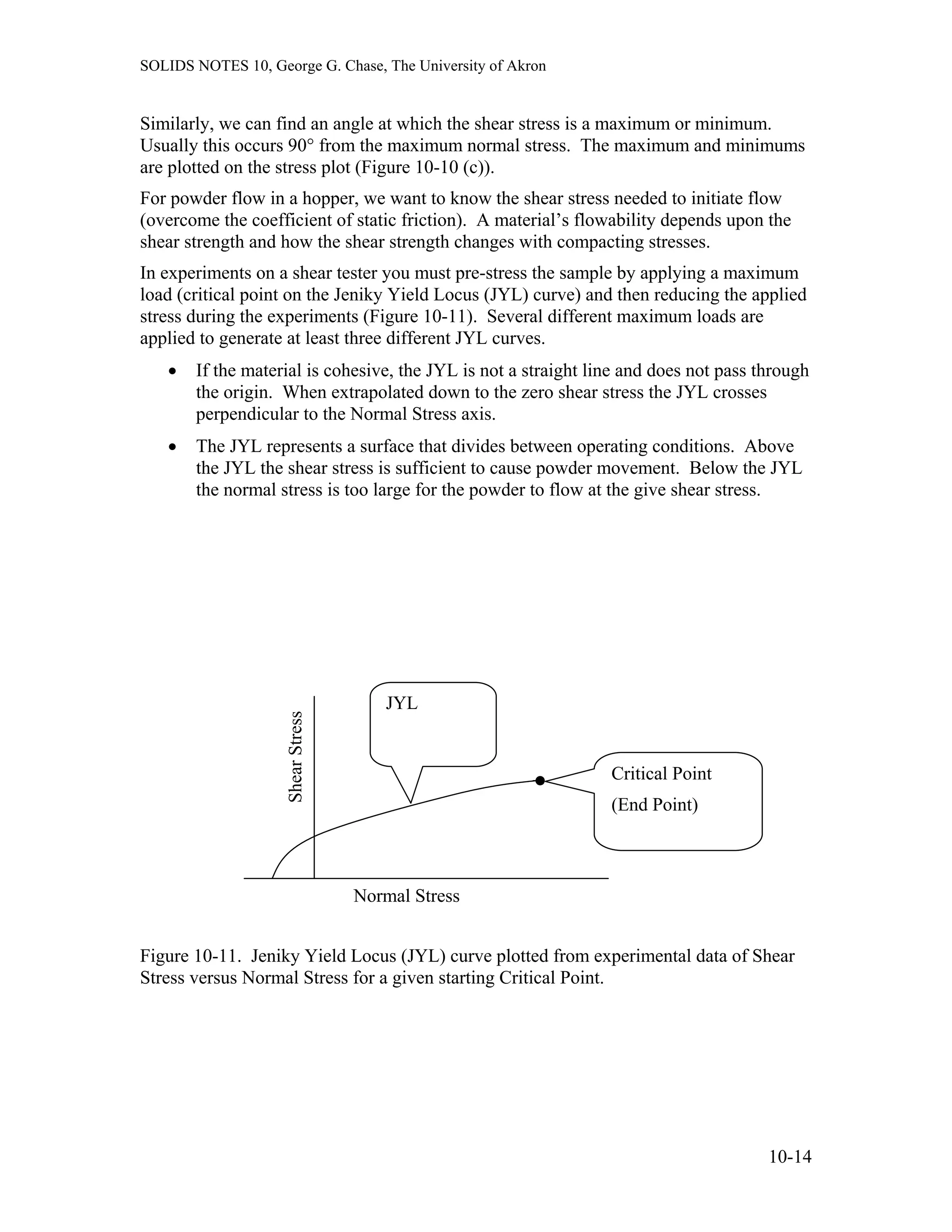

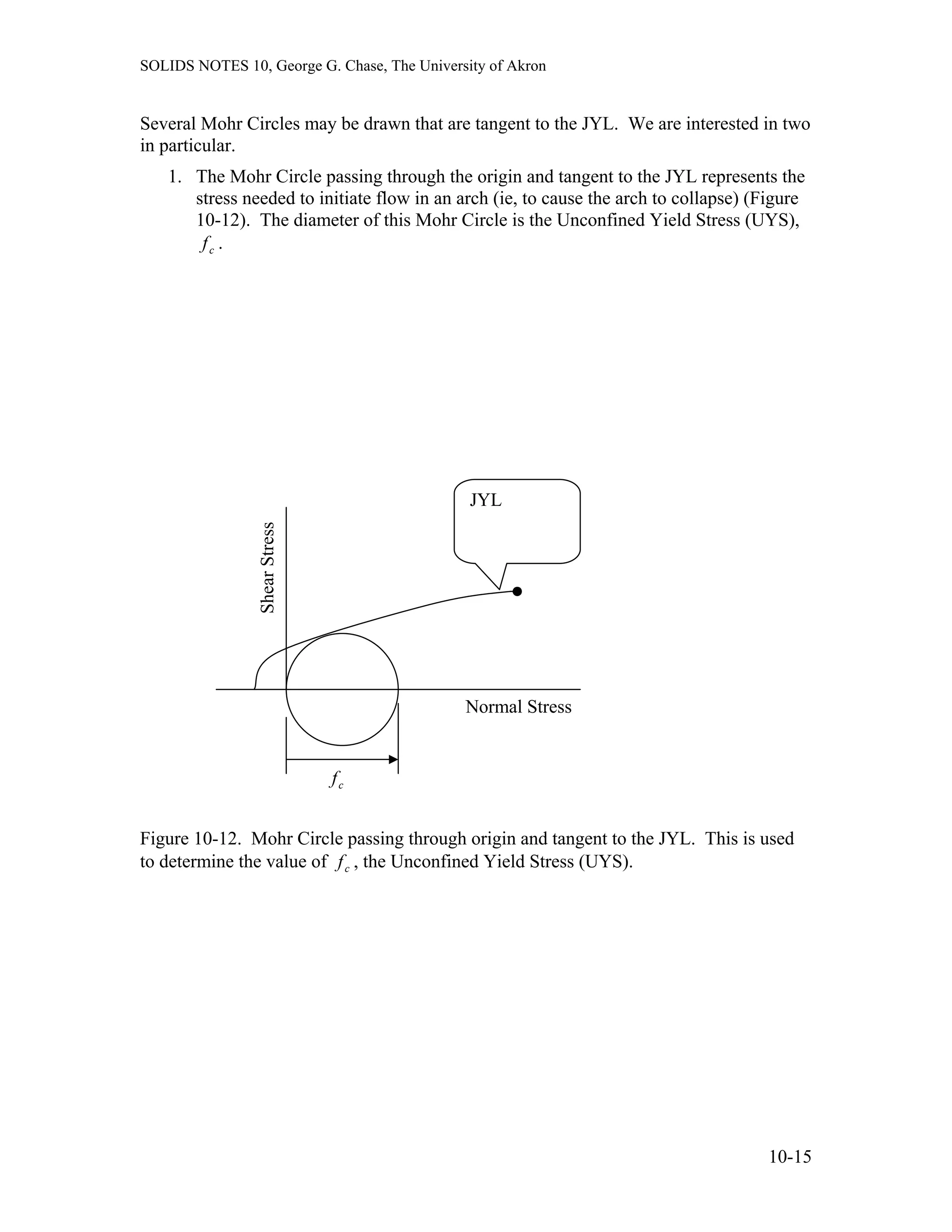

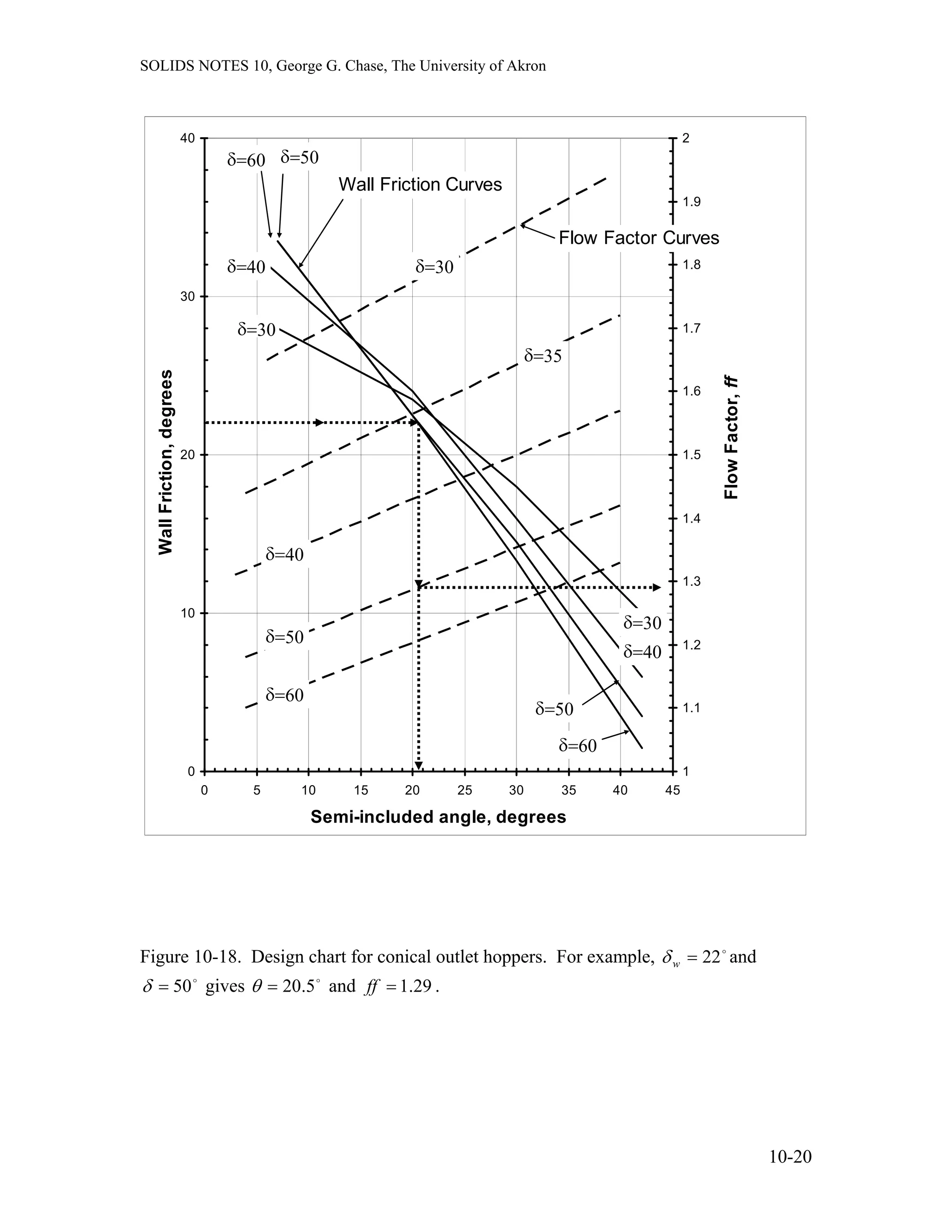

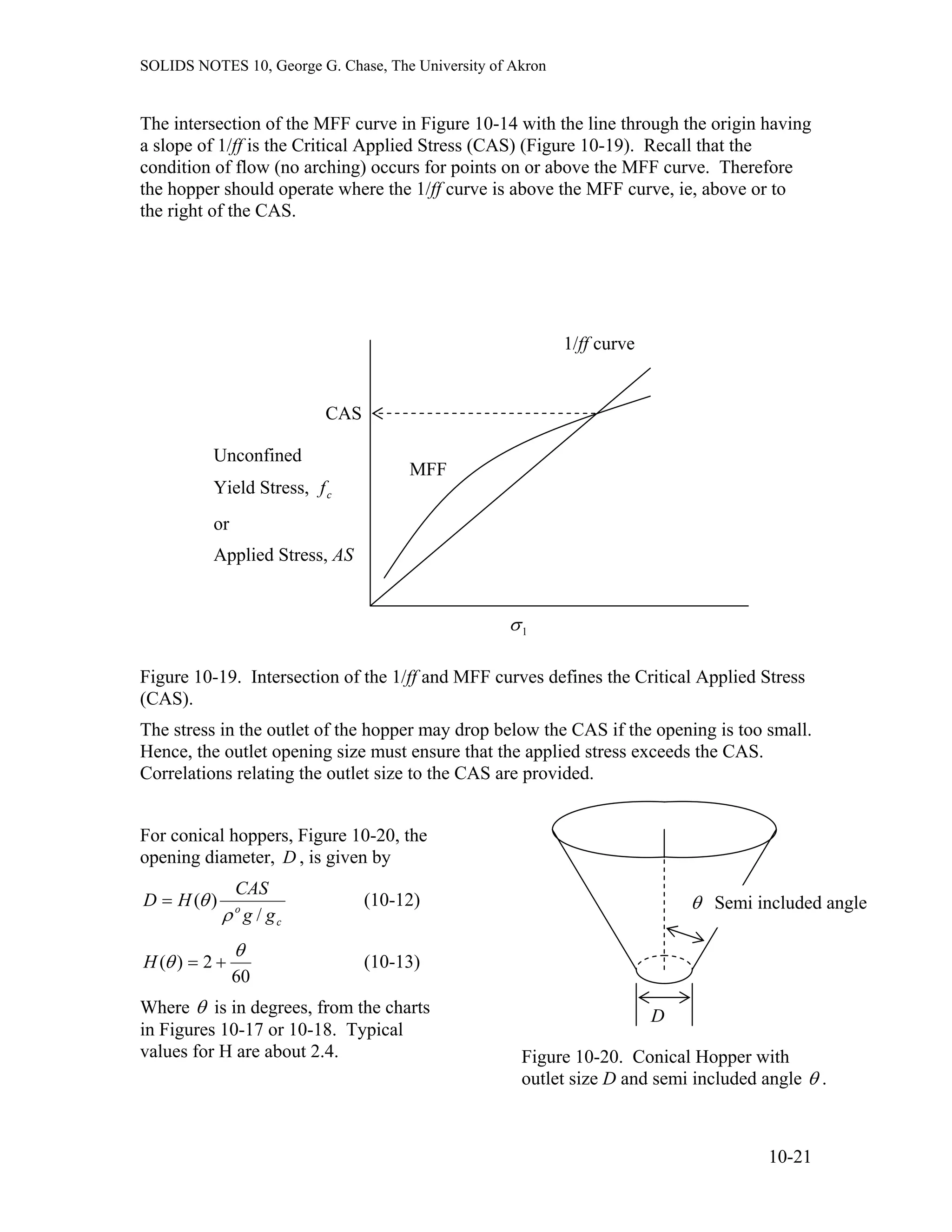

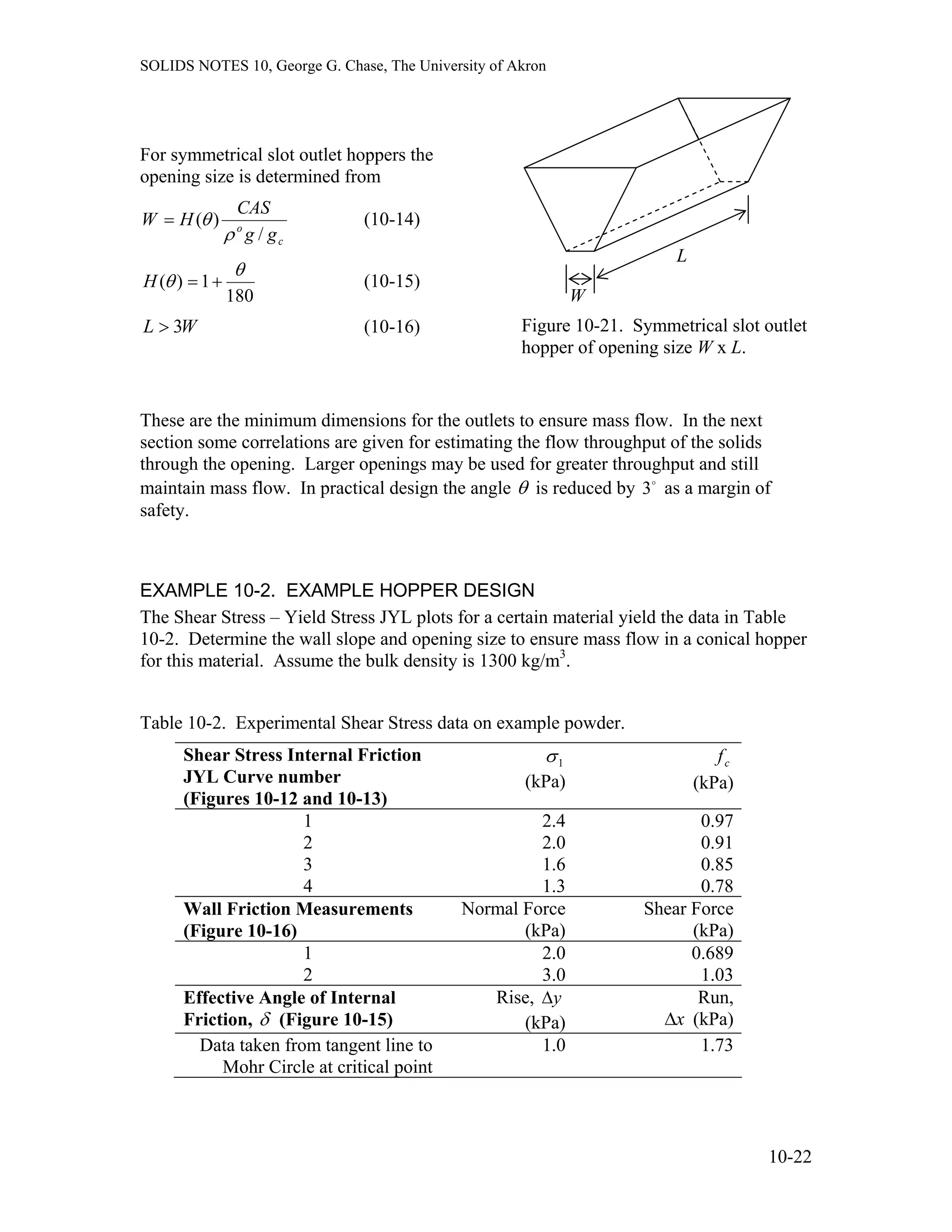

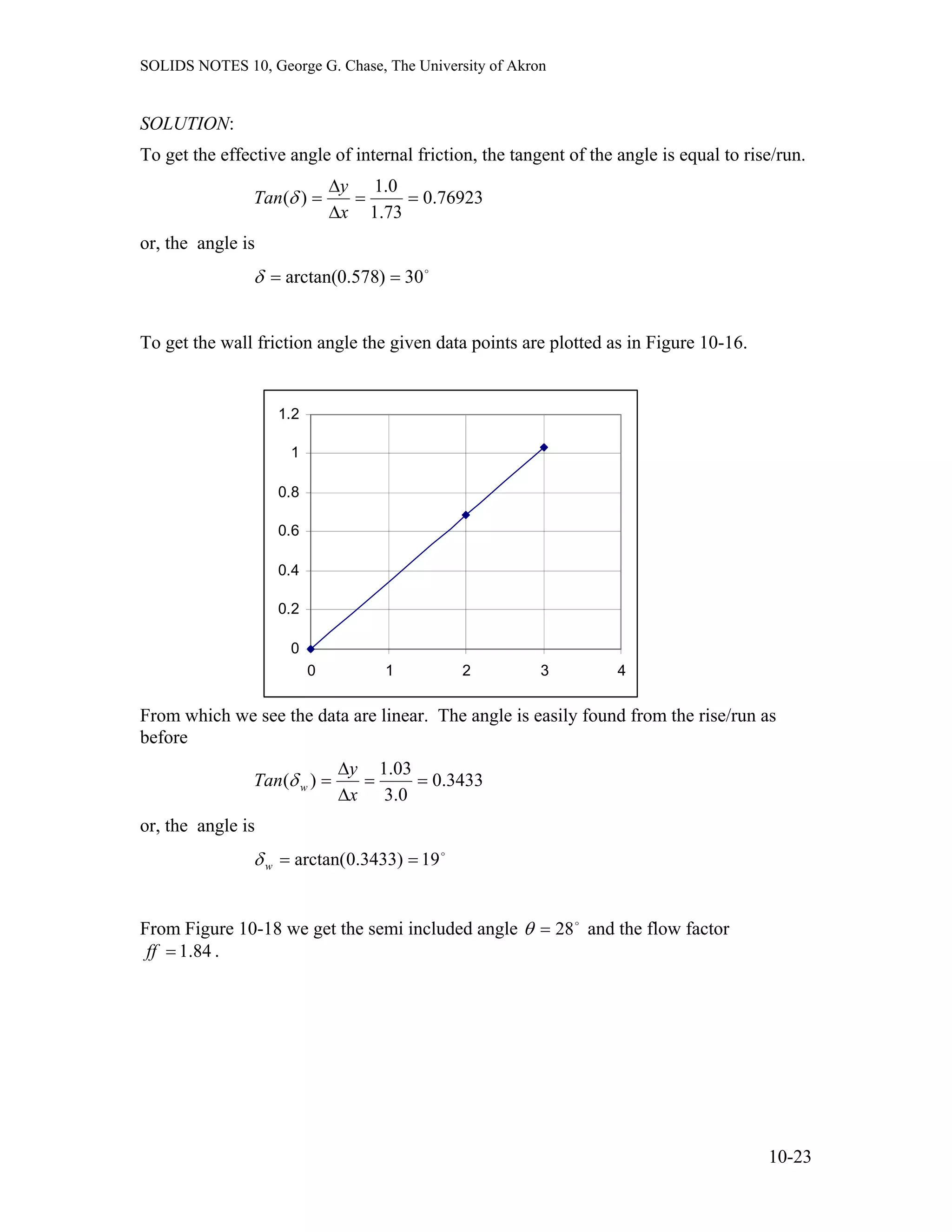

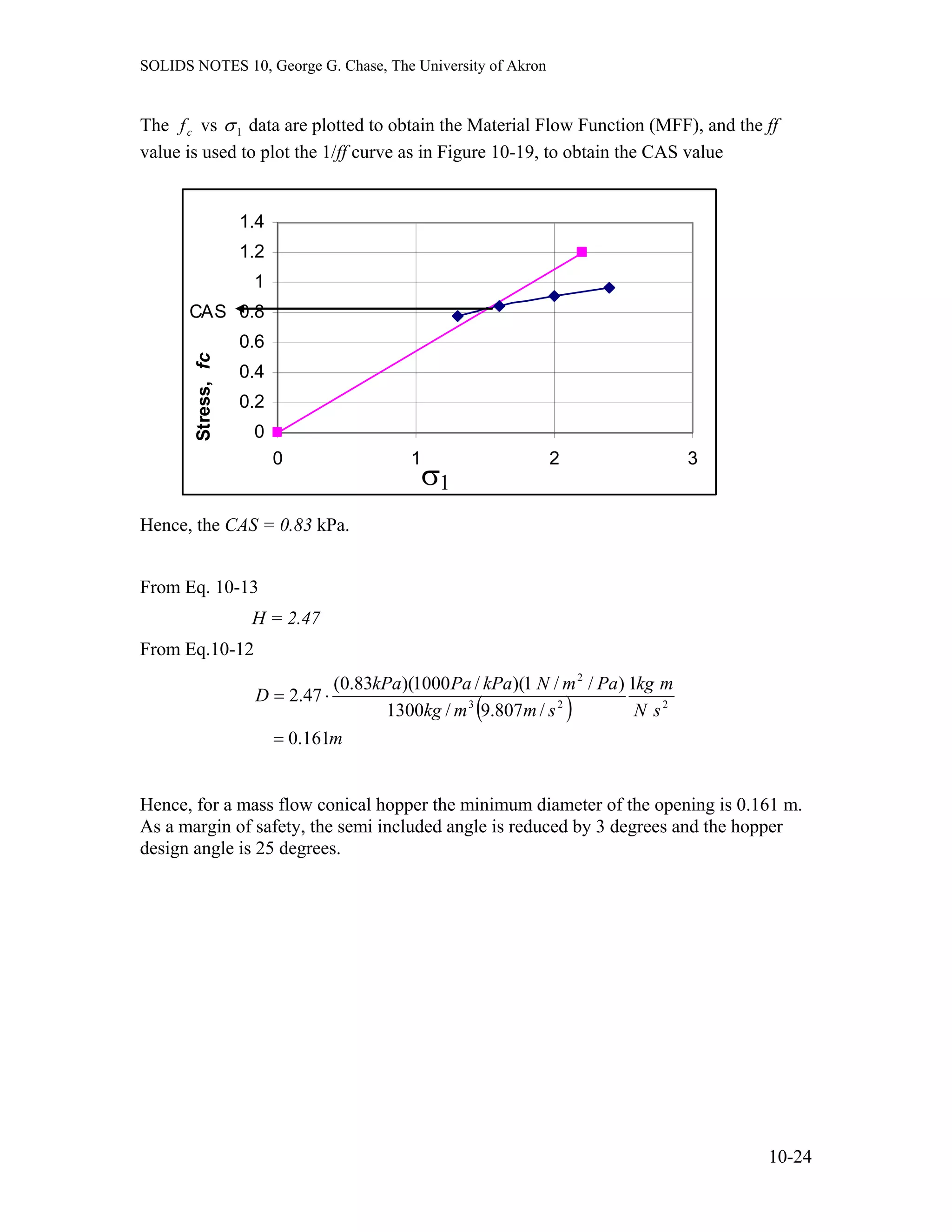

This document discusses hopper design for storing powdered materials. It begins by explaining the historical development of hopper design, noting that Andrew Jenike's work in the 1960s established the theory and methods for properly designing hoppers based on material flow properties. The document then discusses the different modes of material flow in hoppers - mass flow, funnel flow, and expanded flow. It identifies problems that can occur in hopper design like ratholing, arching, or segregation. The key to proper design is predicting mass flow, which depends on material properties like internal friction that must be tested for using equipment like the Jenike Shear Tester. Mass flow hoppers have advantages over funnel flow but require more headroom.