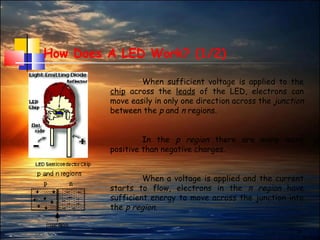

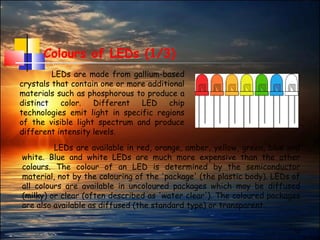

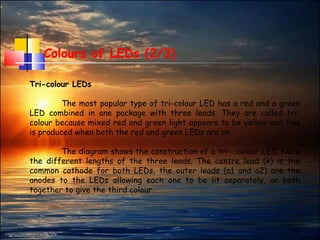

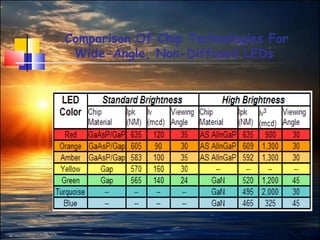

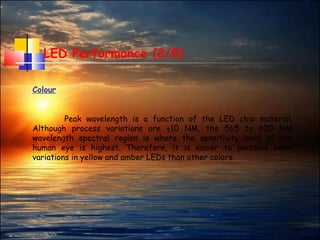

LEDs emit light when electrons recombine with positive charges in the semiconductor material. The color emitted depends on the material used, with common colors being red, green, and blue. LEDs are more energy efficient than incandescent lights and have a longer lifespan. They have many applications including displays, lights, and indicators in devices.