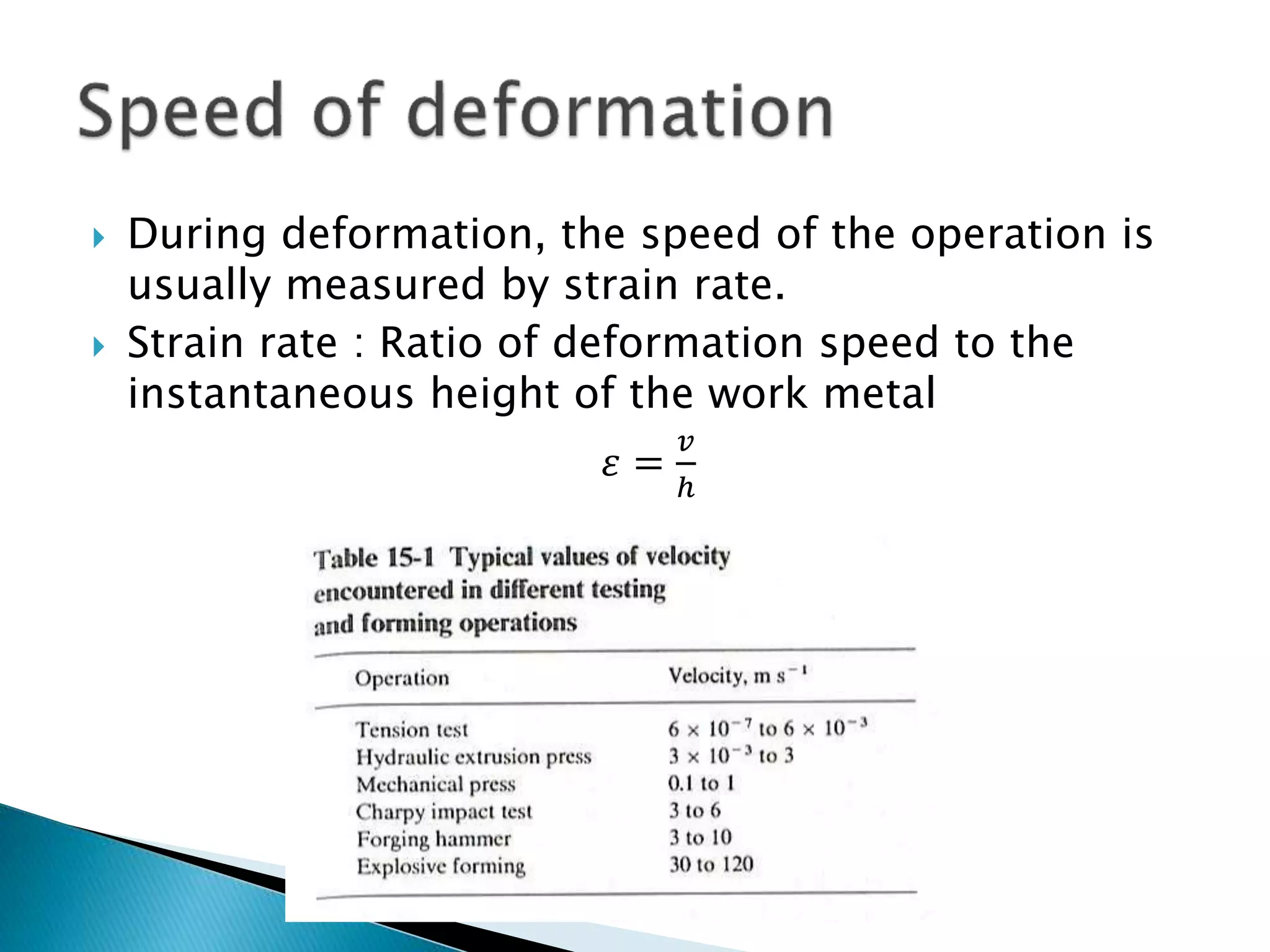

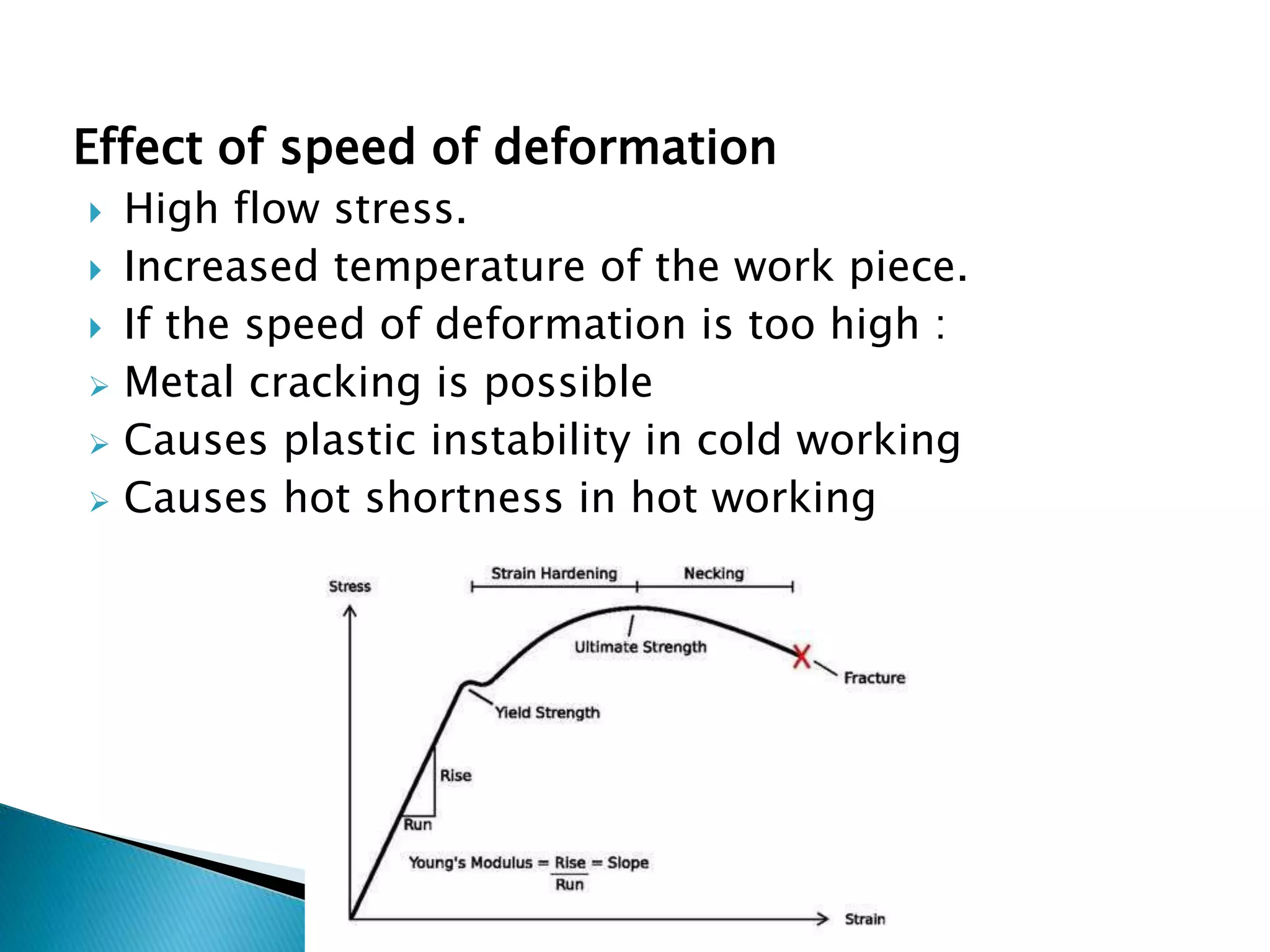

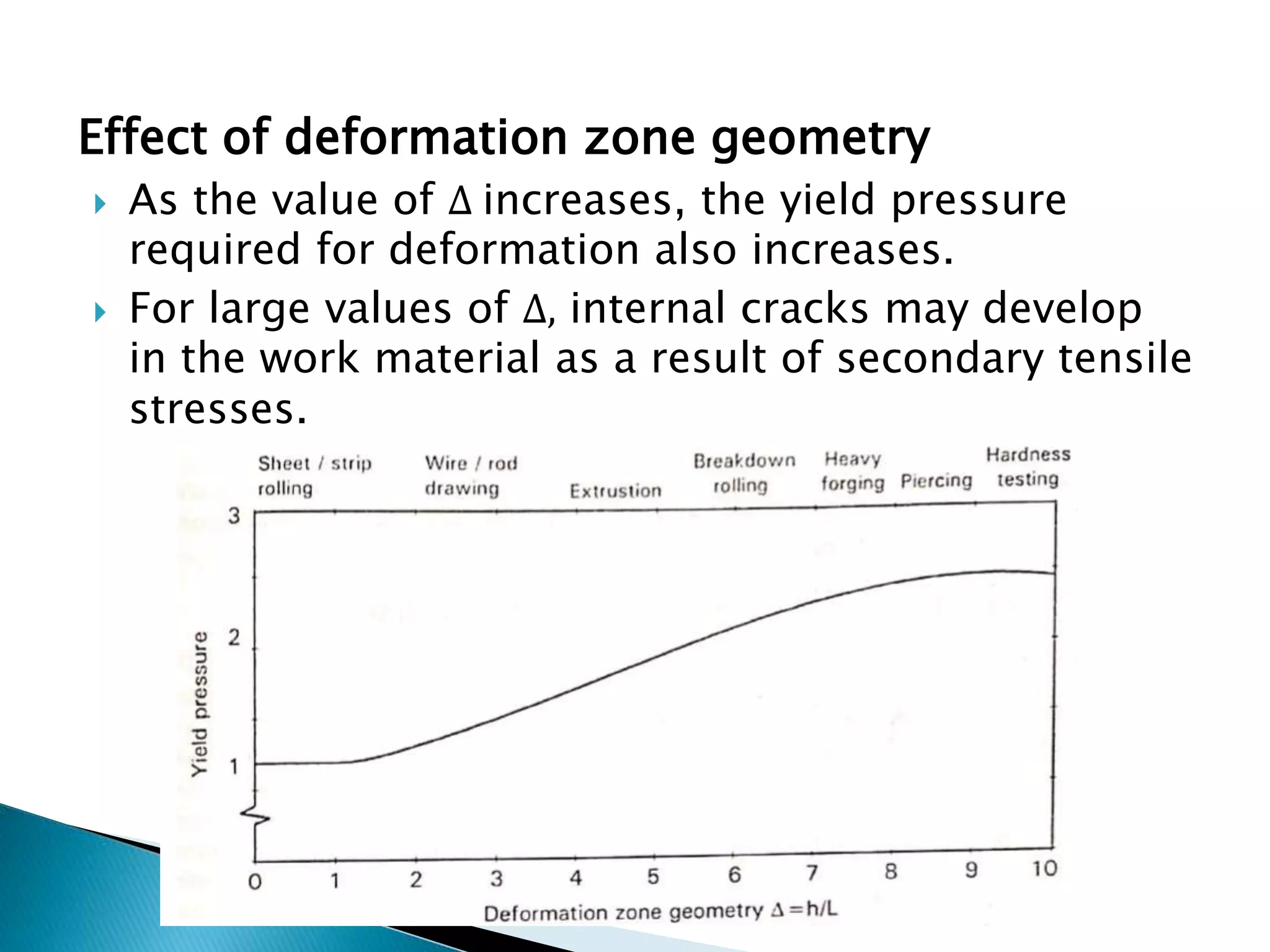

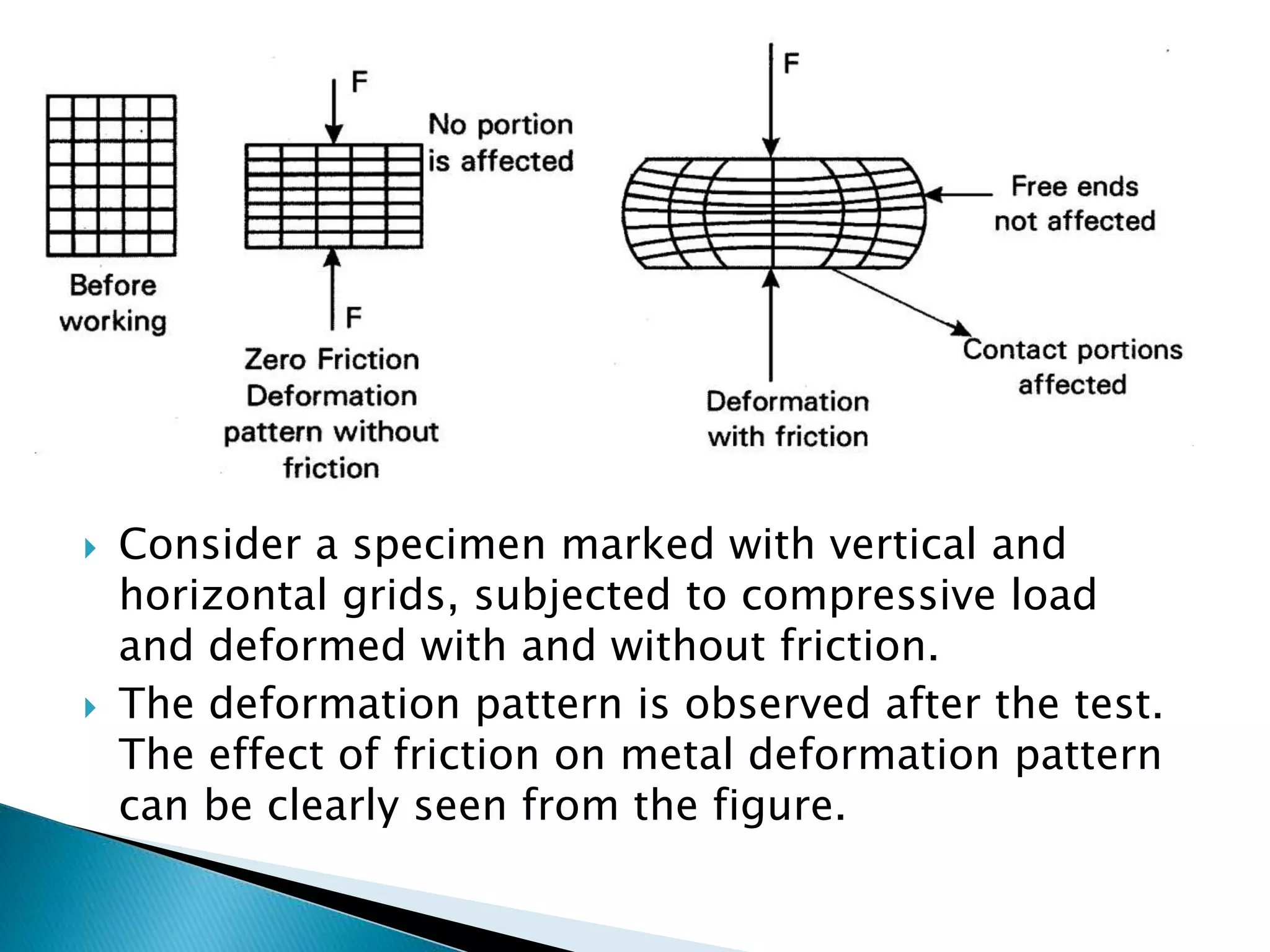

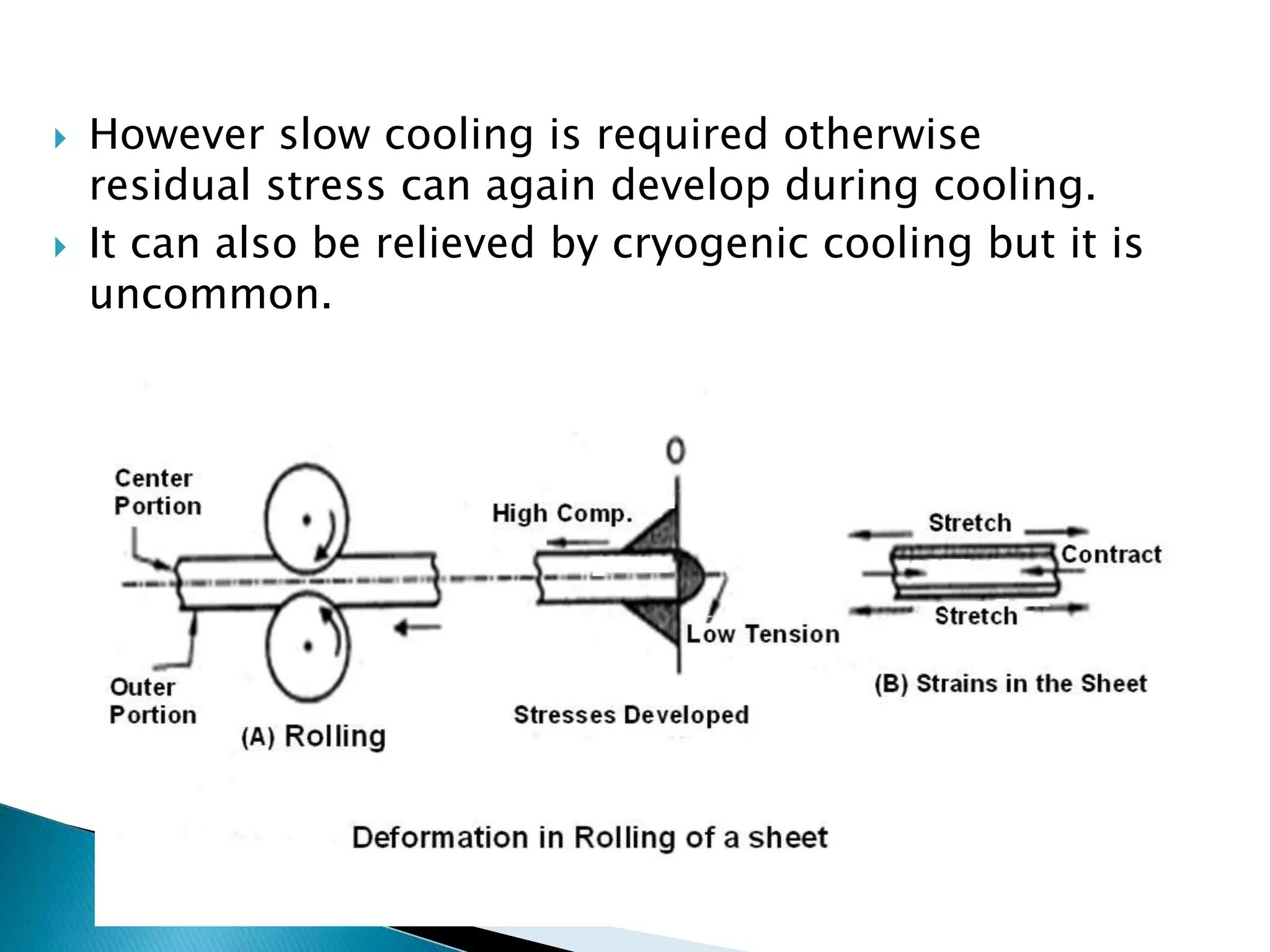

The presentation discusses the effects of various factors on metal forming processes, including the speed of deformation, deformation zone geometry, friction, and residual stress. These factors significantly influence the quality and characteristics of the formed metal, affecting aspects like flow stress, internal crack formation, and ductility. The document also emphasizes how friction can lead to inhomogeneity and wear, while residual stresses can distort components during and after processing.