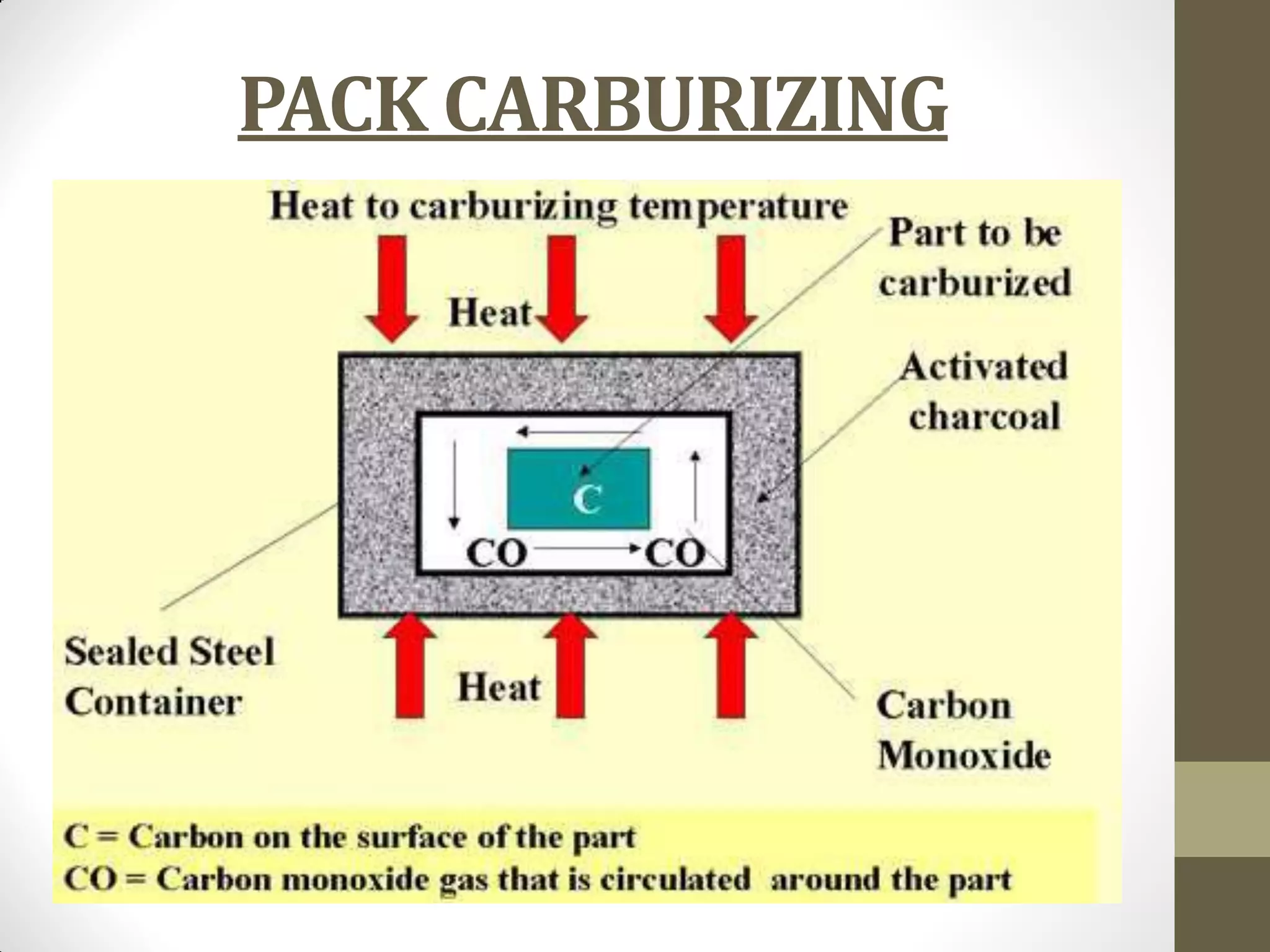

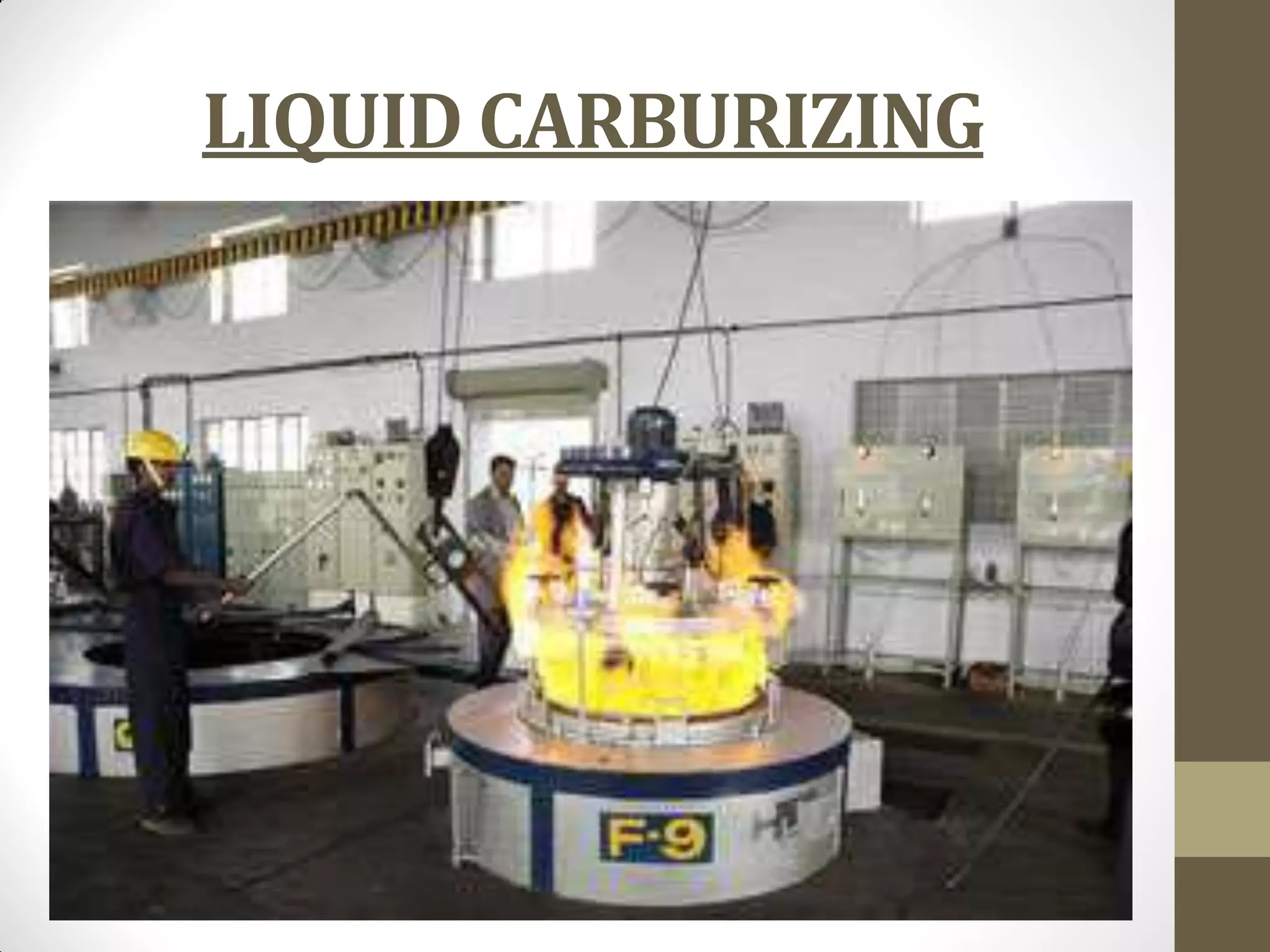

The document presents an overview of carburizing, a heat treatment process that enhances the surface properties of metals by increasing carbon content. It describes various types of carburizing methods, including gas, vacuum, pack, and liquid carburizing, along with their advantages, disadvantages, and applications in different mechanical components. The conclusion emphasizes the significant impact of carburizing on improving the toughness, hardness, and overall mechanical properties of steels.