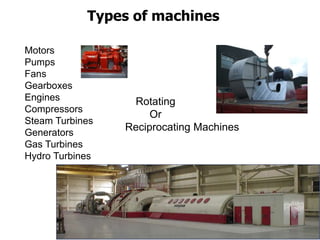

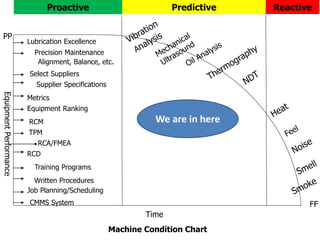

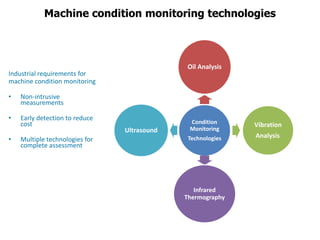

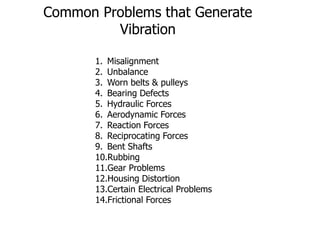

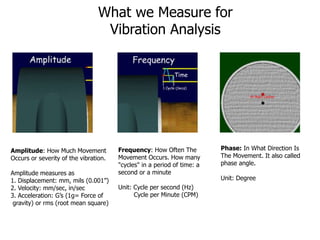

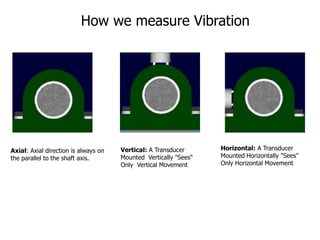

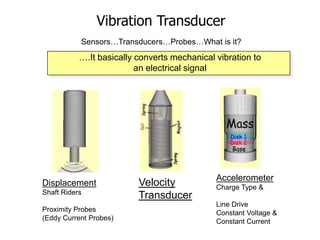

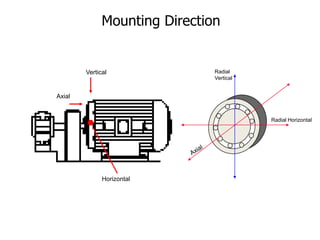

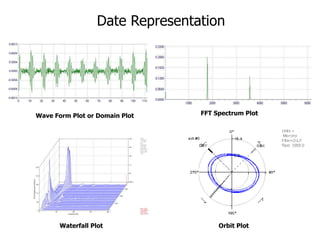

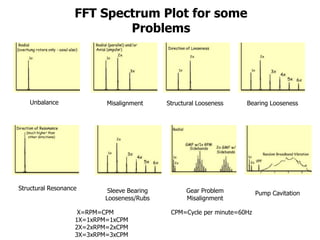

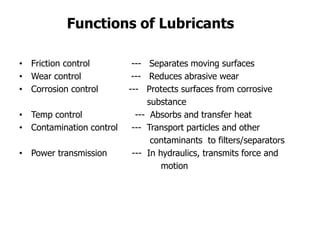

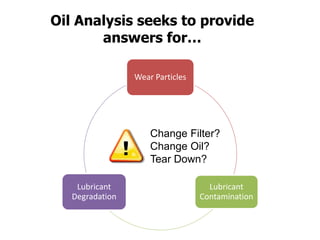

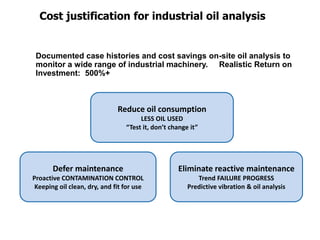

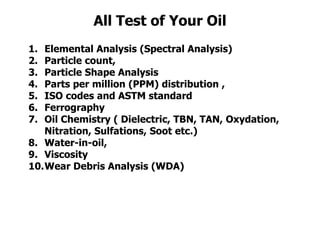

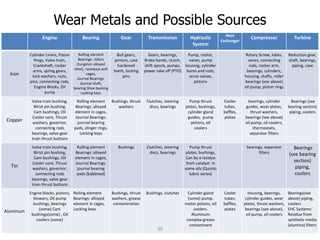

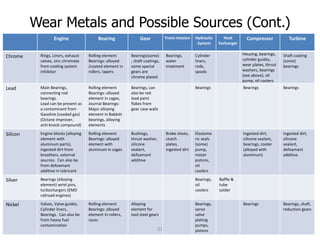

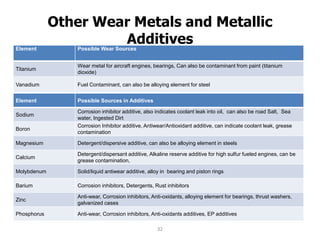

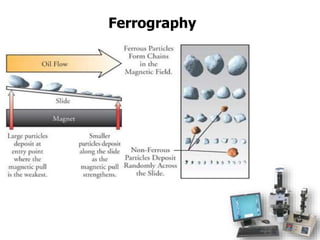

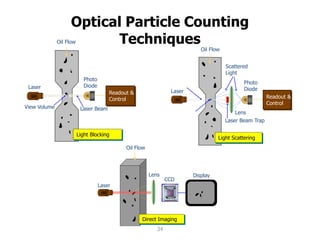

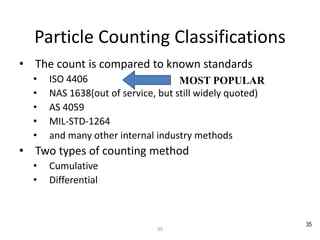

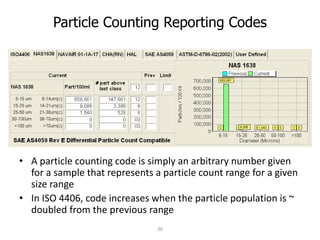

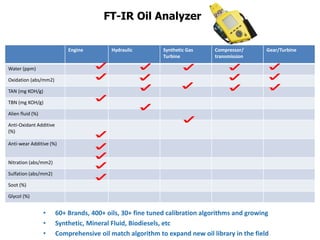

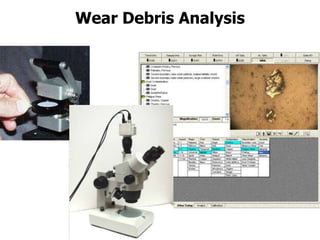

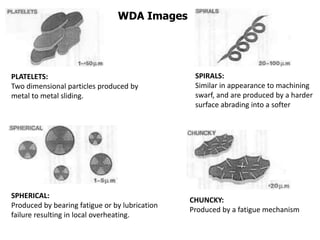

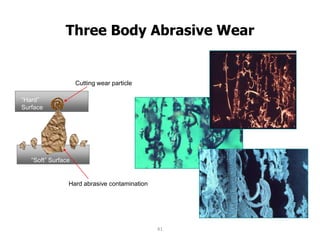

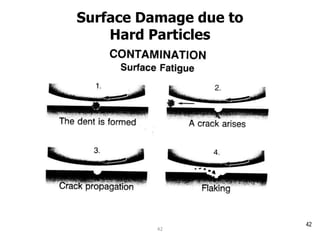

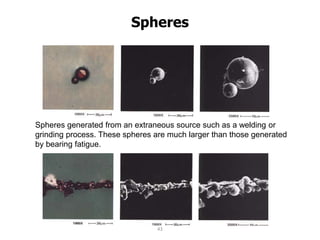

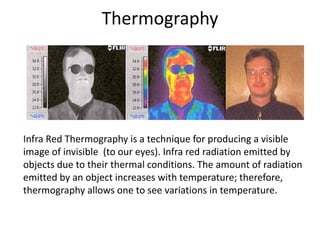

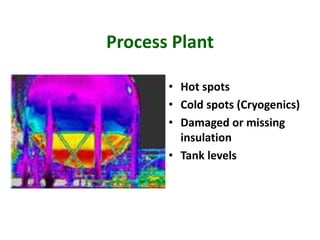

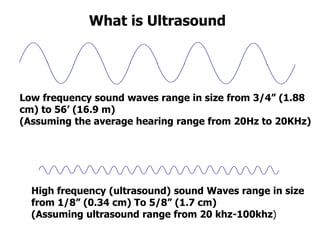

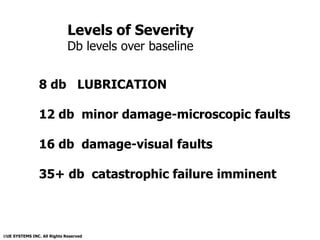

This document provides information on condition monitoring technology for machinery. It discusses vibration analysis, oil analysis, ultrasound analysis, and thermal analysis as the key condition monitoring technologies. It describes common machine problems that can be detected by vibration analysis like misalignment, unbalance, bearing defects, and gear problems. It provides details on vibration measurement, oil analysis tests, particle counting classifications, and wear debris analysis. The overall document is about condition monitoring techniques and technologies to monitor machine health and enable predictive maintenance.