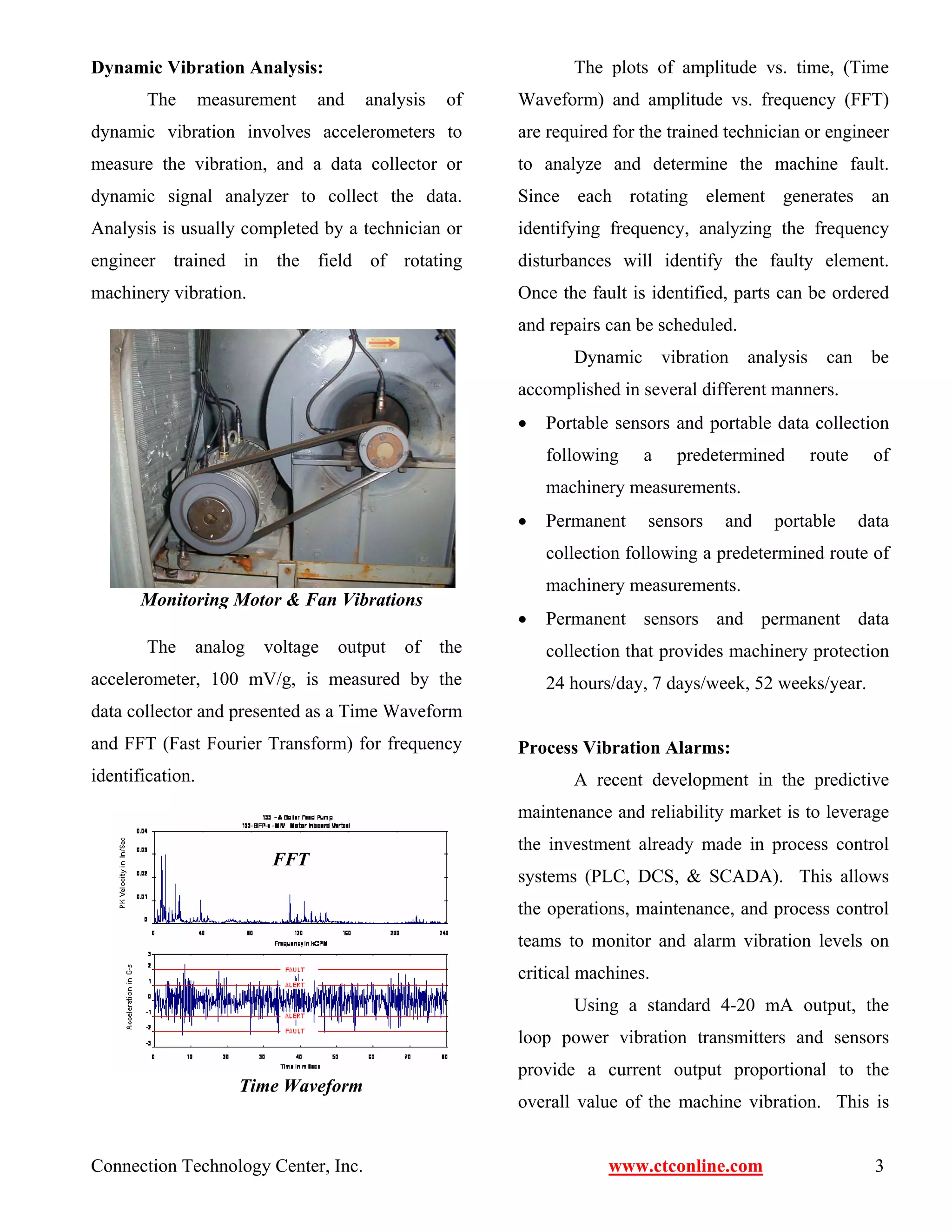

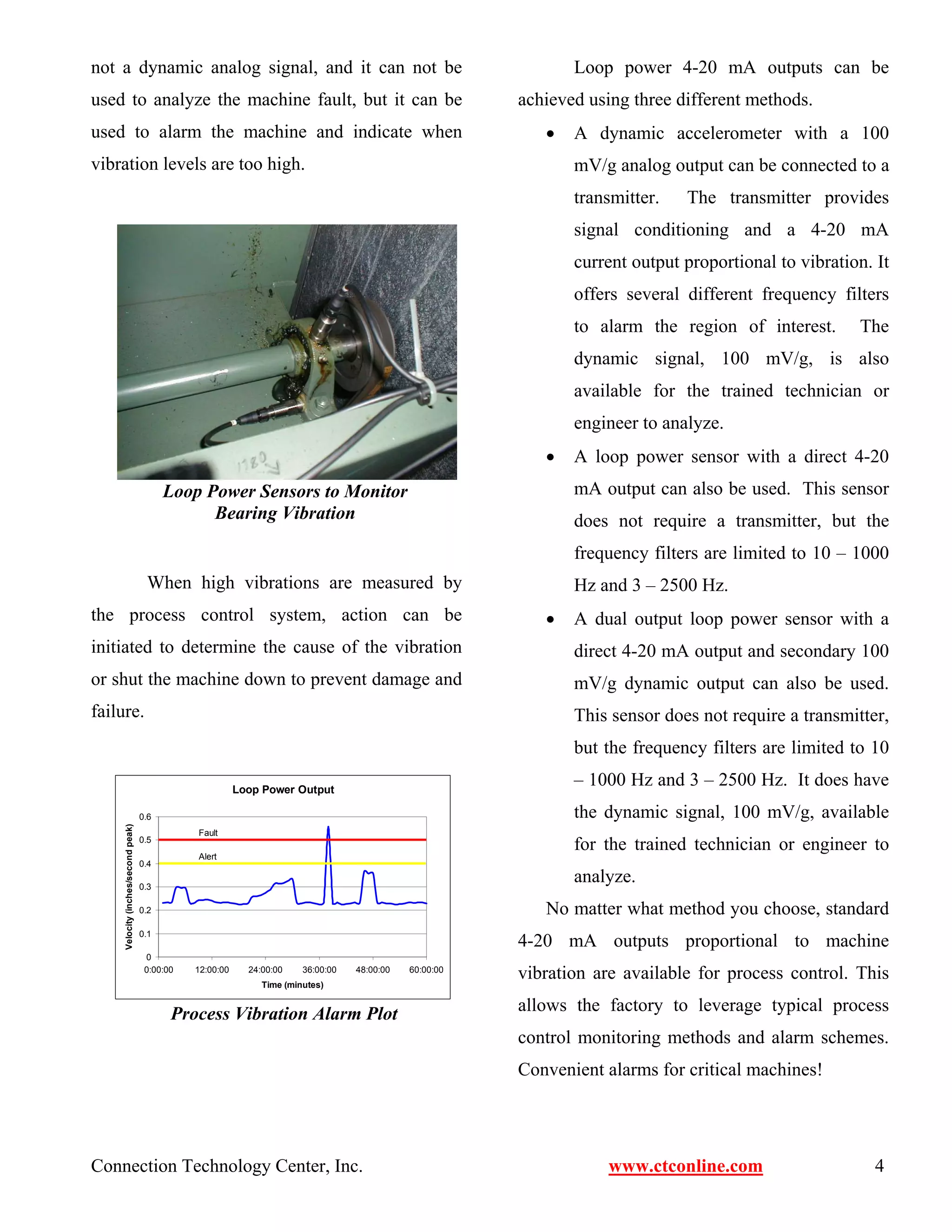

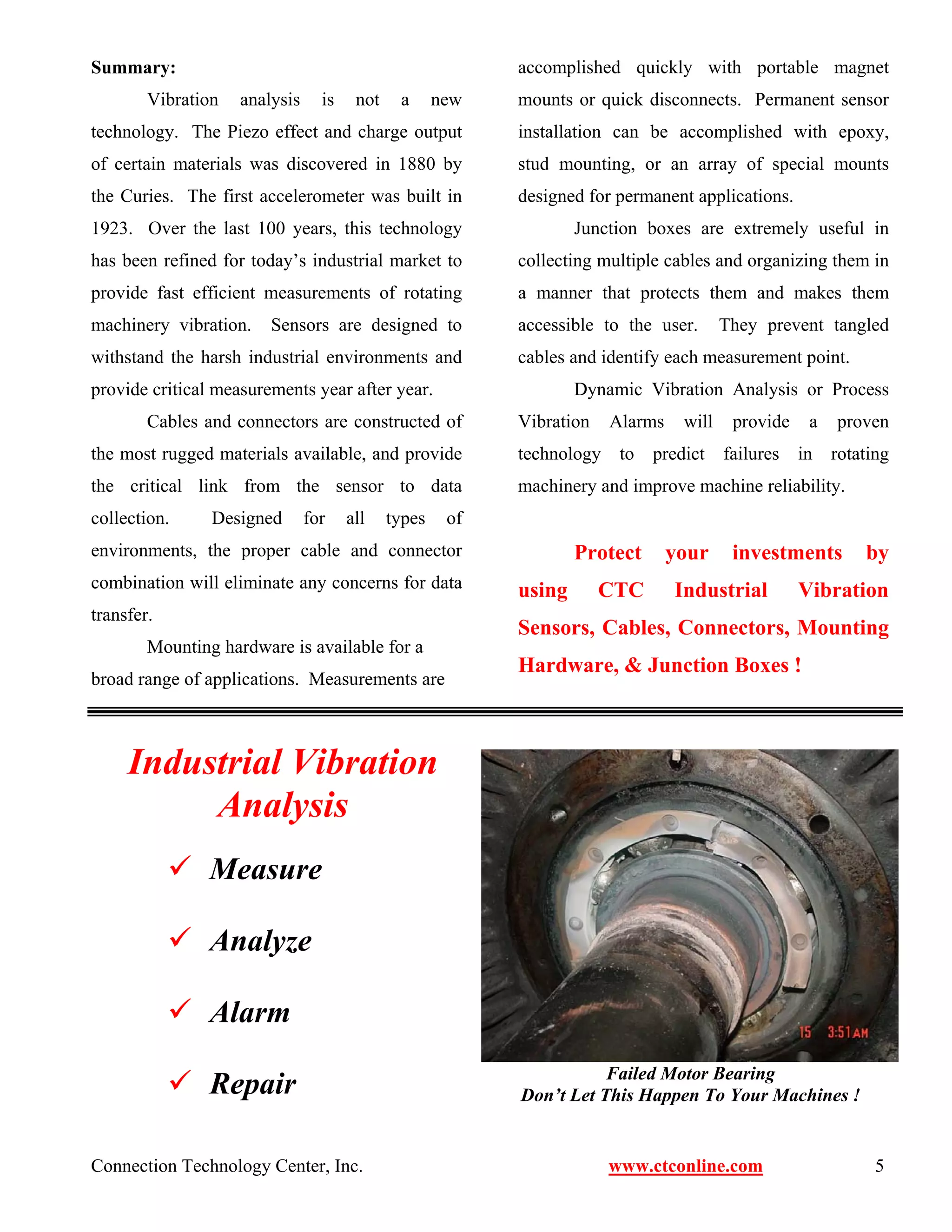

Vibration analysis uses sensors to measure vibrations in machines and identify potential failures or faults. Analyzing vibration data can help predict maintenance needs and improve machine reliability. Sensors are mounted on machines using various methods to measure vibrations generated by rotating components like motors, pumps and gears. The vibration measurements are analyzed to diagnose issues and plan repairs for machines before failures occur.