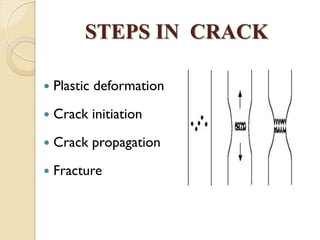

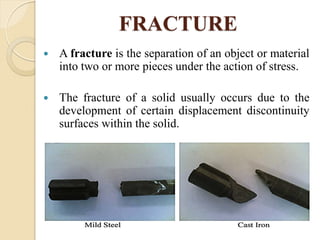

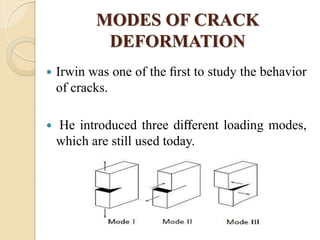

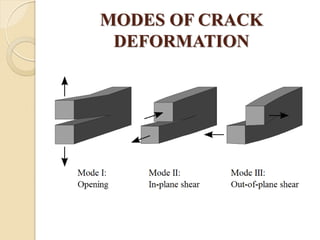

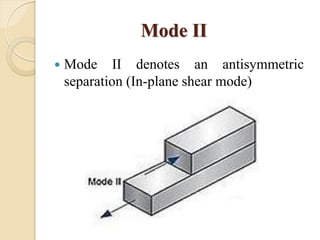

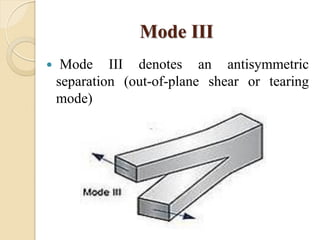

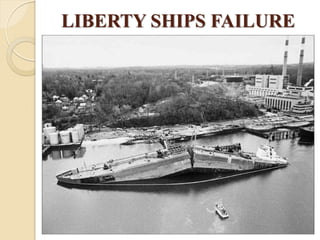

The document discusses crack deformation modes and failure in materials, emphasizing various forms of cracks such as fatigue, creep, and corrosion. It explores the stages of crack initiation and propagation, along with classifications of fractures, notably ductile and brittle fractures. Additionally, it outlines three loading modes of crack deformation as introduced by Irwin: opening mode, in-plane shear, and out-of-plane shear.