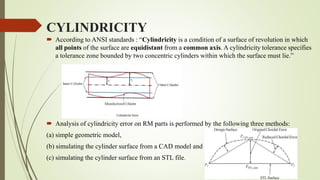

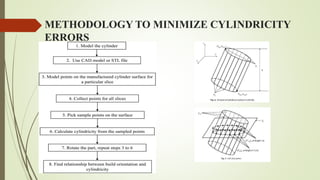

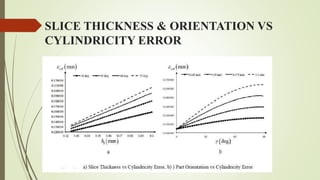

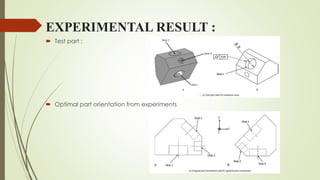

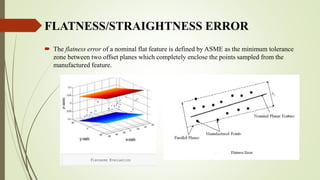

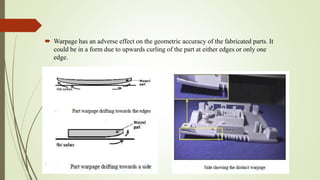

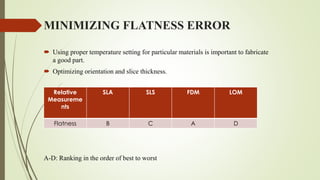

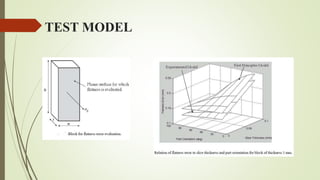

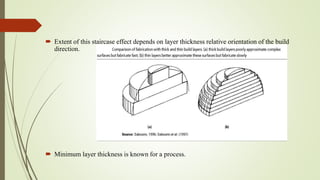

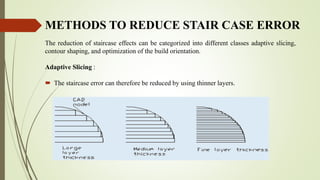

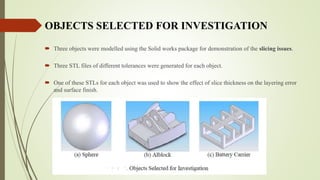

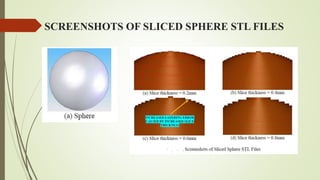

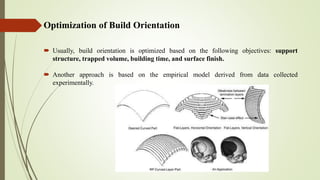

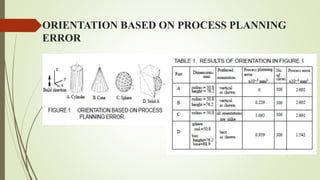

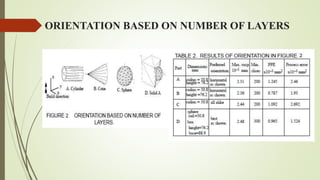

This document summarizes research on minimizing form errors in additive manufacturing. It discusses how process parameters like slice thickness, orientation, and supports can impact form errors like staircase effect, cylindricity, and flatness. Adaptive slicing, optimized orientation, and contour shaping are presented as methods to reduce specific form errors. The effects of slice thickness and orientation on cylindricity error and build time are experimentally tested. Optimizing process parameters can improve geometric accuracy and surface finish of additively manufactured parts.

![Contour Shaping

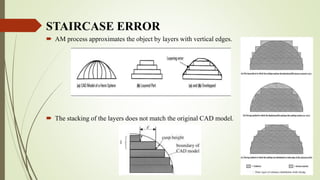

The undesirable feature from the staircase effect is primarily due to the layer edge being

vertical in most LM processes.

The “stair-stepped” effect can only be combated by contouring the actual edge of each layer

to match that of the actual desired part geometry.

The approach taken with the CAM-LEM project [Cawley et. al, 1996],[Zheng et al., 1996] is

to use sloped rather than vertical edges. The CAM-LEM process uses a high-powered laser

with a 5-axis positioning system to machine sloped surfaces on the edges of each layer.](https://image.slidesharecdn.com/minimizationofformerrorsinadditivemanufacturing-140908053751-phpapp01/85/Minimization-of-form-errors-in-additive-manufacturing-19-320.jpg)