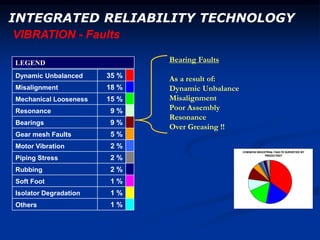

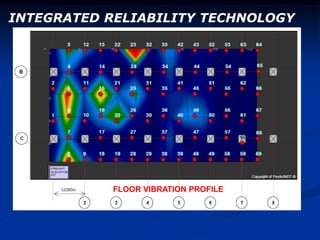

The document discusses integrated reliability technology focusing on vibration analysis and diagnostics in various industries, highlighting common industrial faults such as dynamic unbalance, misalignment, and mechanical looseness. It emphasizes the importance of vibration monitoring and corrective maintenance to improve equipment reliability and reduce maintenance costs, particularly in marine and oil & gas sectors. Statistical data from surveys illustrates the extent of these issues and their impact on machinery performance and maintenance strategies.