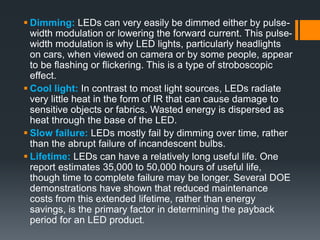

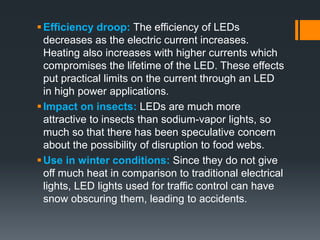

An LED is a semiconductor device that emits light when electric current passes through it. It consists of a chip with a p-n junction, where electrons recombine with holes to release energy in the form of photons. When a suitable voltage is applied, electrons cross the junction and recombine, emitting light. LEDs have advantages over incandescent bulbs like lower energy use, longer lifetime, smaller size, and durability. They have applications in displays, lighting, and indicators. However, LEDs also have disadvantages like higher initial cost and sensitivity to temperature.